Chemical waste recycling system and method

A waste and chemical technology, applied in the field of waste treatment system, can solve the problems of lower boiler availability, lower boiler safety, lower economic efficiency, etc., and achieve the effect of preventing slagging in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

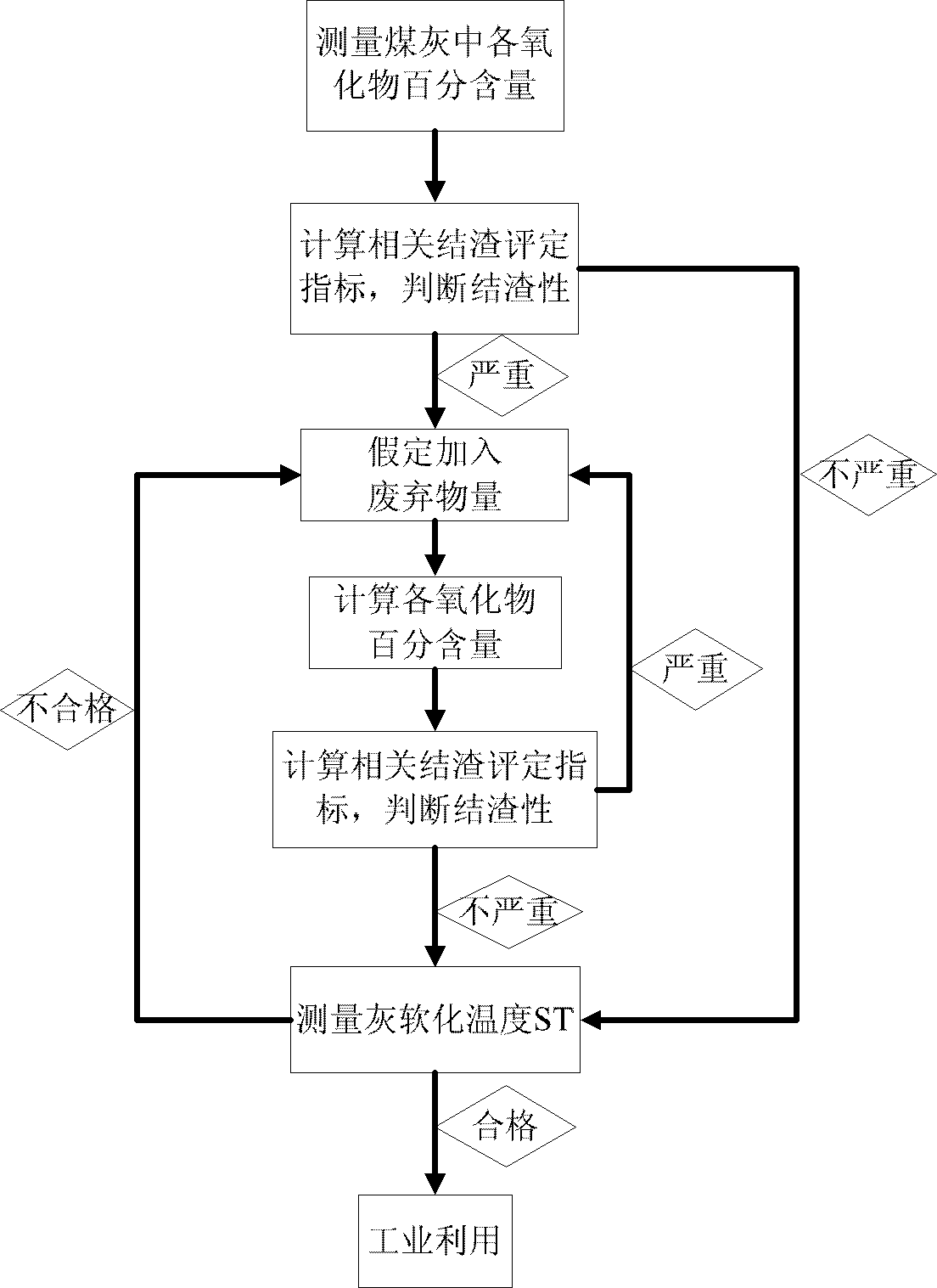

[0022] This scheme can recycle the fly ash produced by waste, and achieve the purpose of alleviating the slagging of power plant boilers.

