Concrete structure through-wall pipe construction reserving structure and construction method

A technology for concrete structures and wall-pipes, which is applied to walls, building components, building structures, etc. It can solve the problems of difficult to deal with leakage points, leakage, and inability to find leakage, so as to ensure seamless contact and prevent leakage. leaky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the addition.

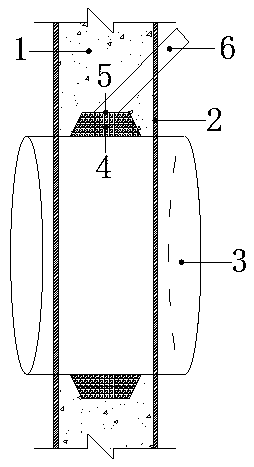

[0022] The construction reserved structure of the concrete structure wall pipe of the present invention includes primary structure wall concrete 1, primary structure wall side formwork 2, wall reserved hole formwork 3, trapezoidal foam board 4, plastic tape 5, and secondary grouting pipe φ75PVC Tube 6. A trapezoidal foam board 4 is installed in the middle section of the formwork 3 with reserved holes in the wall, and the primary structural sideform 2 passes through both ends of the formwork with reserved holes in the wall.

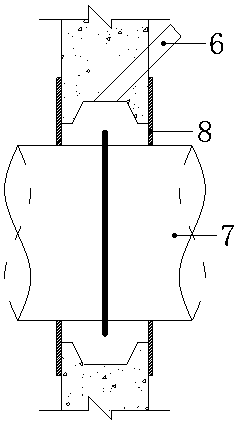

[0023] The trapezoidal foam board of the present invention is processed by polyethylene foam board, and the foam board makes the reserved hole wall after molding form a concave structure, and the trapezoidal foam board adopts round nails 7 to be fixed on the wall body reserved hole mold, and the number of round nails is less than The stability of the foam boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com