Combustion technology of low nitrogen oxide

A combustion method and technology for pulverized coal boilers, which are applied in combustion methods, combustion using lump fuel and powder fuel, combustion using liquid fuel and powder fuel, etc., can solve the problem of not considering the control of NOX, etc., to avoid slagging Corrosion problem, low-load stable combustion, and NOx reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

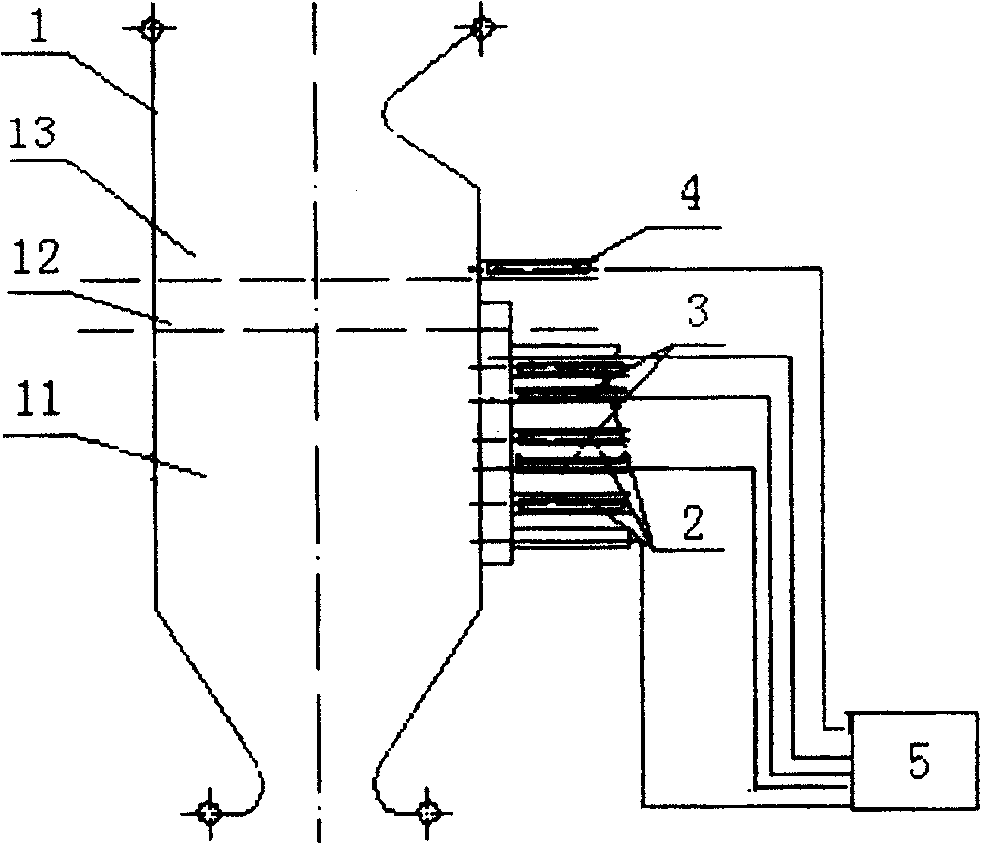

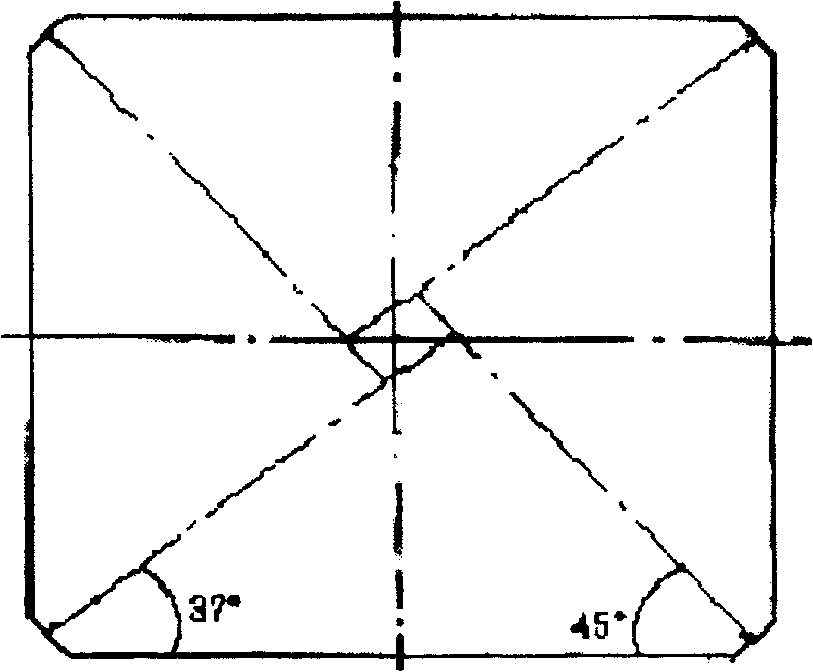

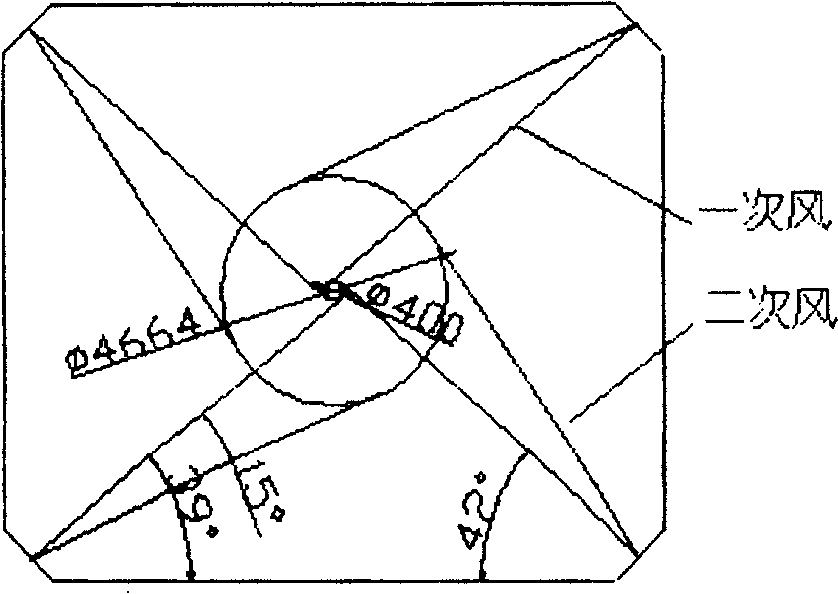

[0023] The low NO of the pulverized coal boiler provided by the invention x The schematic diagram of the combustion method is shown in figure 1 shown. It is composed of furnace 1, burner 2 and tuyere 3, and there are low NO in the four corners of furnace 1 x Burner LNB2 and tuyere 3, furnace 1 is divided into three areas from bottom to top: main combustion zone 11, reduction zone 12 and burnout zone 13, the four corners of the main combustion zone 11 furnace are provided with burners for feeding pulverized coal airflow in layers 2. Schematic diagram of boiler tangential combustion figure 2 As shown, the tuyere 3 for secondary air is set above and below each layer of burners 2, and the horizontal layout of the secondary air is shown in image 3 As shown, on the four corners of the furnace in the burnout area 13, only the tuyere 4 for feeding the burnout air is provided, and the air volume of about 40% of the secondary air is led to the top of the whole set of burners 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com