A method for overcoming the relative slippage between the slab specimen and the bar in the hopkinson tension bar test

A technology of test pieces and strips, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of Hopkinson tie rods and fixtures slipping, uneven deformation, time-consuming, etc., to achieve No gap contact, not easy to local deformation, and the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0020] The method for overcoming the relative slipping of the lath test piece and the rod in the Hopkinson pull bar test of the embodiment may further comprise the steps:

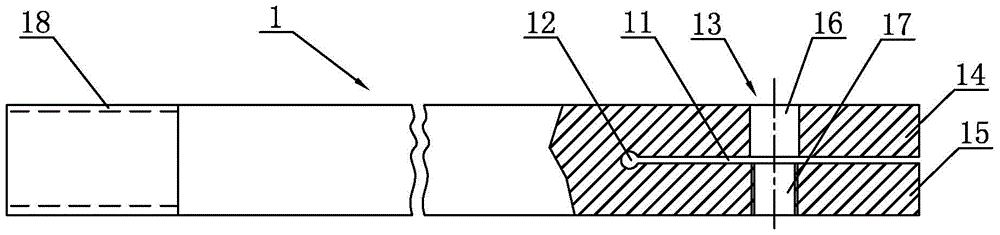

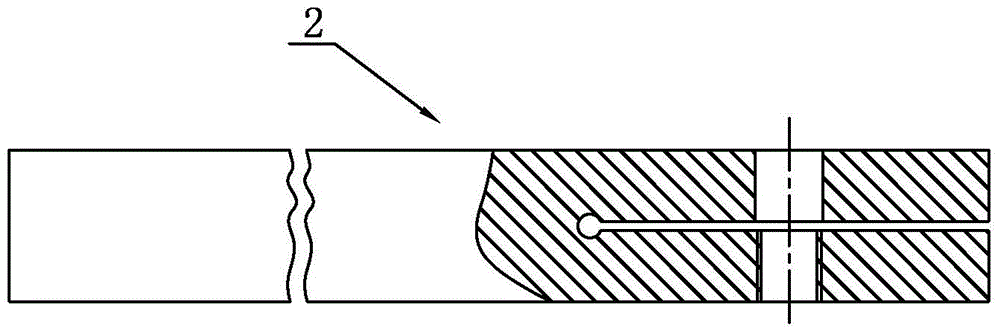

[0021] 1) Prepare cylindrical semi-finished incident rods, semi-finished transmission rods and slab test pieces of appropriate size with an outer diameter of Ф19mm;

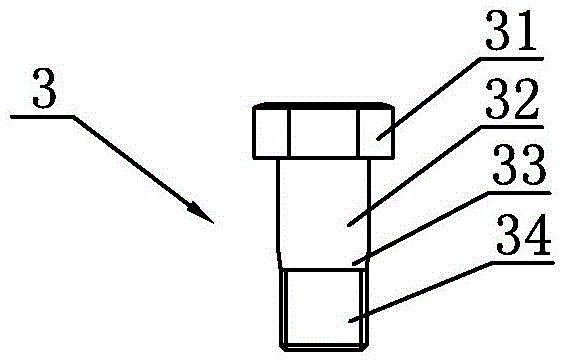

[0022] 2) Process a radial through groove 11 along the radial direction at one end of the semi-finished product of the incident rod. The depth of the radial through groove 11 is 50 mm and the height is 1.2 mm. A radial through hole 12 connected with the radial through groove 11, the diameter of the radial through hole 12 is Ф3mm, through the radial through groove 11 and the radial through hole 12, one end of the incident rod semi-finished product is equally divided into The first pressing part 14 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com