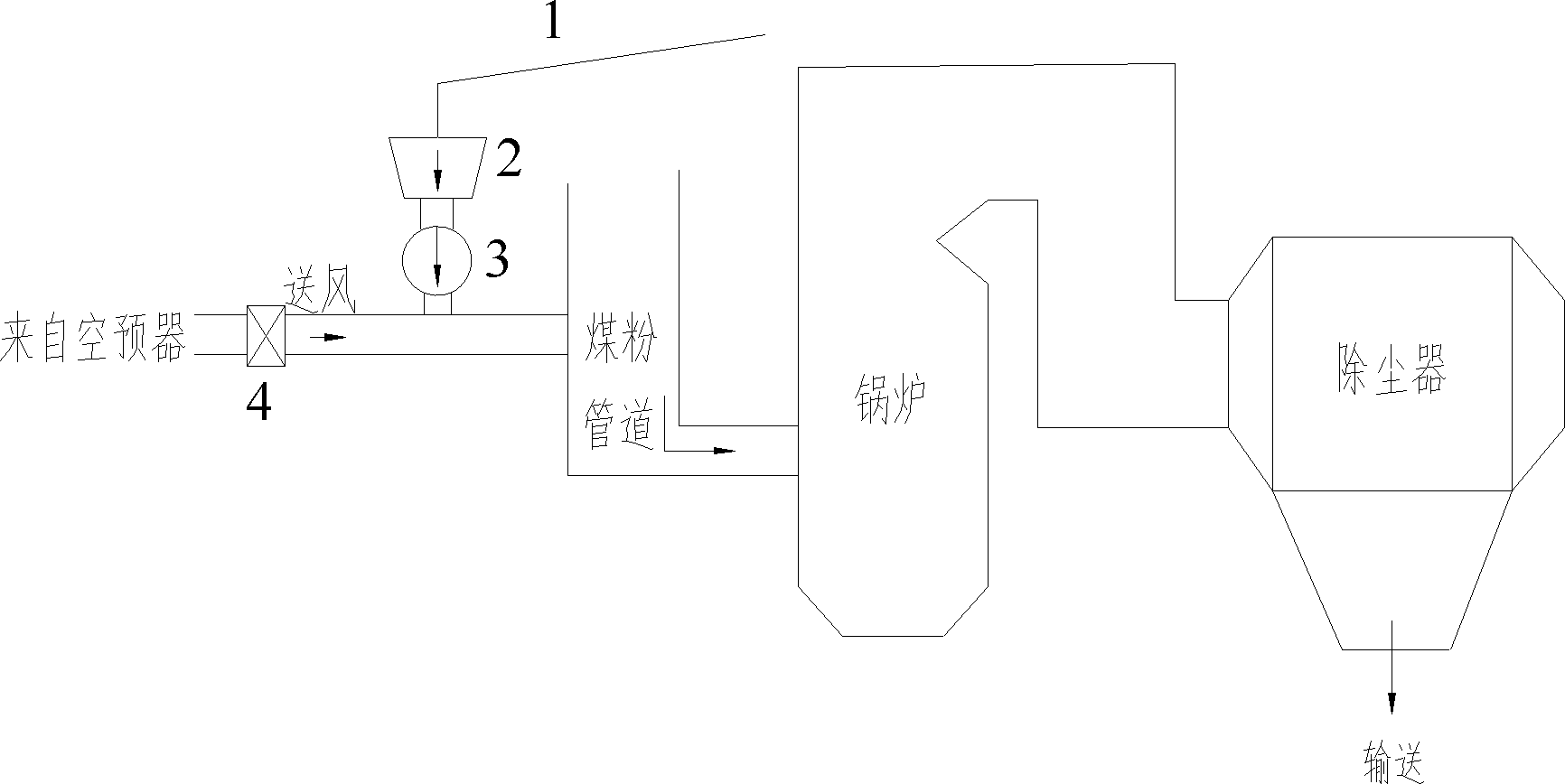

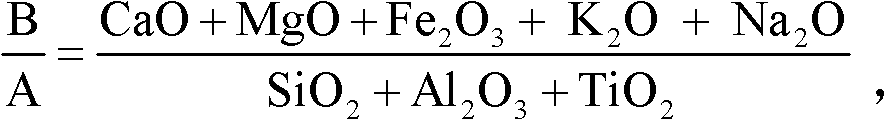

[0023] see figure 1 , the present invention includes an air preheater pipeline for air supply with a pressure regulating valve 4 and a pulverized coal pipeline connected with the air preheater pipeline, the outlet of the pulverized coal pipeline communicates with the feed port of the boiler, and the outlet of the boiler It communicates with the dust collector. A waste conveying device is installed between the air preheater and the pulverized coal pipeline. The waste conveying device includes a powder bin 2 and a powder conveying belt 1 arranged at the entrance of the powder bin 2. The screw powder feeder 3 at the outlet of the warehouse. The screw powder feeder 3 of the present invention is adjusted by a frequency conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com