Burner for gas stove and gas stove

A gas stove and burner technology, which is applied in the directions of gas fuel burners, burners, combustion methods, etc., can solve the problems of the complex structure of the fixed bracket, the influence of the ejection effect, and the change of the distance between the ejection tube and the nozzle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

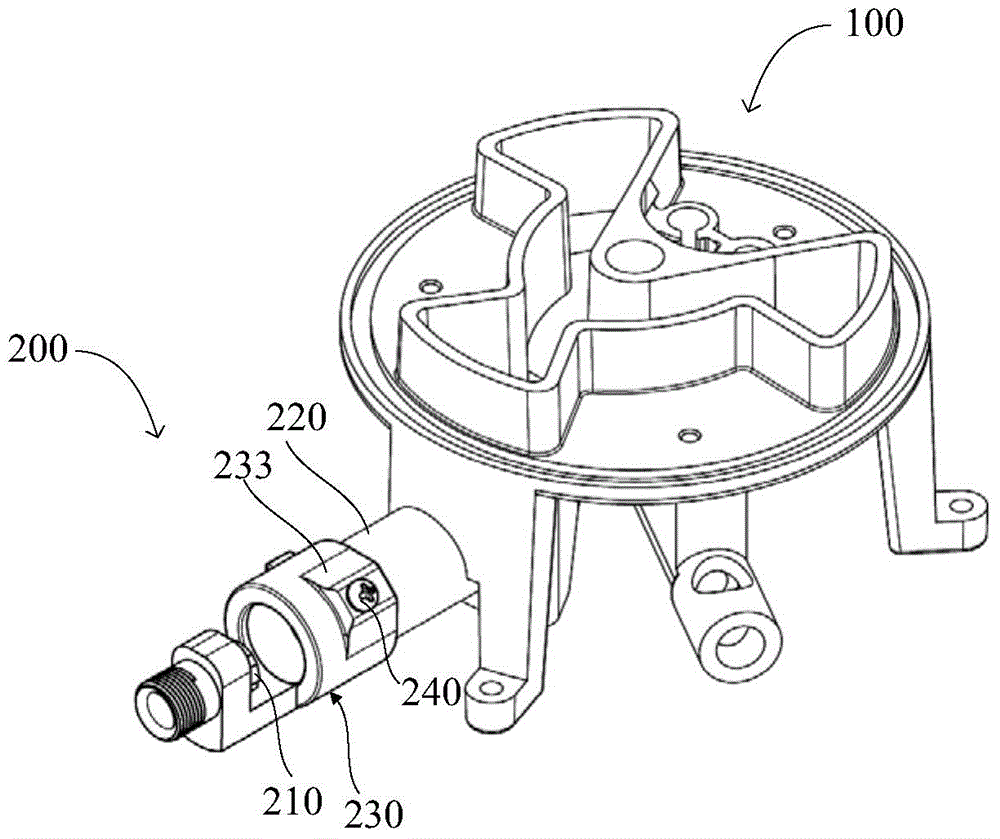

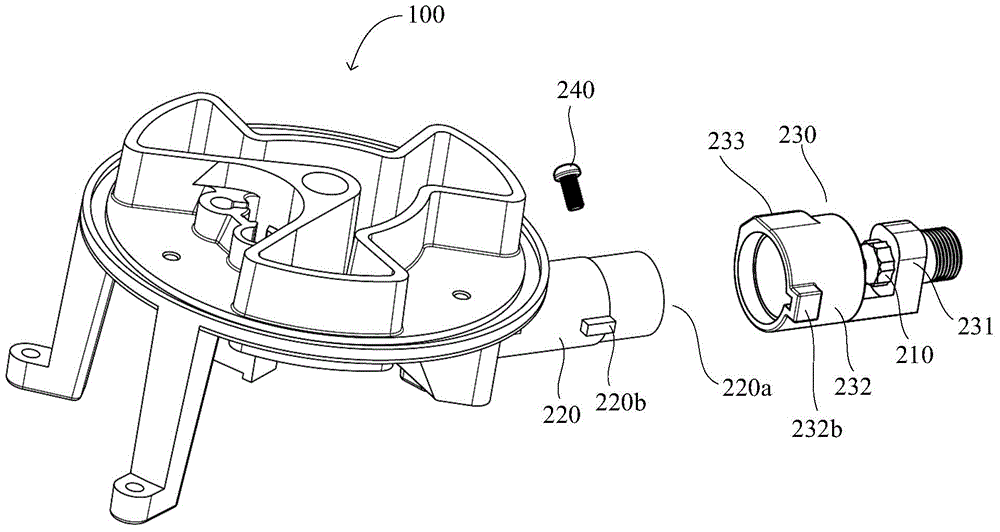

[0029] An embodiment of the present invention provides a burner, referring to Figure 2-5 As shown, it includes a burner base 100 and an injection device 200 connected to the burner base 100 . The injection device 200 mixes gas and air according to a certain ratio and delivers them to the burner base 100 .

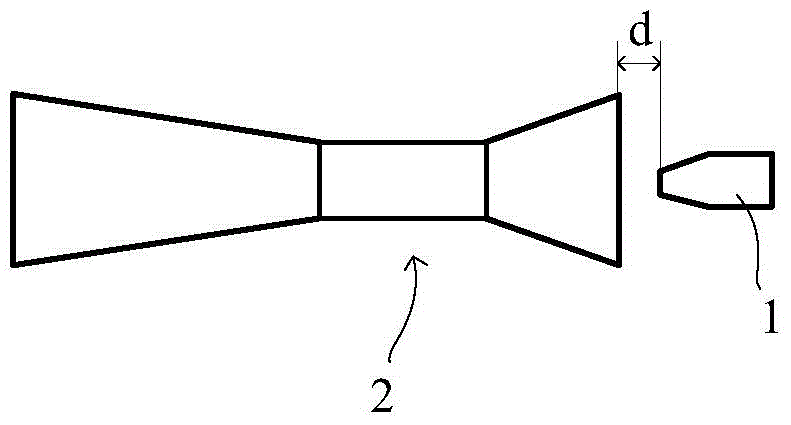

[0030] The injection device 200 includes a nozzle 210 , an injection tube 220 and a fixing bracket 230 , the injection tube 210 is integrally formed on the burner base 100 , and the fixing bracket 230 is used for connecting the nozzle 210 and the injection tube 220 . Wherein, the spout 210a of nozzle 210 ( Figure 4 ) is aligned with the entrance 220a of the injection tube 220 ( image 3 , Figure 4 ), there is a gap between the noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com