Gas pressure equalizing releasing device for pressure vessel multistage dust removing and using method of device

A technology of pressure vessel and pressure equalizing device, applied in blast furnace parts, furnace, blast furnace details, etc., can solve the problems of high emission pollution, easy blockage, and easy damage to bag filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

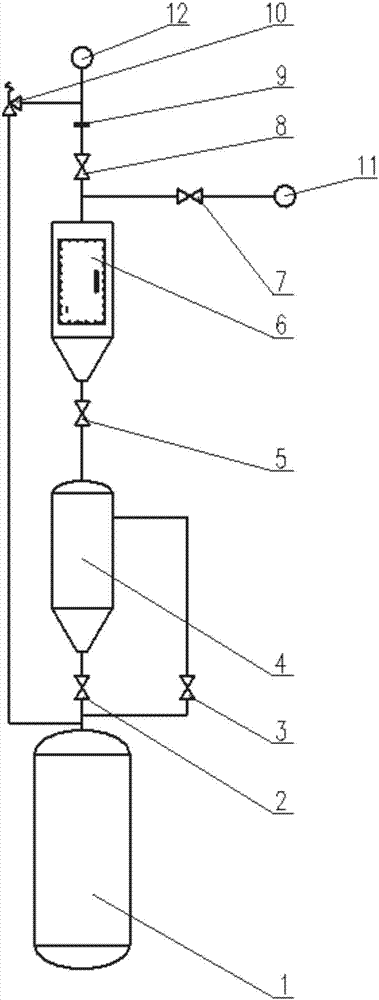

[0019] A gas pressure equalization and release device for multi-stage dust removal of pressure vessels, including three parts: a pressure equalization device, a release device and a safety device; 5. The cyclone dust collector 4, the shut-off valve 1 and the pressure vessel 1 are connected in series, and a pressure equalization valve 7 is provided between the pressure equalizing air source 11 and the bag dust collector 6, and between the bag dust collector 6 and the cyclone dust collector 4 There is a cut-off valve 25 between them, and a cut-off valve 2 is set between the cyclone dust collector 4 and the pressure vessel 1; the release device consists of a pressure vessel 1, a release valve 3, a cyclone dust collector 4, a cut-off valve 25, and a bag filter 6. Shut-off valve 3 8, orifice plate 9 and gas discharge pipe 12 are connected in series, and a release valve 3 is provided between the pressure vessel 1 and the cyclone dust collector 4, and a discharge valve 3 is provided b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com