Air bag type pressure regulating device for material feeding operation of high-pressure smelting furnace

A pressure regulation and smelting furnace technology, applied in blast furnace details, blast furnace, furnace type and other directions, can solve problems such as large waste, achieve the effect of simplifying the process, solving the problem of air discharge, and eliminating air discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

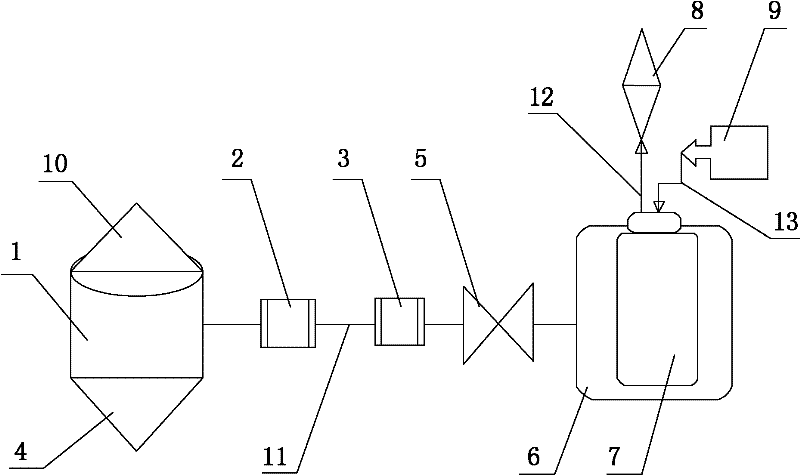

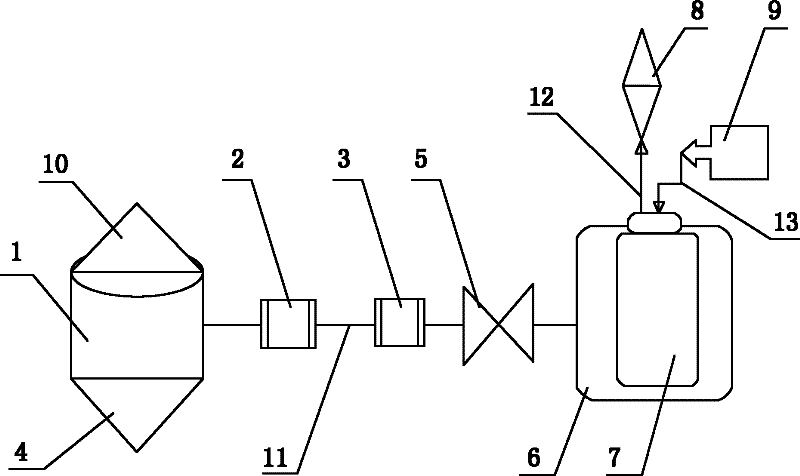

[0013] Such as figure 1 As shown, the air bag-type pressure regulating device used for feeding high-pressure smelting furnace includes universal corrugated compensator 2, axial corrugated compensator 3, pressure regulating cut-off valve 5, pressure balance device 6, air bag 7, nitrogen release valve 8, high pressure Nitrogen shut-off valve 9, pressure balance pipeline 11, nitrogen release pipe 12, nitrogen pipe 13; one end of pressure balance pipeline 11 is connected with the pressure regulating outlet of material tank 1, and the other end of pressure balance pipeline 11 is connected with closed pressure balance device ( or pressure balance tank) 6 are connected, and the pressure balance pipeline 11 is provided with a universal corrugated compensator 2, an axial corrugated compensator 3, and a pressure regulating cut-off valve 5; the airbag 7 is located in the cavity of the pressure balance device 6, and the airbag 7 communicate with one end of the nitrogen release pipe 12 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com