Over fire air nozzle structure

An exhaust air and nozzle technology, applied in the direction of using a variety of fuel combustion, combustion methods, combustion types, etc., can solve the problems of large smoke temperature deviation, large steam temperature deviation, high CO concentration at the air preheater outlet, and reduce smoke The effect of temperature deviation, strong penetration and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the application according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. .

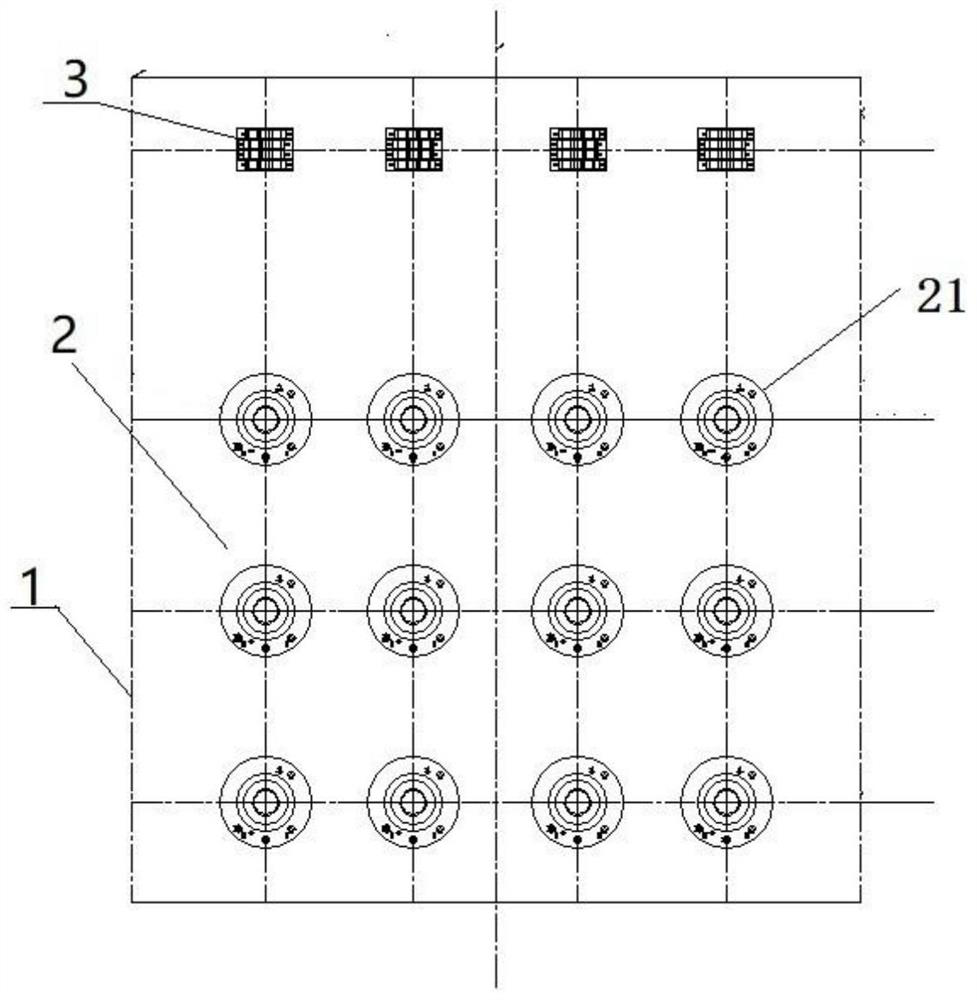

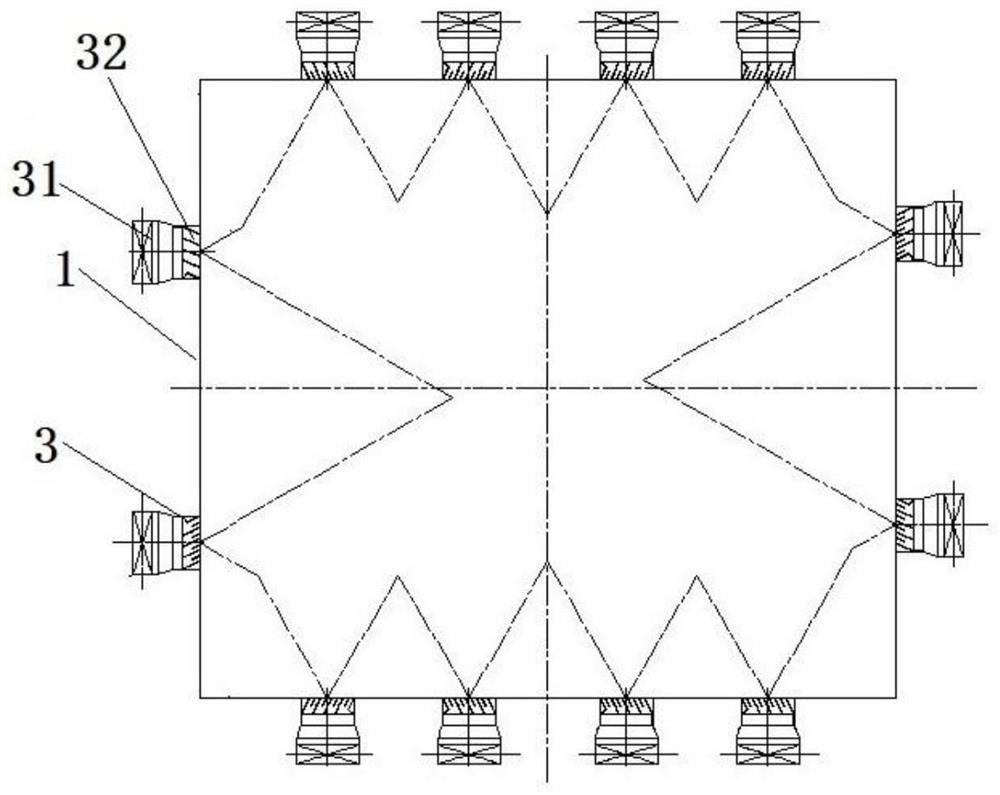

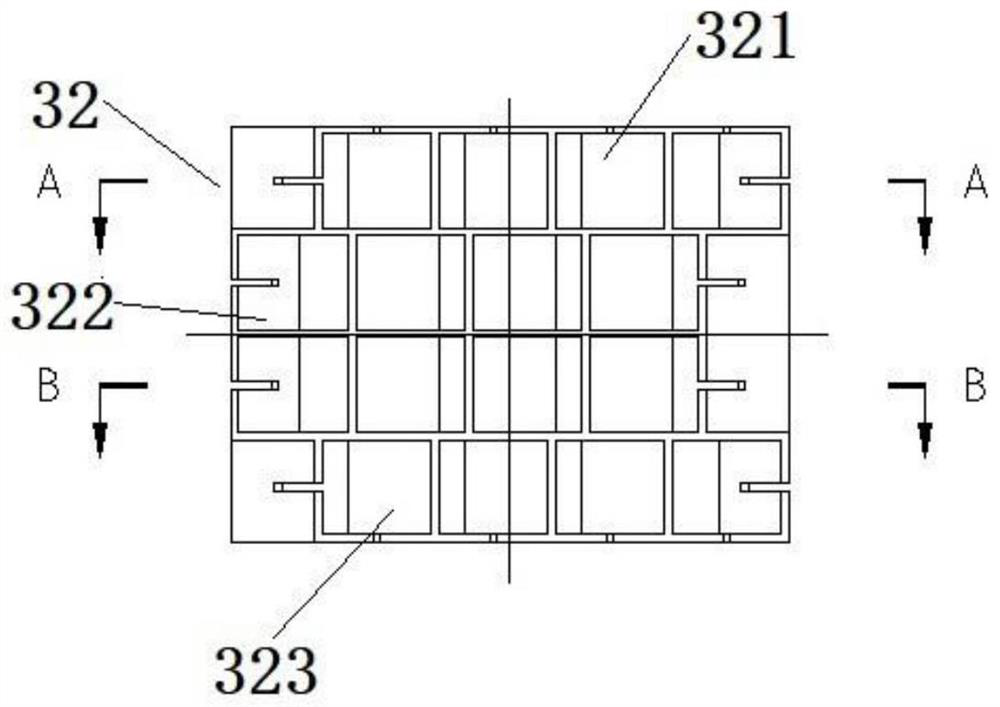

[0030] Such as Figure 1 to Figure 6 As shown, an embodiment of the present invention proposes an overfire air nozzle structure, which includes: a boiler body 1 , a burner 2 in the main combustion zone and a plurality of separate overfire air nozzles 3 .

[0031] Such as figure 1 As shown, the main combustion area burner 2 includes a plurality of pulverized coal burners 21, and the plurality of pulverized coal burners 21 are installed on the front and rear walls of the boiler body 1, and the plurality of pulverized coal burners 21 The primary air is straight air, and a plurality of pulverized coal burners 21 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com