Ethylene quenching apparatus and compressing energy-saving technique

A quenching and ethylene technology, applied in ethylene production, petroleum industry, cracking, etc., can solve the problems of low energy utilization efficiency and low energy recovery efficiency of the quenching system, and achieve the effect of saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

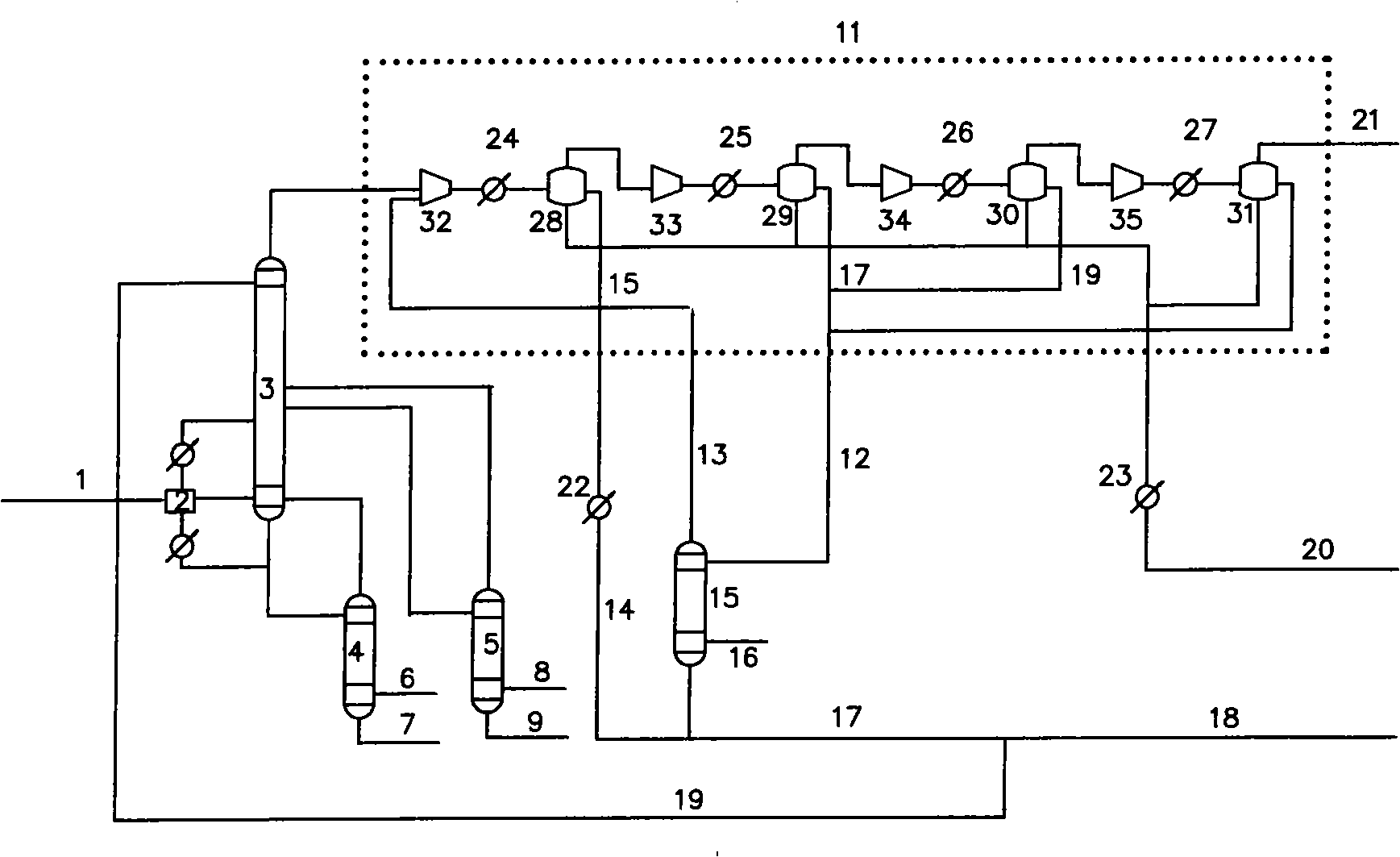

[0023] The present invention will be specifically described below in conjunction with the drawings and embodiments, but the present invention is not limited to the drawings and embodiments.

[0024] The method of the invention is used in the fractionation compression system of an ethylene quenching device. Process such as image 3 As shown, the cracked gas 1 from the waste heat boiler directly enters the multi-stage compression separation compression system 11 after being fractionated and cooled by the quencher 2 and the gasoline fractionation tower 3 . The multi-stage compression separation system 11 is composed of four-stage compressors (32, 33, 34, 35), heat exchangers (24, 25, 26, 27) and oil-water separation tanks (28, 29, 30, 31). After multi-stage compression, the cracked gas 21 enters the subsequent separation process. In the multi-stage compression separation system, the temperature of the cracked gas is raised after being compressed, and then the inter-stage heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com