Energy-saving type boiler ultralow-load combustion stabilization system

An energy-saving boiler technology, applied in the control system, combustion method, combustion equipment, etc., can solve the problems of poor flame stability, blasting, and temperature drop, so as to promote ignition and burnout, improve the adaptability of pulverized coal, and improve the efficiency of boilers. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

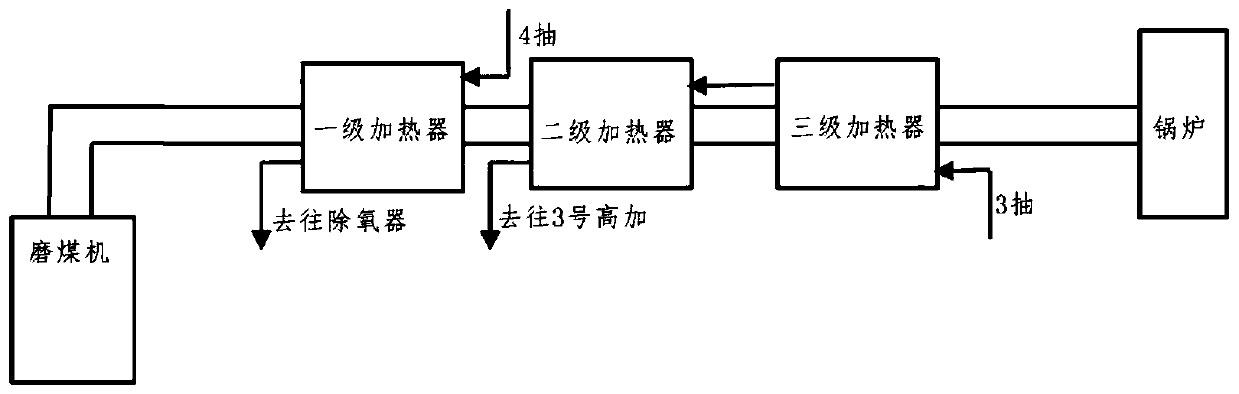

[0023] Such as figure 1 As shown, the energy-saving boiler ultra-low load stable combustion system provided in this embodiment is suitable for the single-channel pulverized coal heater system of the dry pulverization system. A three-stage steam heat exchanger is added to the pulverized coal pipeline between the coal mill and the boiler. The pulverized coal pipeline from the coal pulverizer is connected to the first-level heater, the second-level heater, and the third-level heater in sequence, and then enters the boiler. .

[0024] Extraction 4 (No. 4 extraction pipeline) is connected to the steam side inlet of the primary heater, and the steam side outlet of the primary heater is connected to the deaerator. 3 extraction (No. 3 extraction pipeline) is connected to the steam side inlet of the third stage heater, and the steam side outlet of the third stage heater is connected to the steam side inlet of the second stage heater through the steam pipeline, and the steam side outle...

Embodiment 2

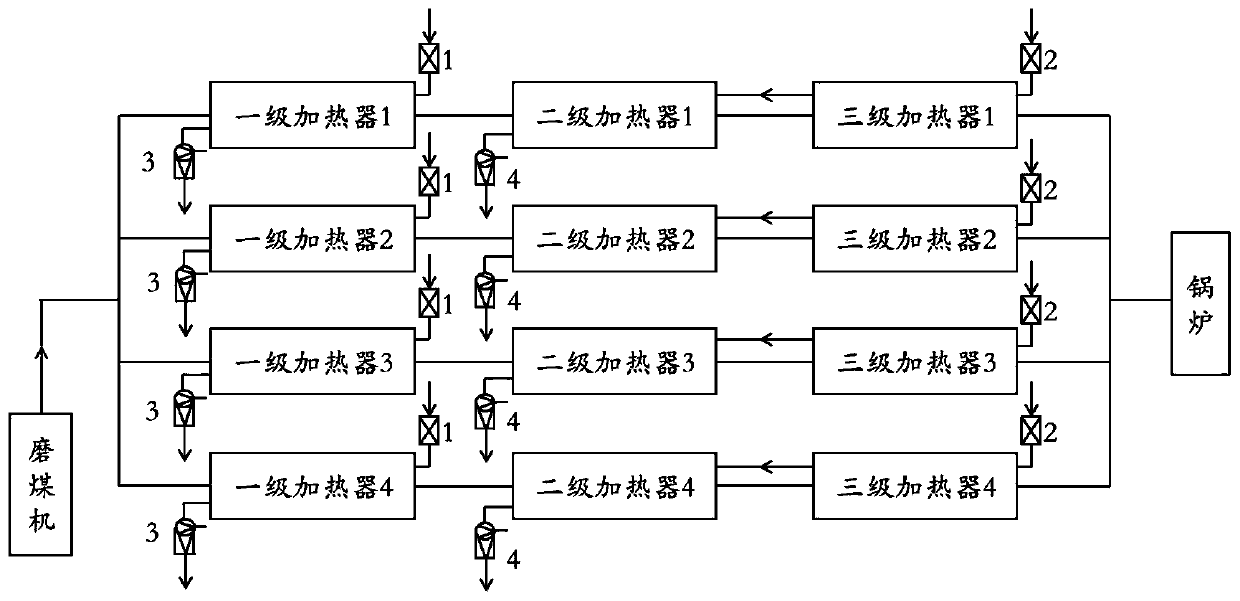

[0029] Such as figure 2 As shown, the energy-saving boiler ultra-low-load stable combustion system provided in this embodiment is suitable for the pulverized coal heater system connected to a single coal pulverizer of the dry pulverization system. Three-stage steam heat exchangers are respectively added to the four pulverized coal pipes between the coal mill and the boiler, and the four pulverized coal pipes coming out of the coal mill are connected to the first-stage heaters 1 / 2 / 3 / 4, The secondary heater 1 / 2 / 3 / 4 and the tertiary heater 1 / 2 / 3 / 4 are connected to the boiler.

[0030] 4 extraction (No. 4 extraction pipeline) is connected to the steam side inlet of the primary heater 1 / 2 / 3 / 4, and the steam side outlet of the primary heater 1 / 2 / 3 / 4 is connected to the deaerator. 3 extraction (No. 3 extraction pipeline) is connected to the steam side inlet of the tertiary heater 1 / 2 / 3 / 4, and the steam side outlet of the tertiary heater 1 / 2 / 3 / 4 is connected to the secondary heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com