Wire bundle fixing bracket

A wire harness fixing and wire harness fixing device technology, applied in the field of auto parts, can solve the problems that multiple wire harnesses cannot be combined and installed separately, and achieve the effect of avoiding the occupied space and reducing the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

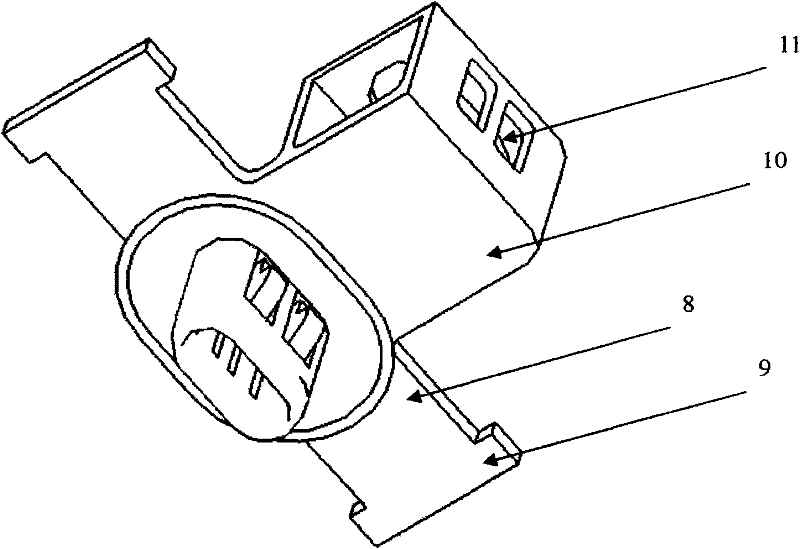

[0042] Attached below Figure 3-6 The present invention will be specifically described.

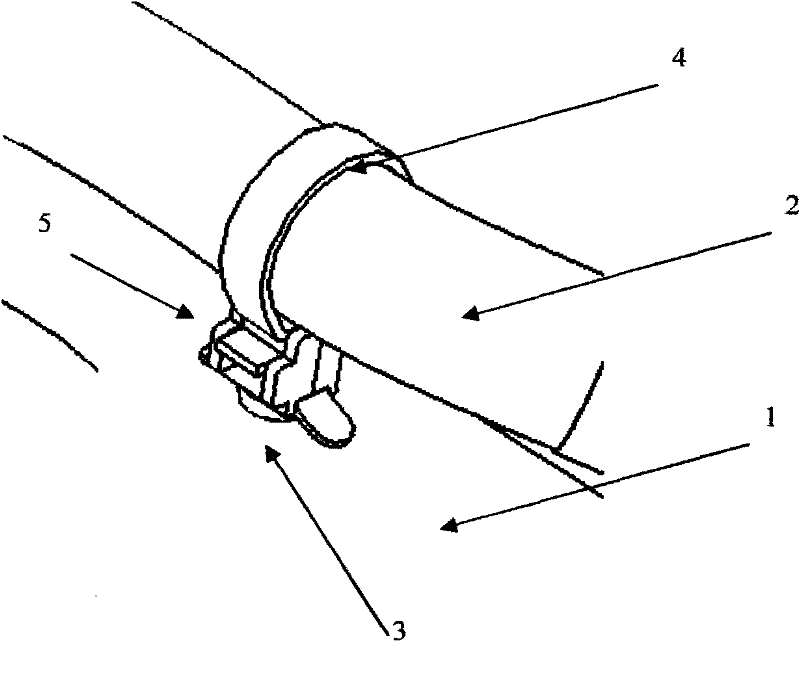

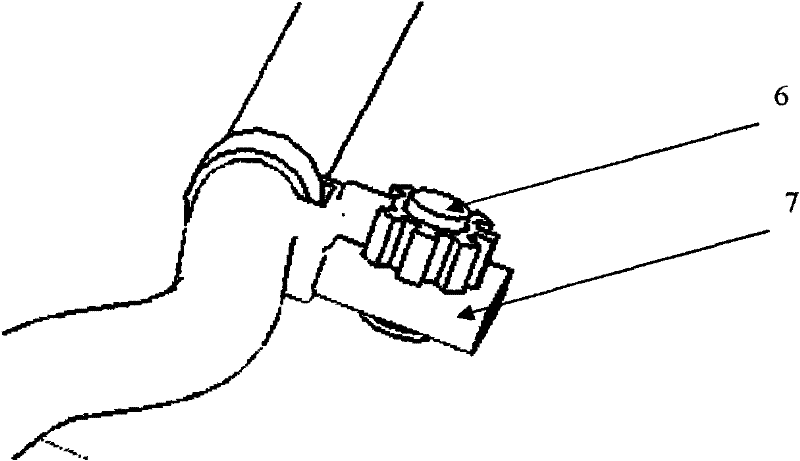

[0043] Such as Figure 3-6 As shown, the wire harness fixing bracket of the present invention includes: a wire harness fixing device, a clamping structure and a protruding structure, wherein the clamping structure is located under the wire harness fixing device, and the protruding structure protrudes from the side of the wire harness fixing device, and is a staple or The cable tie provides an anchor point.

[0044] The wire harness fixing device includes a binding flat plate 8, and the wire harness is bound to the flat plate 8 by using a binding strap. There is a binding belt locking structure 9 at the end of the flat plate 8, which is used to ensure reliable fastening of the wire harness and the staple. The clamping structure includes a sheet metal clamping portion 15 with an oblong cross section, a crimping sheet metal skirt 14 and a buckle 17 positioned on the side of the clamping p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com