Novel structural high-pressure balance valve

A new type of structure and balance valve technology, applied in the field of balance valves, can solve the problems of increased material cost and machining cutting amount, corrosion resistance, poor high temperature resistance, difficulty in assembly and maintenance of large valves, etc., to achieve superior performance and low friction coefficient , The valve is compact and beautiful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

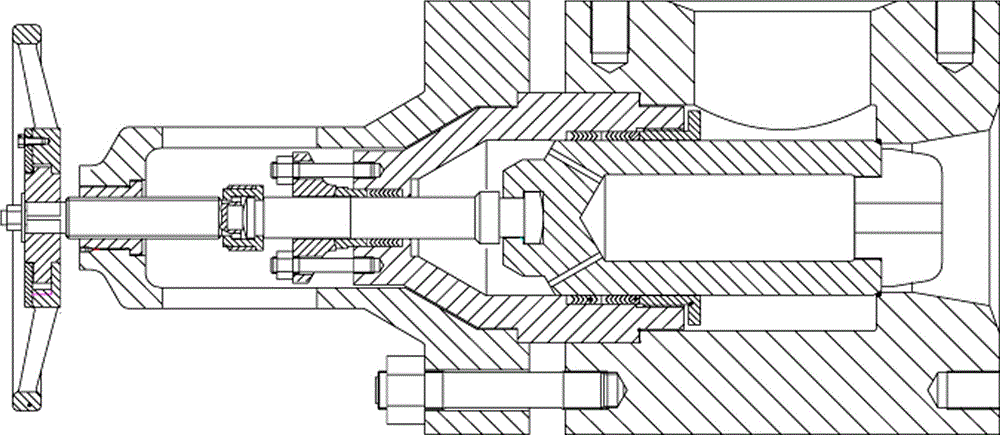

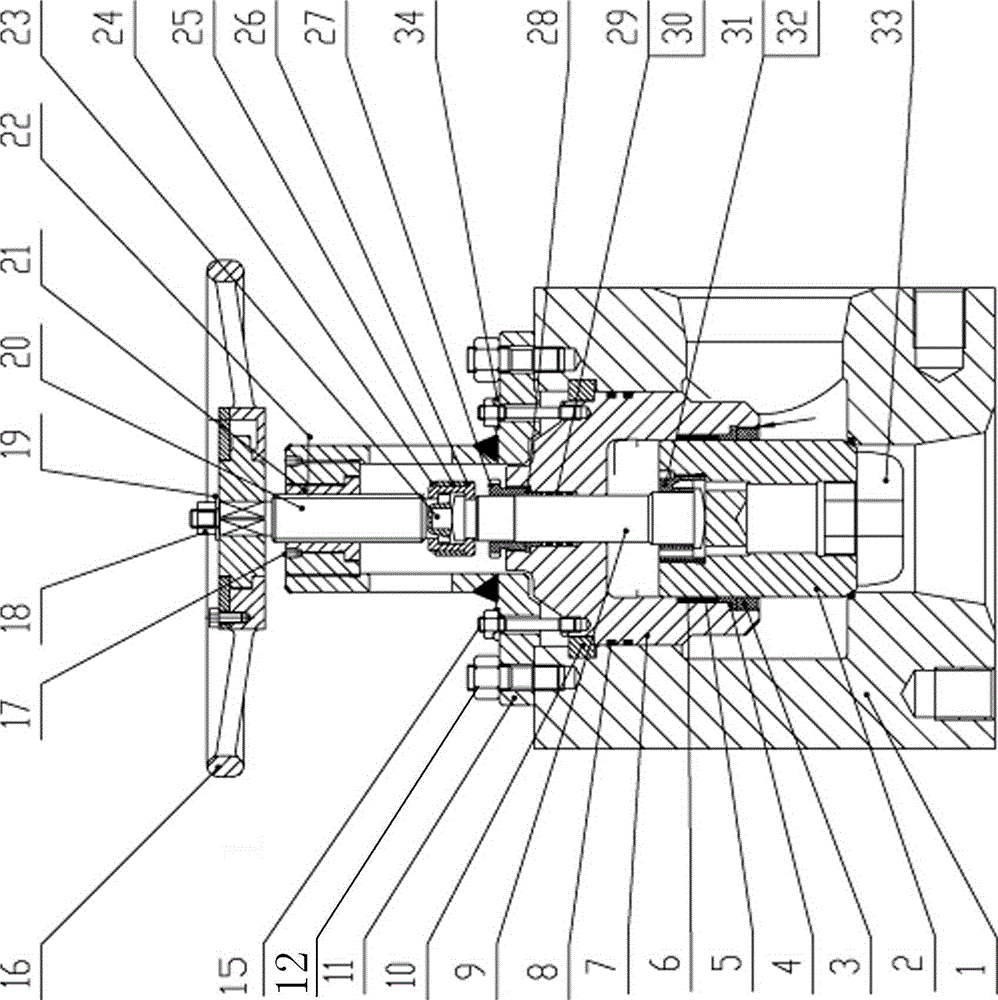

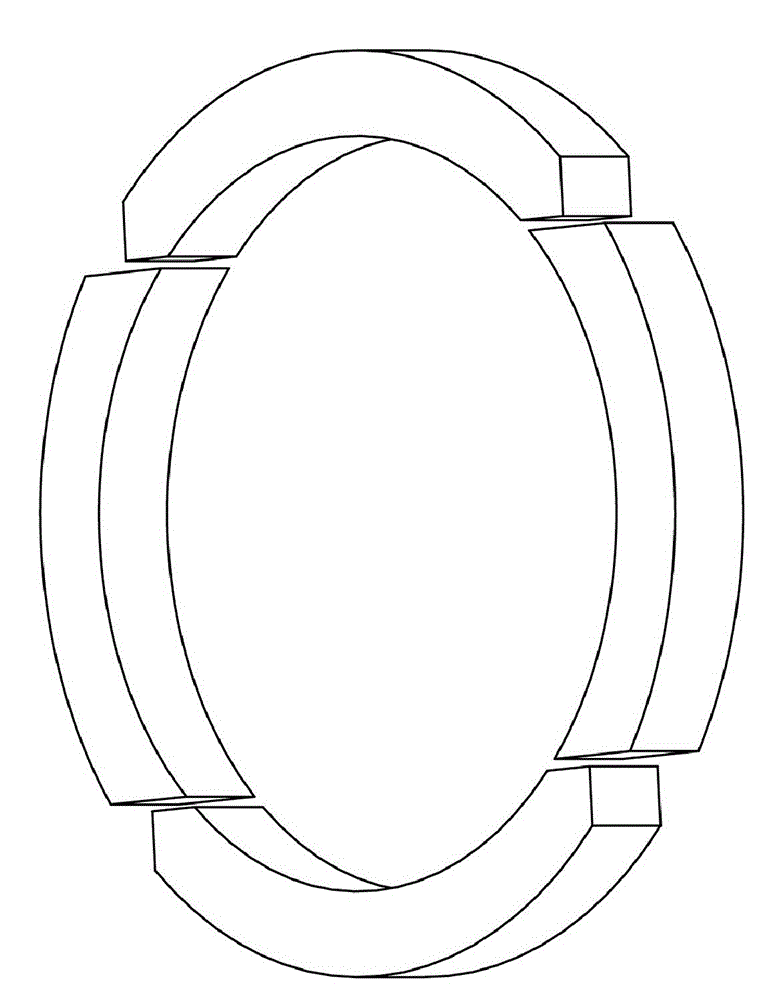

[0026] Depend on Figures 1 to 10 It can be seen that the present invention includes a valve body 1, a stuffing box assembly, a valve stem assembly, a bracket assembly, a handwheel assembly, a four-way ring 10 and a split jacket 26, wherein:

[0027] The inside of the valve body 1 is a cavity, with holes on its upper, lower, and side surfaces. The fluid enters the valve body 1 through the bottom hole of the valve body 1 and flows out through the measuring hole; The assembly seals the high-pressure medium in the valve body 1 and fixes the valve stem assembly; the valve stem assembly is interspersed in the stuffing box assembly, and the valve stem assembly moves up and down to realize the opening and closing of the measuring hole of the valve body 1; the valve body 1 and the stuffing box assembly The upper part of the bracket assembly is provided with a bracket assembly, the bracket assembly is fixed on the valve body 1, and is auxiliary connected to the stuffing box assembly; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com