On-line monitoring system and method for concentration deviation between pulverized coal conveying pipelines of coal mill

A concentration deviation, pulverized coal pipeline technology, applied in measurement devices, suspension and porous material analysis, particle suspension analysis, etc., can solve the problems of limited sensing range of electrostatic induction probe installation and measurement point, problems of representativeness, etc., to simplify The effect of balanced control of pulverized coal concentration, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

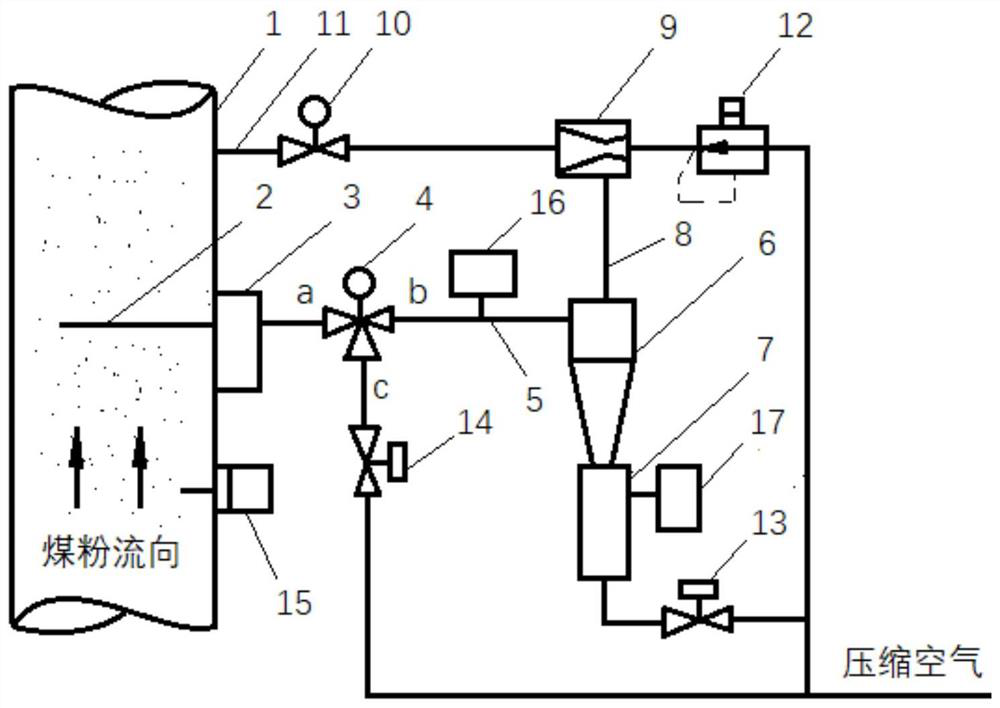

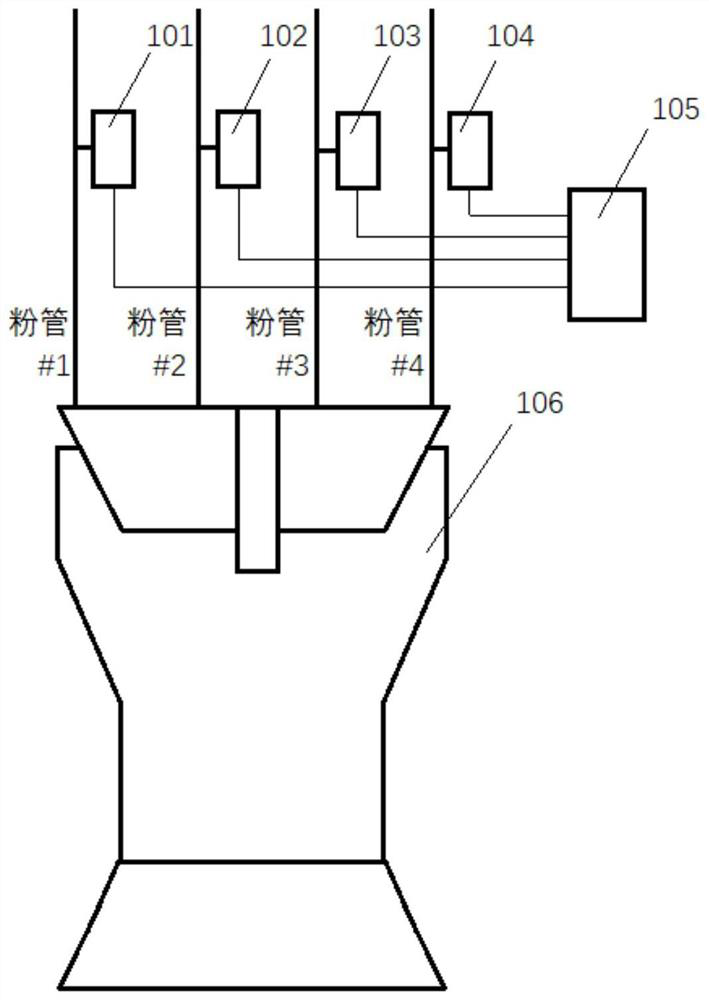

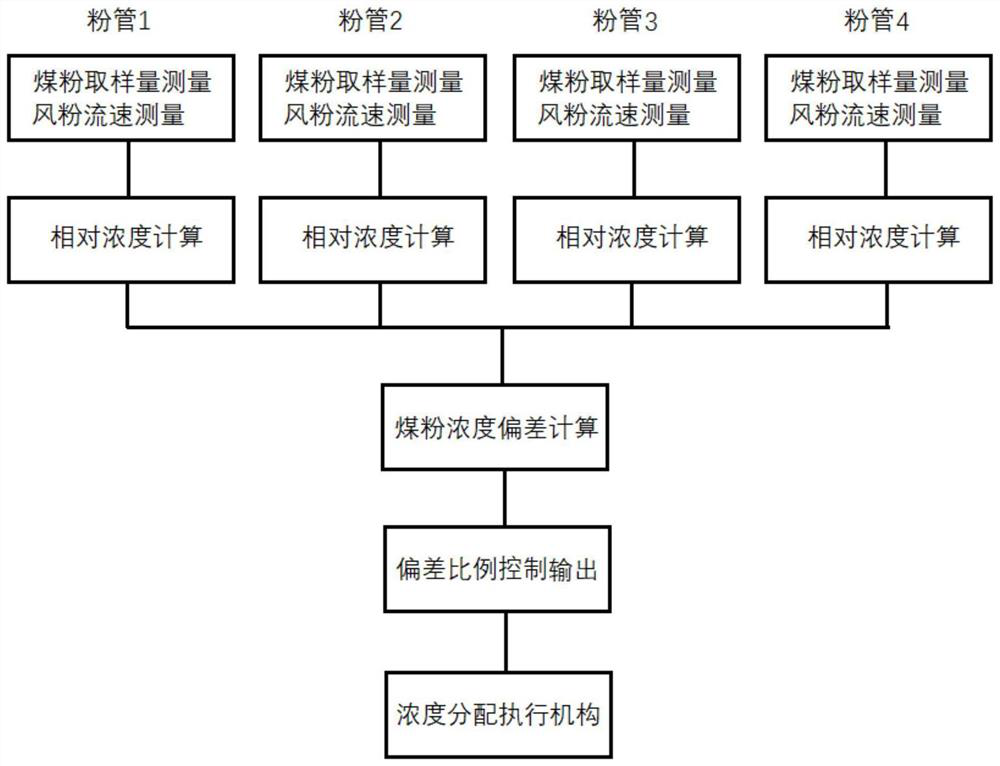

[0041] An on-line monitoring system for concentration deviation between coal pulverizer pipelines, including four online constant-velocity pulverized coal sampling and measuring devices and a system measurement control unit, and the on-line constant-velocity pulverized coal sampling and measuring devices are respectively installed at the outlet of the same coal pulverizer On several pulverized coal pipelines 1, and the online constant velocity pulverized coal sampling and measuring devices are respectively connected to the system measurement control unit through the control signal line. The sampling and measuring device performs logic timing control and processing and transmission of measurement signals. Such as figure 2 As shown, the outlet of a coal mill 106 is equipped with 4 pulverized coal pipes, which are powder pipe #1, powder pipe #2, powder pipe #3, and powder pipe #4. The pulverized coal sampling and measuring devices 101-104 are respectively connected to the syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com