Compound combustion beam for lime kiln

A technology of combustion beams and lime kilns, which is applied in the field of composite combustion beams and combustion beams for lime kilns. It can solve the problems of reduced quality of calcined products and inability to adapt to fuel switching, so as to increase operational flexibility, improve quality of lime products, and improve usage. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

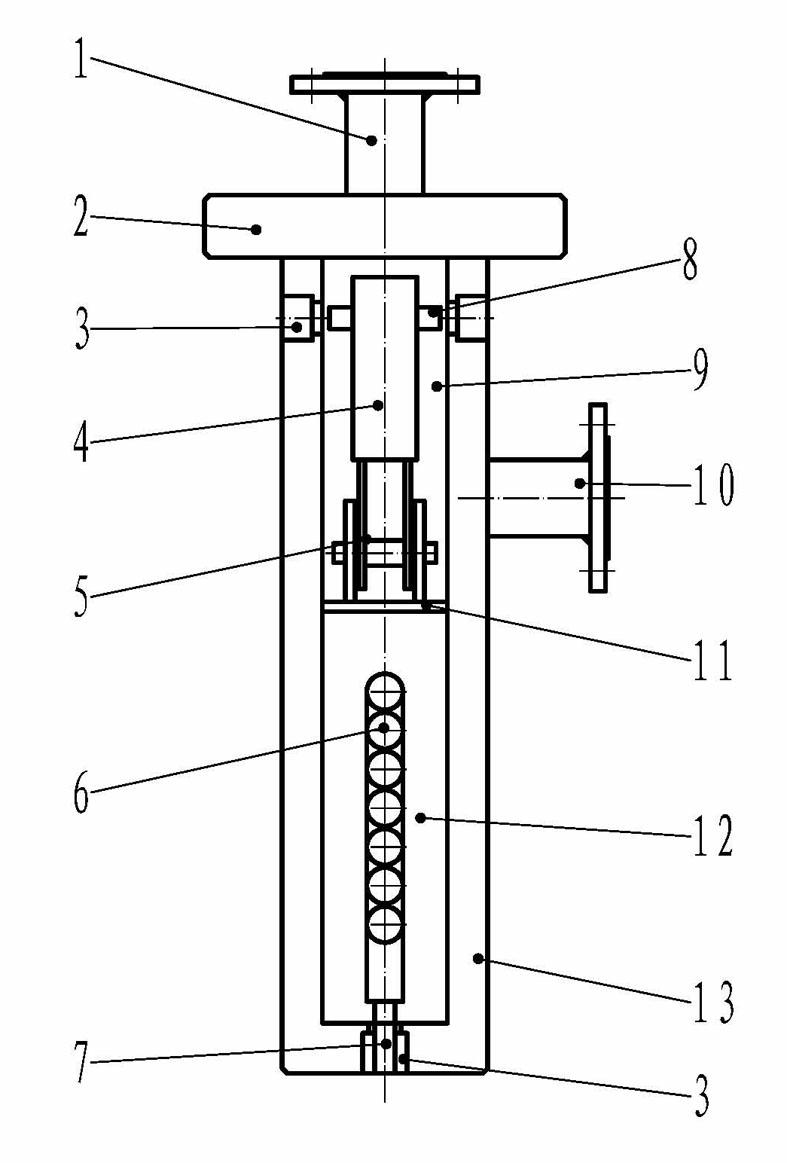

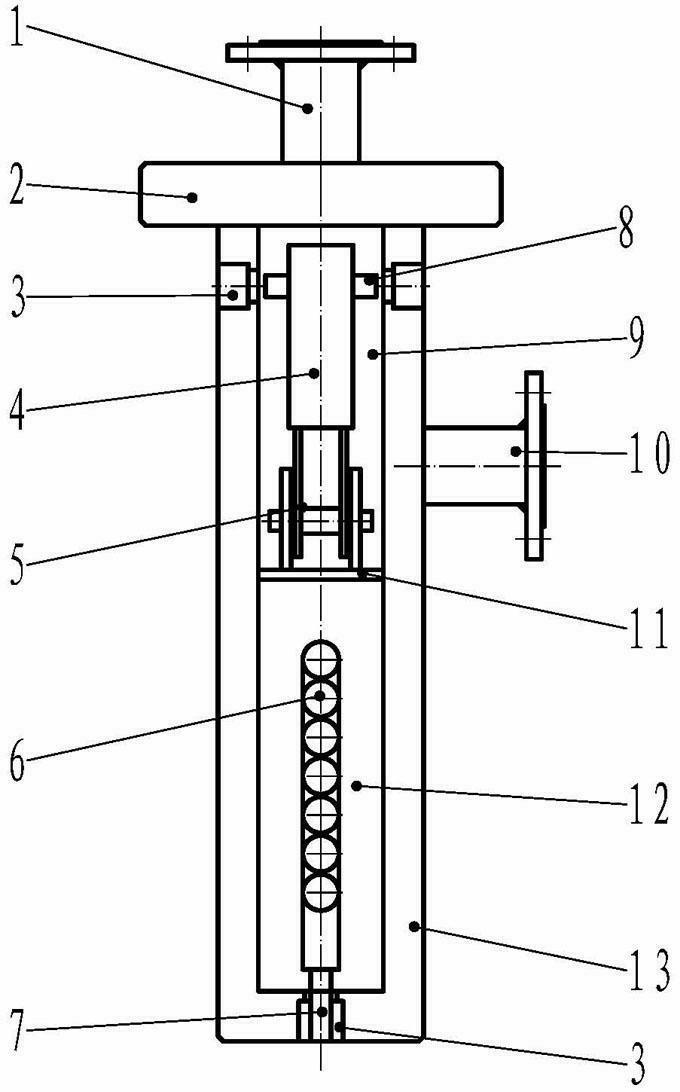

[0011] Lime kiln composite combustion beam of the present invention, as figure 1 Shown, be made of beam body 13, burner 3 and T-shaped cover 2, described burner is positioned at the both sides and the bottom of beam body, and each side is provided with 10 burners, and the bottom is provided with 10 burners. The beam body is provided with a cavity for heat transfer oil circulation, and the cavity for heat transfer oil circulation is connected with the heat transfer oil inlet 10 and the heat transfer oil outlet 1, and the inlet and outlet of the heat transfer oil are connected with the heat transfer oil circulation system, which is used to cool the burning beam body and avoid high temperature Burn out burning beams and beam body equipment. The beam body is divided into upper and lower parts by a partition 11. The upper part of the beam body includes a gas channel 4 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com