Fine coal dense phase conveying system of fusion reducing furnace

A technology of conveying system and reduction furnace, which is applied in the field of gas phase transmission of powder and granular materials, and can solve the problems of high maintenance cost, high investment, and large maintenance amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

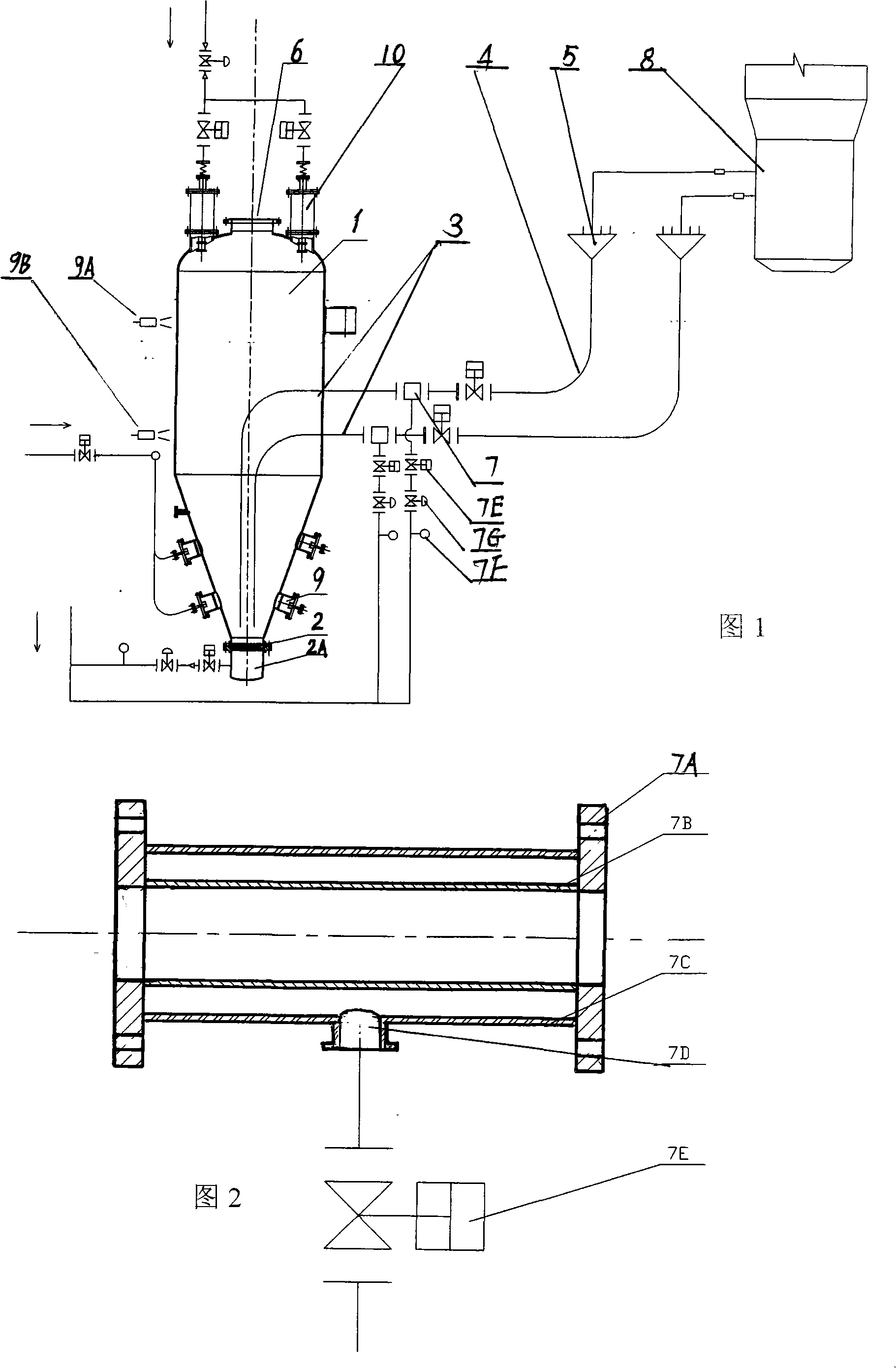

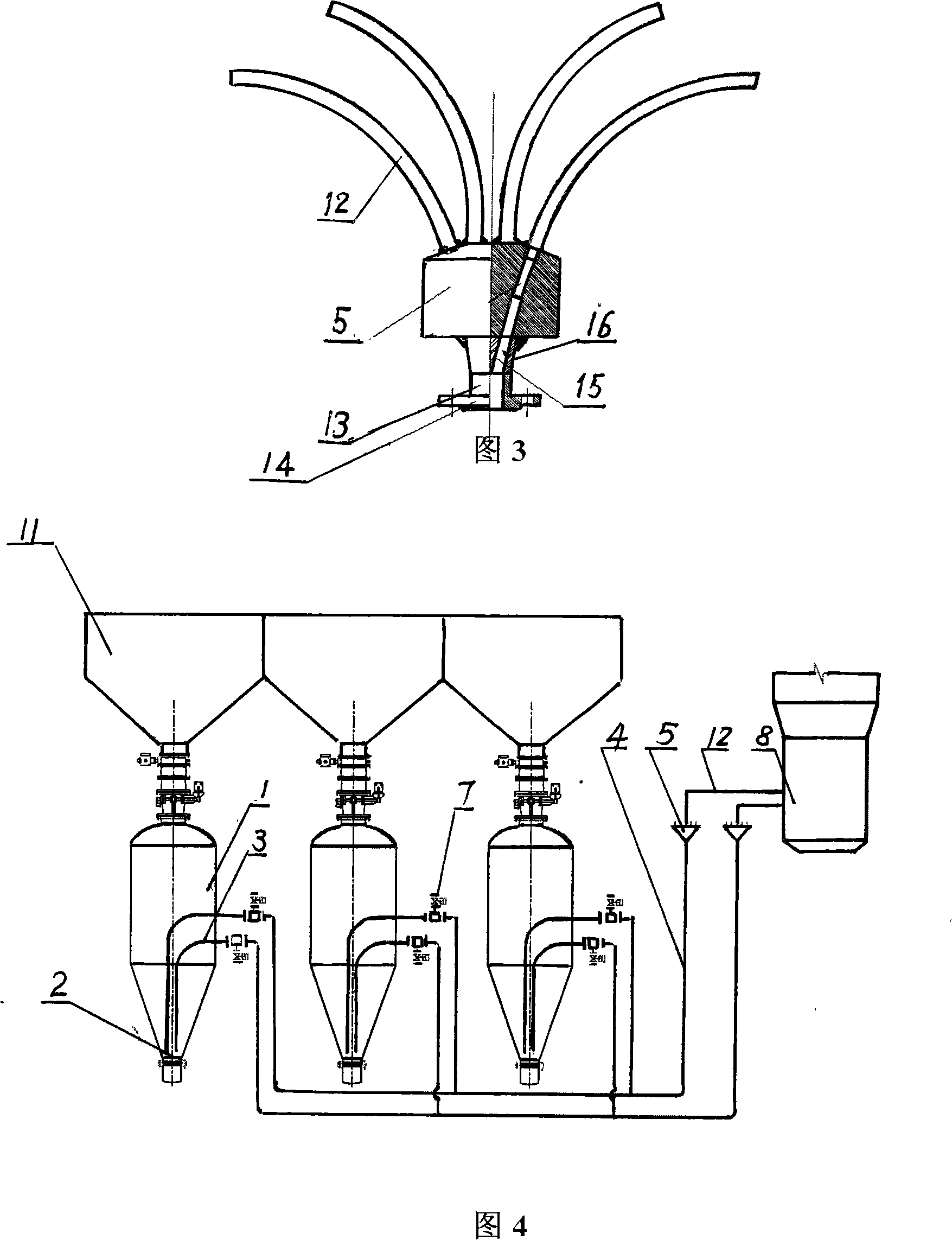

[0026] It can be clearly seen from the accompanying drawings that the system consists of a pulverized coal bunker 11, a fluidized injection tank 1 arranged below the outlet of the pulverized coal bunker 11 and a dense phase pulverized coal distributor 5 arranged in front of the furnace. Each device is connected through a pulverized coal pipeline, and a pulverized coal flow monitor, a nitrogen pressure flowmeter and a flow control device are installed on the pipeline. The key design is that each independent system includes at least two fluidized injection tanks arranged in parallel, and at least one suction pipe 3 is drawn from each independent injection tank 1 to communicate with the supporting coal delivery main pipe 4, respectively. At least two independent coal conveying main pipes 4 are respectively connected with the matching dense-phase pulverized coal distributor 5, and the pulverized coal is fed from the corresponding nozzle on the smelting reduction furnace 8 by means ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com