Hexagonal or octagonal tangential arrangement of fuel-oil or fuel-gas single-fireball direct-flow combustors

An octagonal tangent and burner technology, which is applied to the combustion of block fuel and liquid fuel, the combustion of block fuel and gaseous fuel, and the combustion of block fuel and powder fuel, which can solve the problem of low boiler manufacturing Cost and other issues, to achieve good air supply conditions, increase convection and radiation heat transfer, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

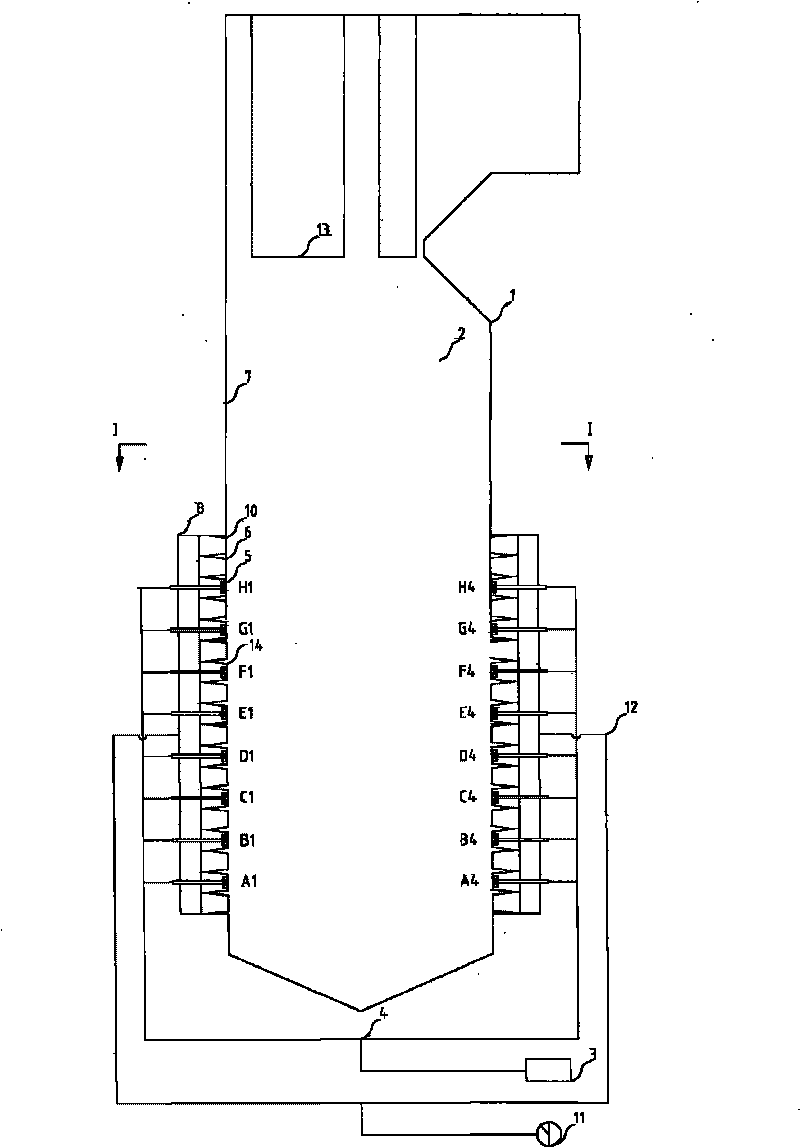

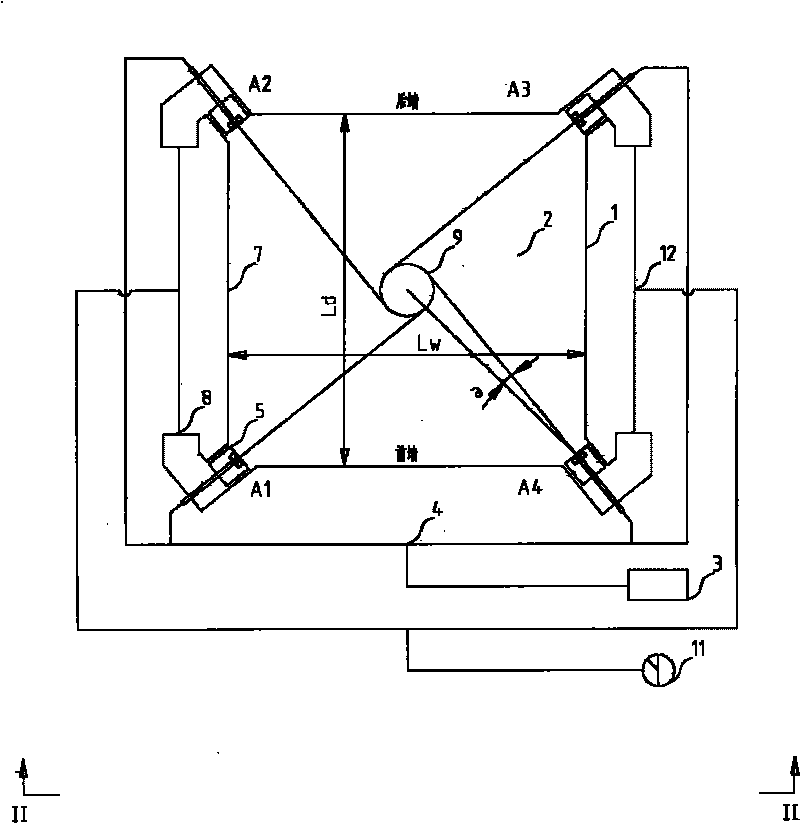

[0029] combine image 3 and Figure 4 To describe this embodiment, Figure 4 for image 3 I-I sectional view, image 3 for Figure 4 Section view of II-II.

[0030] The present invention provides a hexagonal or octagonal tangential arrangement of a single fireball direct-flow burner for fuel or gas, including a boiler body 1, a furnace 2, a fuel or gas operating station 3 in front of the furnace, a fuel or gas pipeline 4, and an oil gun or air gun 5 , Fuel air nozzle 14, secondary air nozzle 6, overfire air nozzle 10 and furnace outlet heat exchange screen 13. Each boiler 1 is equipped with a set of fuel oil or gas operation station 3 in front of the furnace. The furnace 2 is composed of four water-cooled walls 7. Two sets of burners 8 are arranged on each water-cooled wall 7 of the furnace 2. There are eight sets of burners 8 in total. The two sets of burners on the front wall are respectively a set of burners 8 and 8. Group of burners 8, the two groups of burners on t...

Embodiment 2

[0036] combine Figure 5 and Figure 6 To describe this embodiment, Figure 6 for Figure 5 I-I sectional view, Figure 5 for Figure 6 Section view of II-II.

[0037] The difference between this embodiment and Embodiment 1 is that two sets of burners 8 are respectively arranged on the water-cooled walls 7 of the front and rear walls of the furnace 2, and one set of burners 8 are respectively arranged on the left and right water-cooled walls 7 of the furnace 2. There are six burners in total. Group of burners, two groups of burners on the front wall are 1 group of burners 8, 6 groups of burners 8, one group of burners on the left wall are 2 groups of burners 8, and two groups of burners on the back wall are 3 groups of burners respectively 8, 4 sets of burners 8, one set of burners on the right wall is 5 sets of burners 8. Each group of burners 8 is arranged with four oil guns or air guns 5 at intervals along the vertical direction. For example, one group of burners 8 in...

