Gas sorbents on the basis of intermetallic compounds and a method for producing the same

a technology of intermetallic compounds and gas sorbents, which is applied in the field of gas sorbents, can solve the problems of inapplicability to alkaline-earth metals, not a breakthrough, and difficult to achieve high chemical pumping rates, and achieve the effect of high gas permeability and high surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

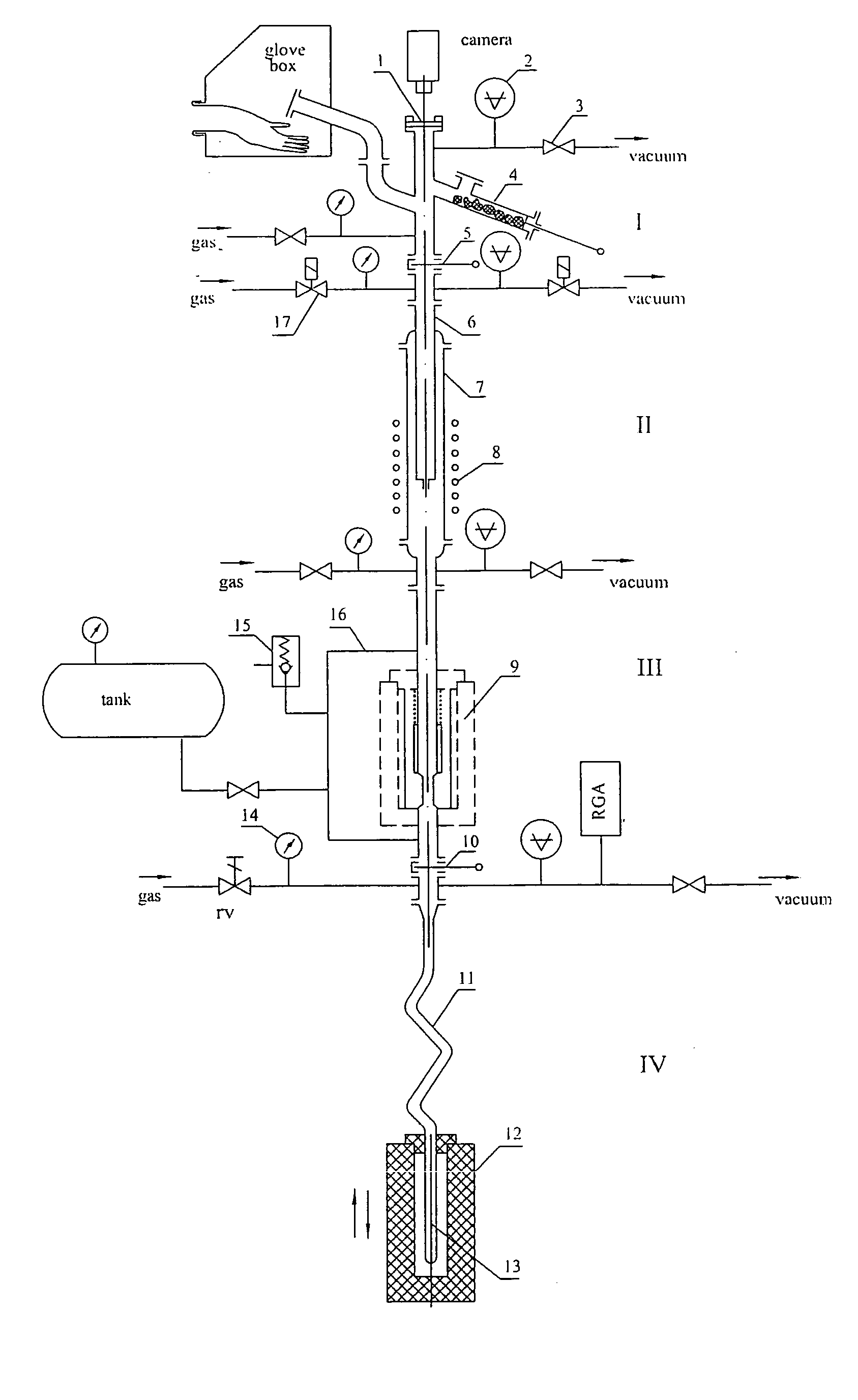

[0074] The given method allows the preparation of an alloy c0 from corresponding quantities of elements A and Me directly in the melting compartment II of the process column (FIG. 4). Such a solution guarantees a higher purity of the product than it was allowed by the previous technique of the separate synthesis of a semi-ready product in special equipment with the subsequent transfer of the superactive product to the station for granulation (see WO 2004 / 082873).

[0075] According to the new method high purity dendritic pieces of previously distilled Ca or Sr (e.g., 99.98% metals basis, Alfa Aesar) are taken out from a glass ampoule and thrown down from a glove box into crucible 6 (FIG. 4). Further on metal A is melted in an atmosphere of especially pure argon under a pressure around 10 mbar with the help of inductive heating (see coil 8 on FIG. 4), maintaining below the crucible excess pressure, which prevents leaking of liquid metal through a capillary into the flight tube. Then pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com