Boiler over-fire air adjusting method based on momentum moment

An adjustment method, a technology of burnout air, applied in the combustion method, combustion air/fuel supply, adjustment of air supply and other directions, can solve problems such as adjustment of boiler burnout air, and achieve elimination of residual rotation, convenient use, and flue gas distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

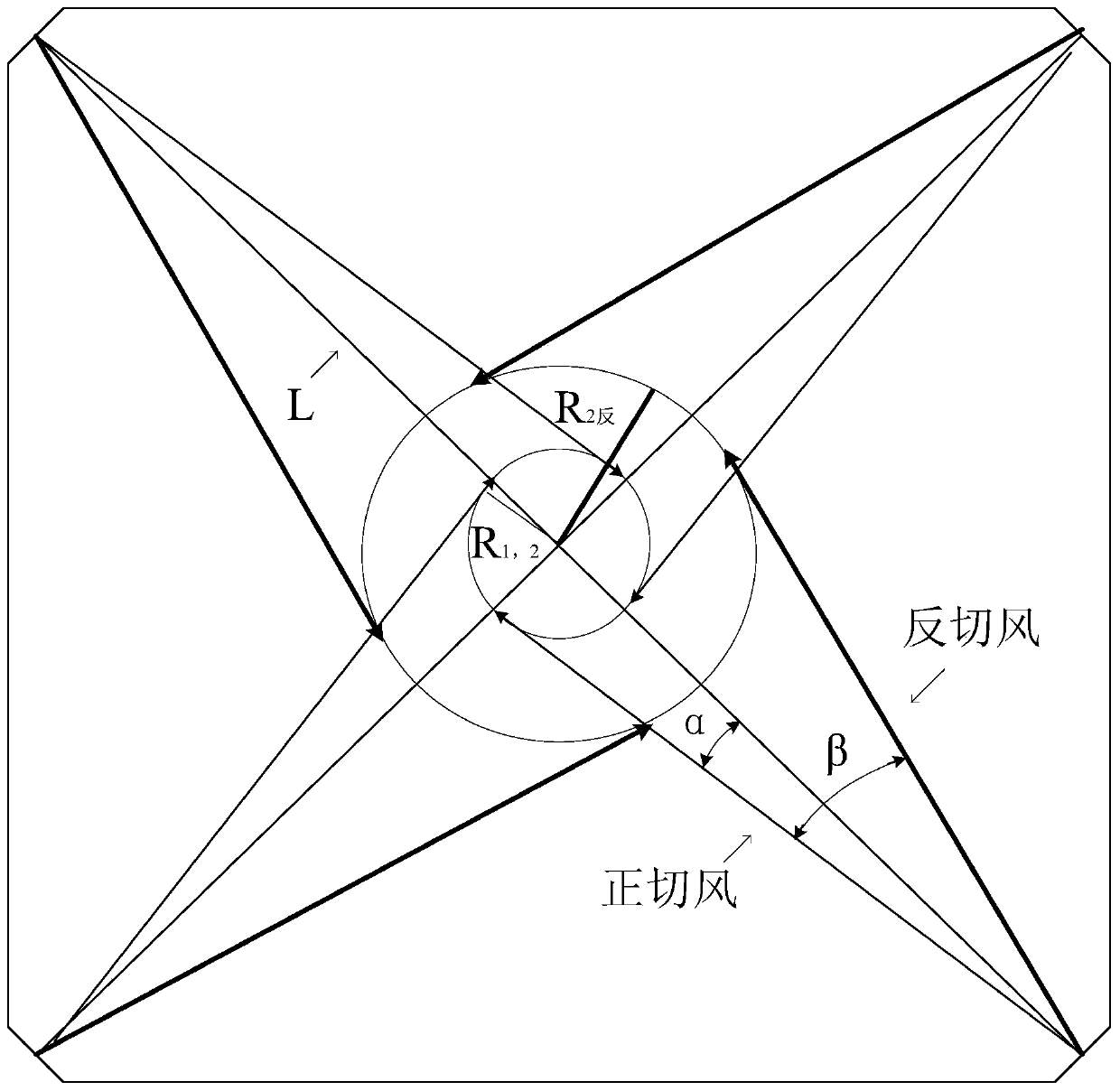

[0044] A method for adjusting boiler burn-out air based on power moment, including a four-corner tangential combustion boiler, the combustion area forms a clockwise or counterclockwise combustion tangent circle, and in order to eliminate residual rotation in burn-out air, a counterclockwise or clockwise rotation is formed. the inverse circle of

[0045] The sum of the momentum moments of the burners with opposite rotation directions in the main combustion zone is the anti-tangential wind momentum moment; the sum of the momentum moments of the burners with the main combustion zone rotating in the same direction is the tangential wind momentum moment;

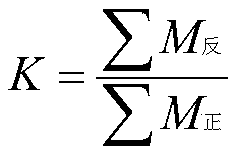

[0046] The sum of the inverse tangential wind momentum and the sum of the tangential wind momentum are compared:

[0047]

[0048] In the formula, M 反 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com