System for rotational flow dust removal and recovery of blast furnace roof raw gas and recovering method of blast furnace roof raw gas

A recovery system and furnace top gas technology, applied in the direction of dust collector, etc., can solve the problems of bag filter wear, easy dust deposition, affecting economic benefits, etc., to achieve the effect of improving service life, good dust removal effect and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

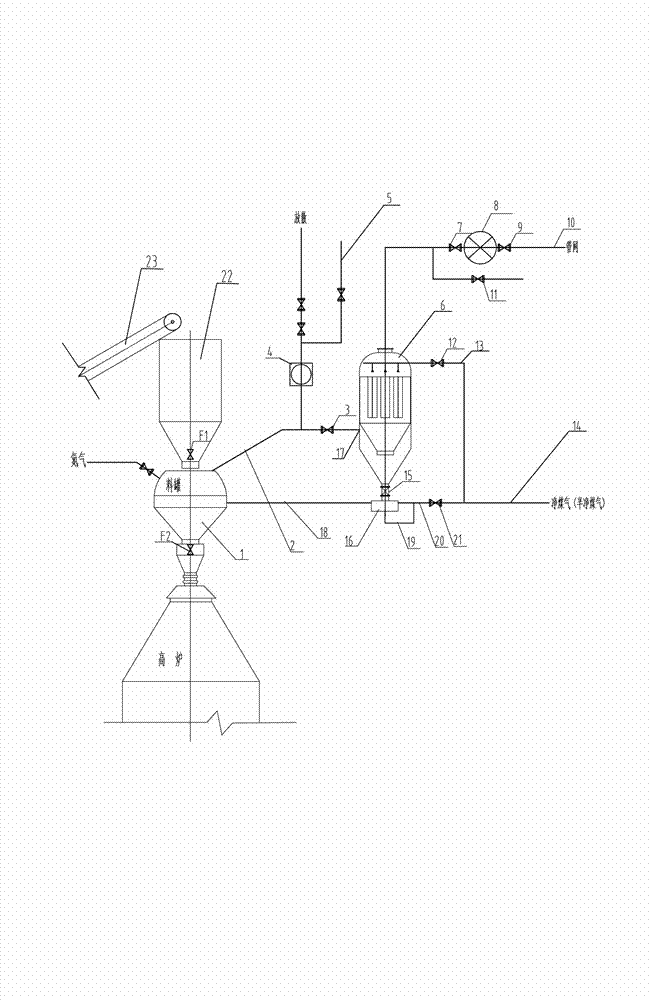

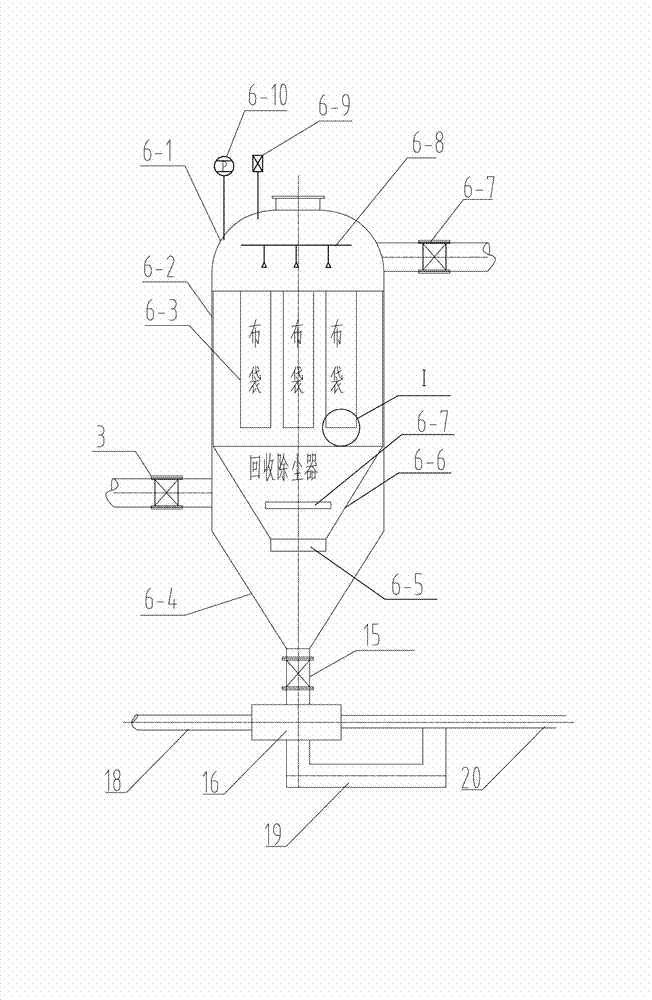

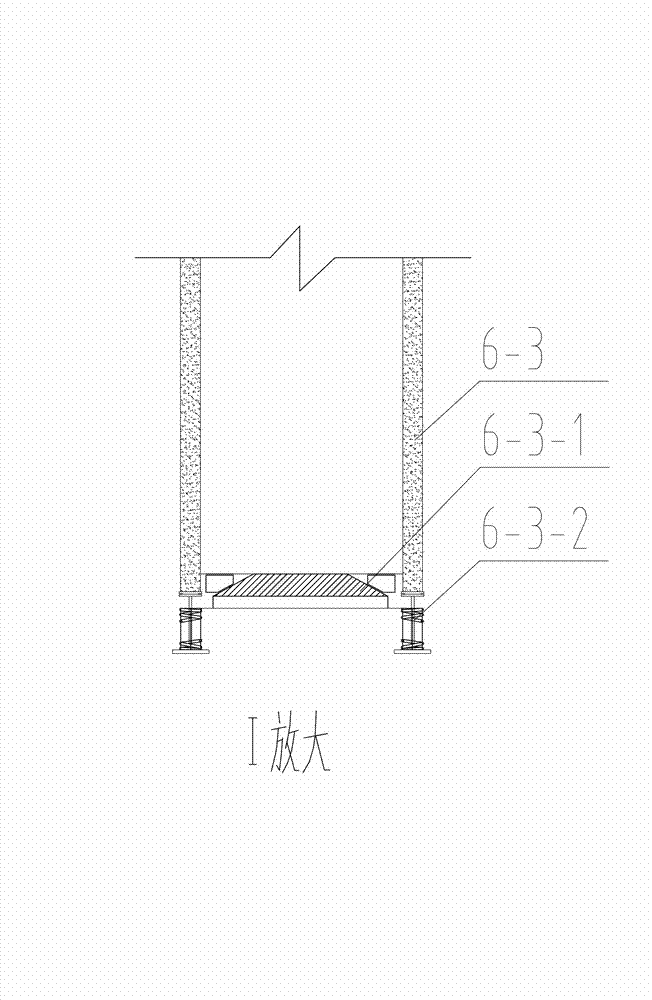

[0026] Such as figure 1 , figure 2 , image 3As shown, the blast furnace top waste gas cyclone dust removal recovery system of the present invention includes a blast furnace top waste gas output pipeline 2 connected to a blast furnace top tank 1, a blast furnace top waste gas shut-off valve 3, a blast furnace gas bag filter 6, The clean gas pipe network 10 and the clean gas cut-off valve connected with the blast furnace gas bag filter 6, the blast furnace gas bag filter 6 consists of an upper semicircular limelight shell 6-1, a middle cylindrical shell 6- 2 and the outer casing composed of the lower conical casing 6-4, the clean gas outlet connected to the clean gas pipe network 10, the pressure sensor 6-10 and the oxygen meter arranged on the upper semicircular air head casing 6-1 6-9, the dust removal bag group 6-3 arranged in the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com