Ammonia-mixed fuel thermal power generation system and method

A fuel and ammonia supply technology, applied in the combustion method, fuel supply, combustion air/fuel supply, etc., can solve the problems of high nitrogen oxide emission, low flame speed, reduced boiler efficiency, etc., to promote burnout, ensure Combustion efficiency and the effect of improving boiler thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

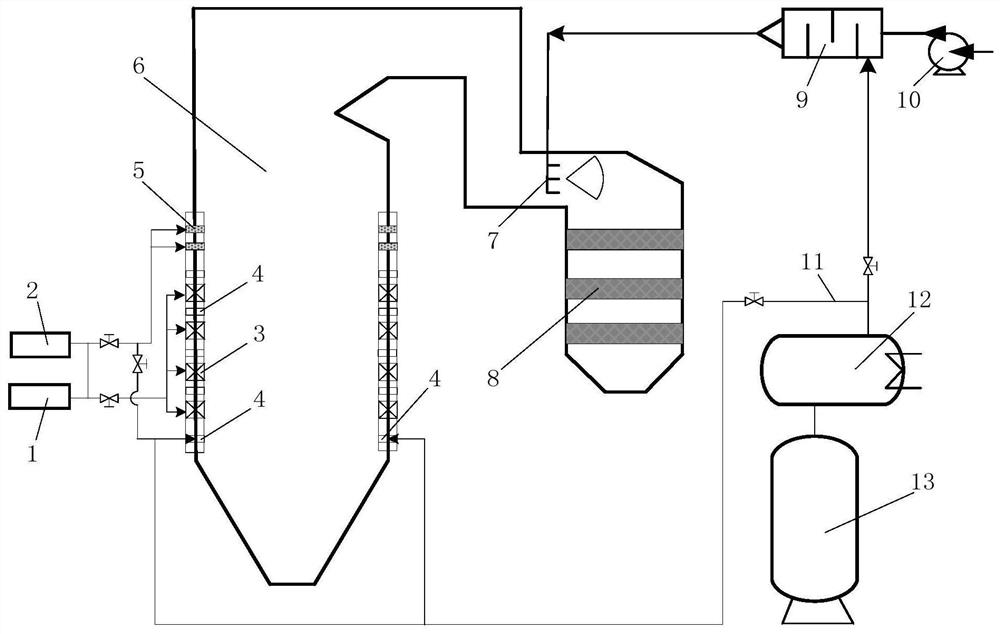

[0027] A mixed ammonia fuel thermal power generation system of the present invention uses ammonia and coal powder to generate electricity through mixed combustion, such as figure 1 As shown, it includes a boiler 6, an ammonia supply system connected to the boiler 6, a pulverized coal pipeline 1 and an air pipeline 2;

[0028] The side wall of the furnace of the boiler 6 is sequentially provided with an overburning air nozzle 5, a secondary air nozzle 4 and a primary air nozzle 3 from top to bottom, and an SCR reactor 8 is arranged at the tail flue of the boiler 6;

[0029] The secondary air spout 4 and the primary air spout 3 are arranged at intervals along the furnace side wall, and the primary air spout 3 is arranged between adjacent secondary air spouts 4;

[0030] The pulverized coal pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com