Method for growing rhenium disulfide nanometer sheets on silicon substrate of non-oxidation layer

A rhenium disulfide and silicon substrate technology, applied in chemical instruments and methods, inorganic chemistry, rhenium compounds, etc., can solve problems such as morphology, structural damage, troubles, etc., and achieve the effect of overcoming direct growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

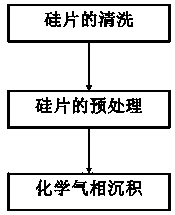

[0036] 1. A method for growing rhenium disulfide nanosheets on a silicon substrate without an oxide layer, which is prepared by chemical vapor deposition, and the preparation process is as follows figure 1 shown.

[0037] Materials used are: 500 mg sublimated sulfur (aladin, 99.99%), 1.5 mg ReO 3(aladin, 99.9%); hydrofluoric acid (Tianjin Damao Chemical Reagent Factory), three-temperature zone tube furnace (Hefei Kejing Material Technology Co., Ltd., OTF-1200X-Ⅲ), argon (purity 99.999%) .

[0038] Concrete preparation process is as follows:

[0039] (1) Cleaning the silicon substrate: Cut a commercially available circular silicon wafer without an oxide layer into small pieces of 2.5 cm*2.5 cm, and then ultrasonically clean them in the order of acetone, ethanol, and deionized water for 10 min each, with an ultrasonic power of 180 W. Frequency 40KHz.

[0040] (2) Pretreatment of silicon substrate: soak the cleaned silicon wafer in a certain concentration of hydrofluoric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com