Embodiment 3

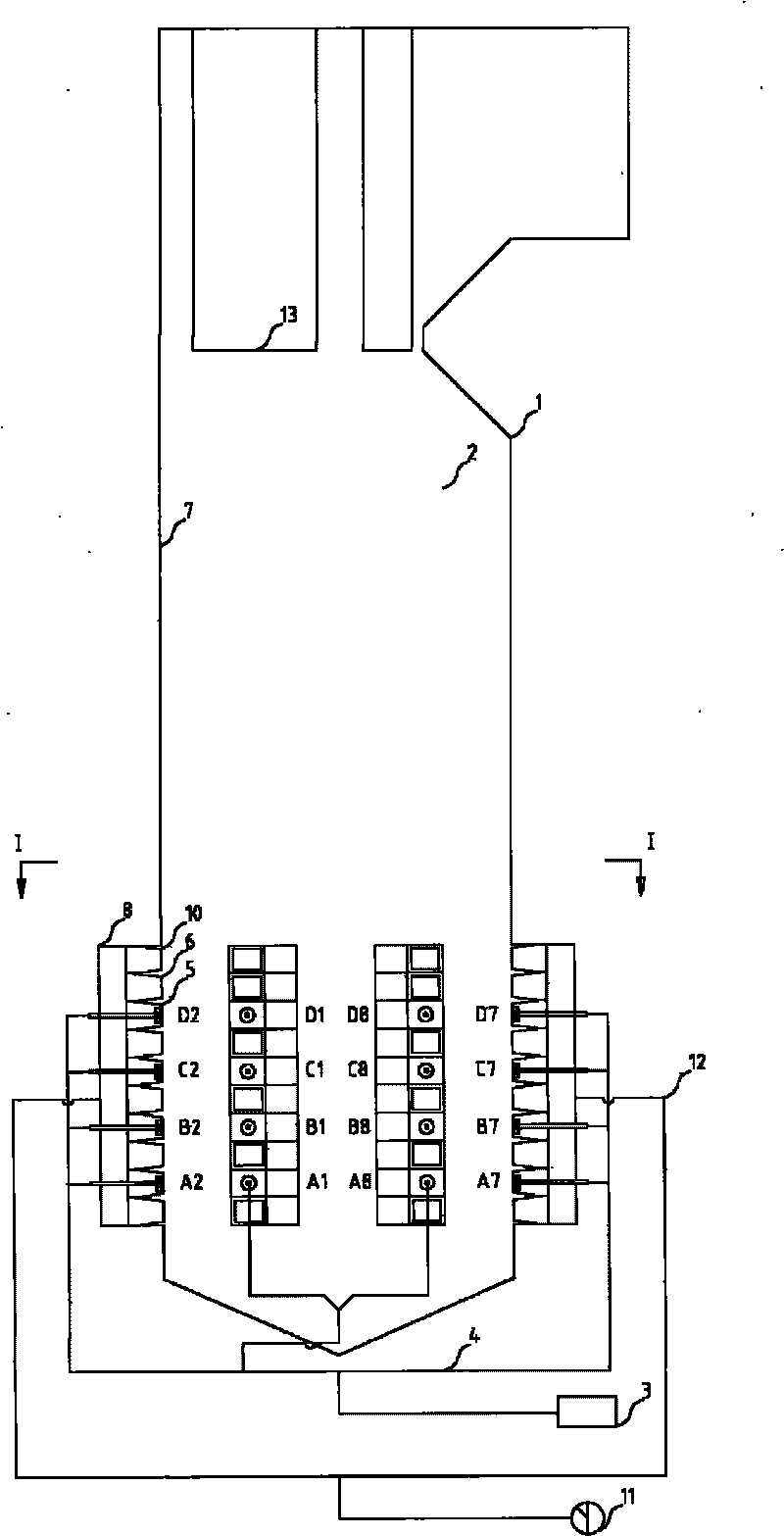

[0041] combine Figure 7 and Figure 8 To describe this embodiment, Figure 8 for Figure 7 I-I sectional view, Figure 7 for Figure 8 Section view of II-II.

[0042] The difference between this embodiment and Embodiment 1 is that a group of burners 8 are respectively arranged on the four corners of the furnace 2, and a group of burners 8 are respectively arranged on the four water-cooled walls 7 of the furnace 2, and there are eight groups of burners in total. The four groups of burners 8 on the four corners are 1 group of burners 8, 3 groups of burners 8, 5 groups of burners 8, 7 groups of burners 8, and the numbers of four groups of burners 8 on the four walls are 2 groups Burners 8, 4 sets of burners 8, 6 sets of burners 8, 8 sets of burners 8. Each group of burners 8 is arranged with four oil guns or air guns 5 at intervals along the vertical direction. For example, one group of burners 8 includes four oil guns or air guns 5, which are respectively the first oil gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com