Gas-mass-flow up-down-stream temperature distribution secondary differential measuring method, sensor and flowmeter

A technology of gas mass flow and temperature distribution, applied in the direction of mass flow measurement device, etc., can solve the problems of easy to cause errors, low measurement accuracy, insensitive low-speed section, etc., to eliminate errors, low power consumption, and improve flow test. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

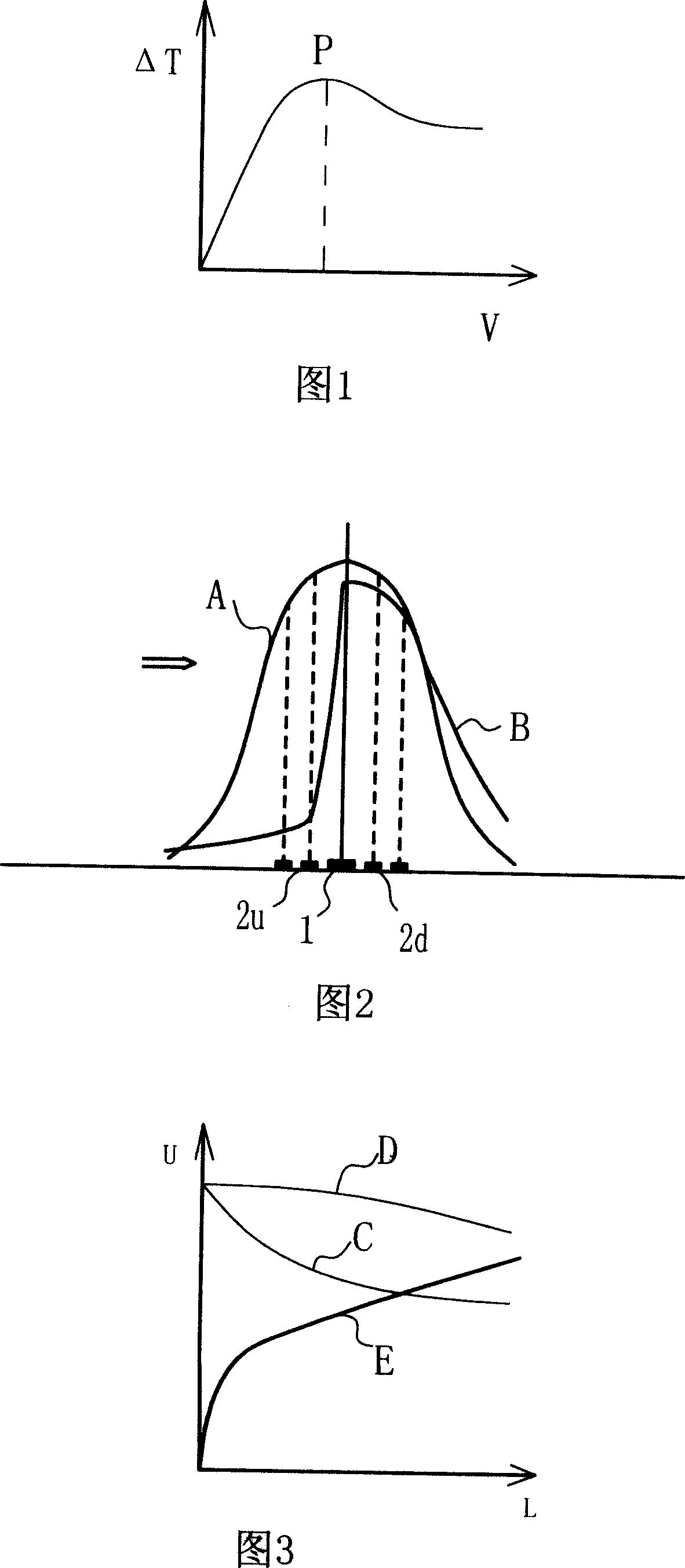

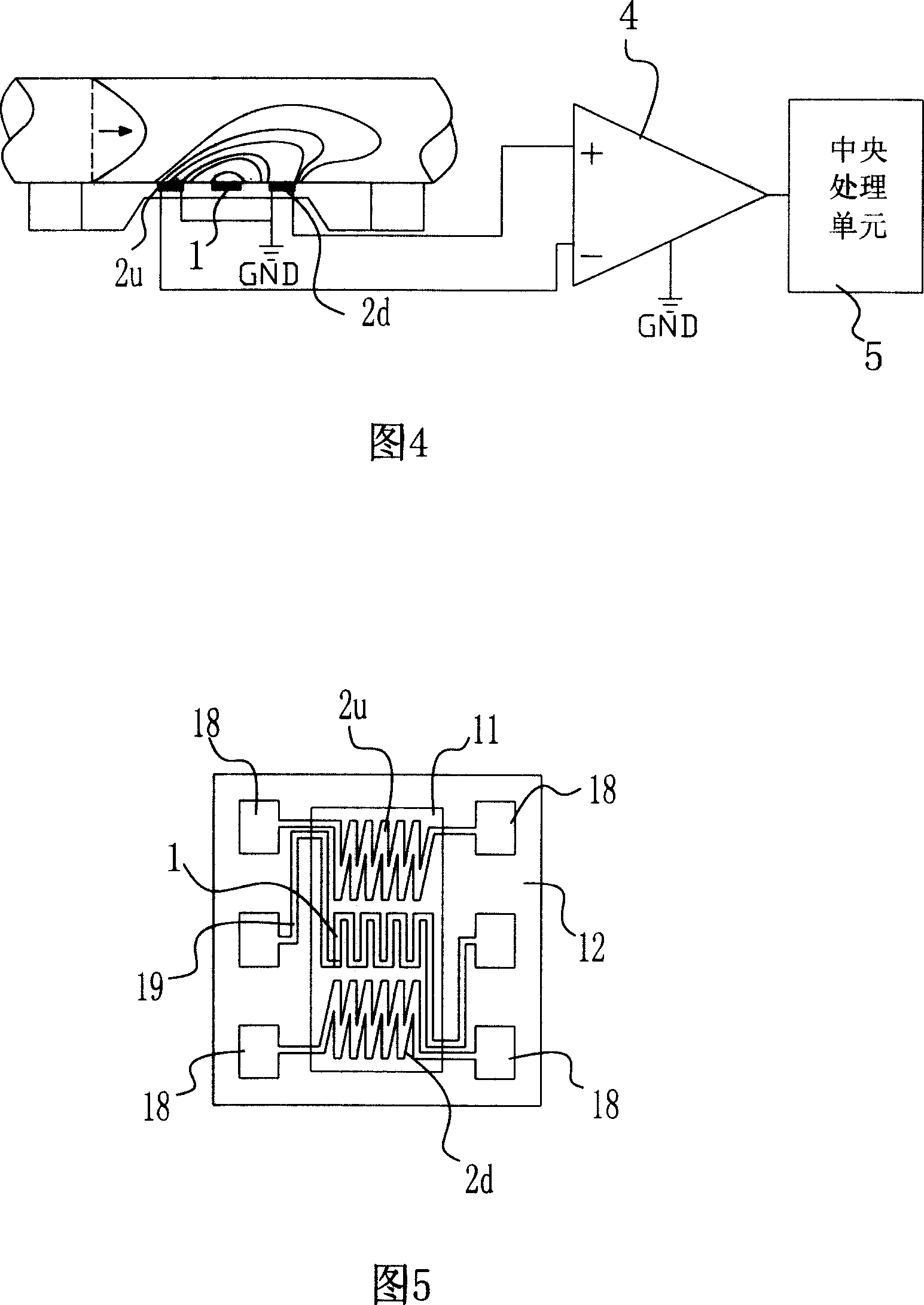

