Device for recovering coal gas in equalizing and relieving process of furnace top of blast furnace

A technology for releasing coal gas and blast furnace, applied in the direction of dust collector, etc., can solve the problems that it is difficult to realize the effective recovery of the uniform pressure release gas and the complete release of the clean coal gas, and the high recovery cost, and achieves low fixed investment and operation and maintenance costs, major economic benefits and high cost. Social benefits, the effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

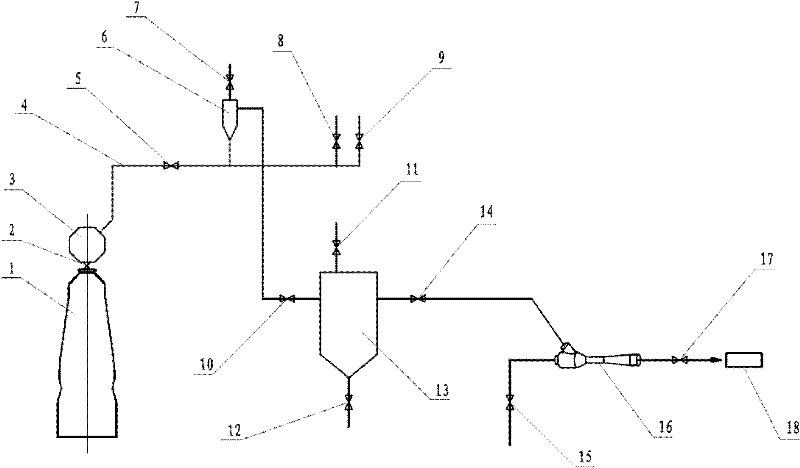

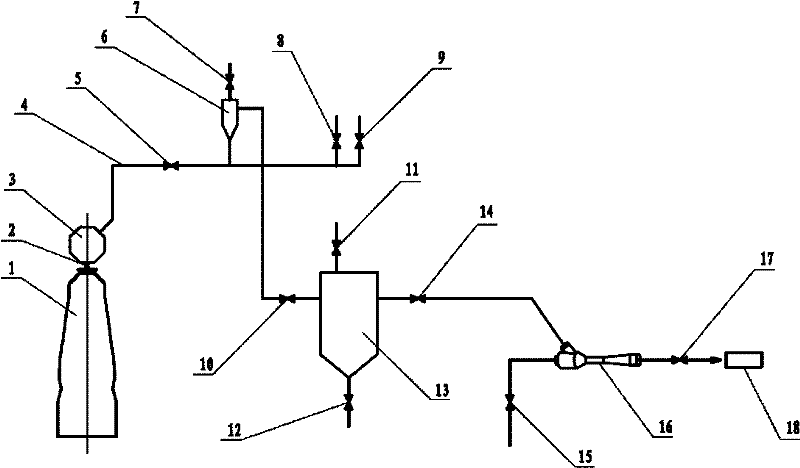

[0021] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] Such as figure 1 As shown, the gas recovery device in the pressure equalization and release process on the top of the blast furnace, the blast furnace body 1 is connected to the weighing tank 3 through the feeding valve 2, and the raw gas released from the weighing tank 3 through the pressure equalization and release pipe 4 enters the cyclone After preliminary dust removal by the dust collector 6, the bag filter 13 connected in series after entering the cyclone dust collector 6 performs fine dust removal to form clean gas. The bag filter device 13 is connected in parallel with the blast furnace top gas bag filter system.

[0023] An ejector 16 is connected to the back of the bag filter 13, so that the clean gas after the fine dust removal by the bag filter 13 enters the clean gas pipe network ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com