System for removing corrosive substances in coal gas obtained by dry dedusting of blast furnace and process thereof

A technology for ironmaking blast furnace and dry dust removal, which is applied in dust collectors, petroleum industry, combustible gas purification, etc. It can solve the problems of inability to remove acidic corrosive substances in gas, threats to the safe and stable operation of gas systems, and damage to pipeline networks and user facilities and other issues, to achieve the effect of ensuring power generation efficiency, simple and easy installation, and reducing salt content and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

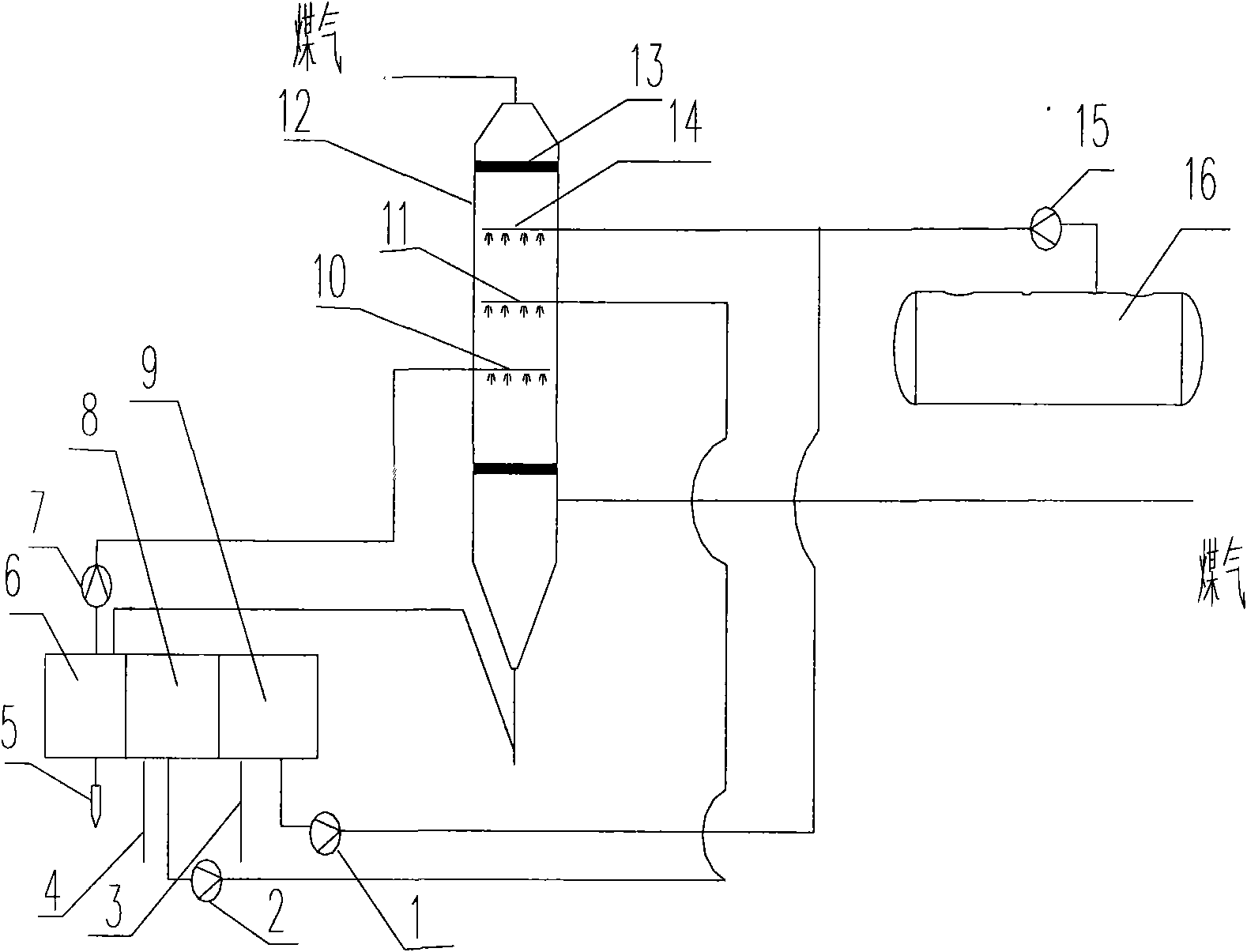

[0034] Attached below figure 1 The patented invention is described in further detail: the specific implementation of the patented invention is as follows:

[0035] Such as figure 1 Shown:

[0036] Prepare solid NaOH with a purity of more than 96% and demineralized water in the alkali tank 16 to prepare lye with a concentration of 20%, and inject it into the demineralized water pipeline through the alkali pump 15, and the demineralized water pump 1 pressurizes the demineralized water in the demineralized water well 9 to carry the alkali The lye is sprayed into the cleaning tower 12 through the nozzle 14, and the lye can neutralize the acidic substances in the blast furnace gas flowing through the tower, increase the pH value of the gas condensate water, reduce the acidity of the gas condensate water, reduce the corrosion strength, and soften The water system plays the role of assisting spraying, improving the atomization effect and replenishing water, and the softened water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com