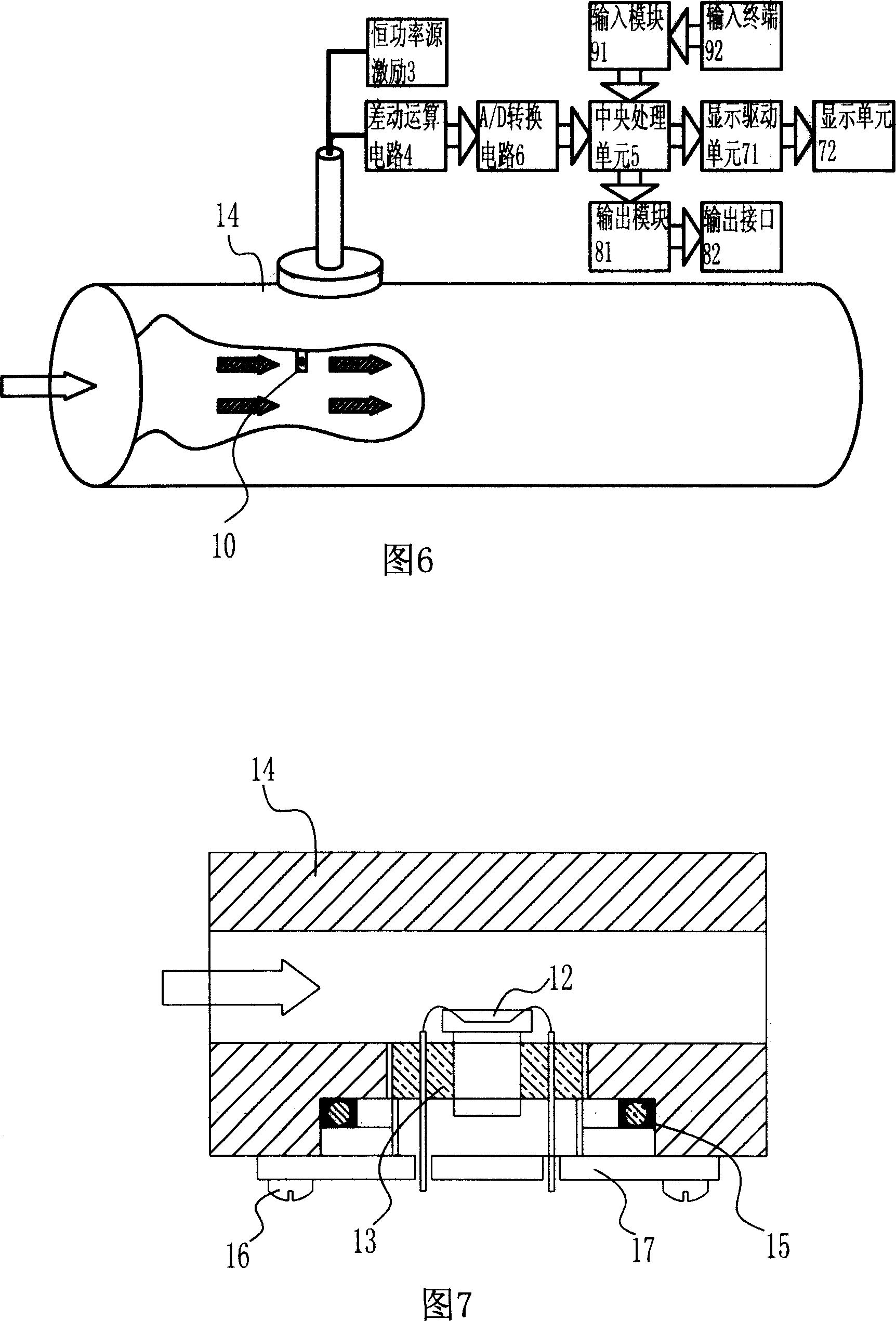

[0055] The secondary differential measurement method of the upstream and downstream temperature distribution of the gas mass flow is characterized in that: a. A constant power source excitation 3 is applied to the heating element 1 of the sensor, and the temperature detection elements symmetrically arranged on both sides of the heating element are respectively measured The temperature distribution of the upstream and downstream of the heating element in the state of no air flow; b. When the gas flows through the sensor, the upstream temperature detection element 2u measures the temperature distribution change in the area and outputs an upstream temperature difference signal, and the downstream temperature detection element 2d measures the temperature distribution in the area The regional temperature distribution changes and the output generates a downstream temperature difference signal; c. Subtract the downstream temperature difference signal from the upstream temperature diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com