System and technology for environmentally-friendly comprehensive treatment of iron making blast furnace gas

A blast furnace gas, comprehensive treatment technology, applied in blast furnace, blast furnace details, blast furnace parts and other directions, can solve the problems of failing to meet ultra-clean emission requirements, affecting the normal production of iron and steel enterprises, failing to meet national environmental protection requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

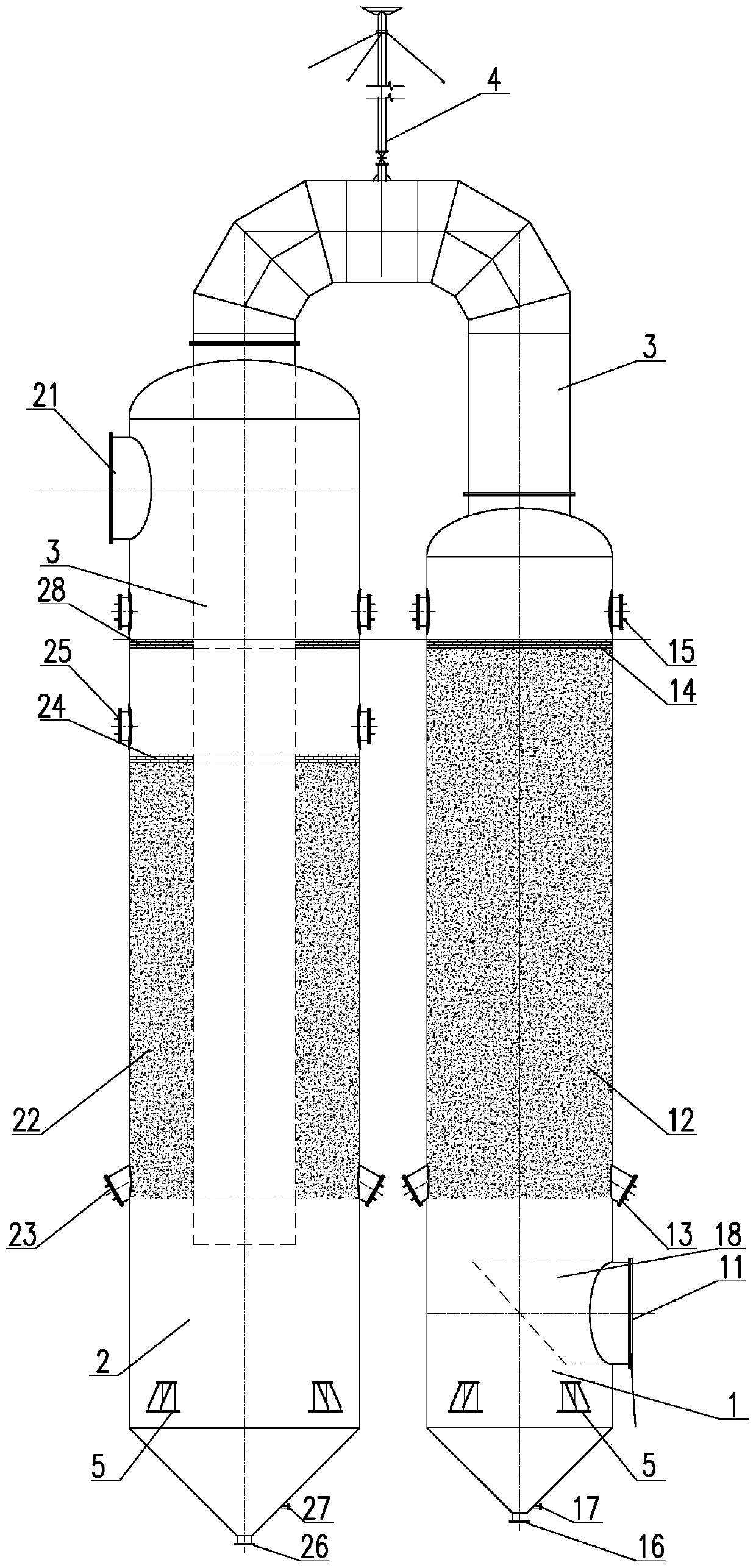

[0024] The structure and features of the present invention will be described in detail below in conjunction with the drawings and embodiments. It should be noted that various modifications can be made to the embodiments disclosed herein, therefore, the embodiments disclosed in the specification should not be regarded as limitations on the present invention, but only as examples of embodiments, and its purpose is to make the present invention The features of the invention are self-evident.

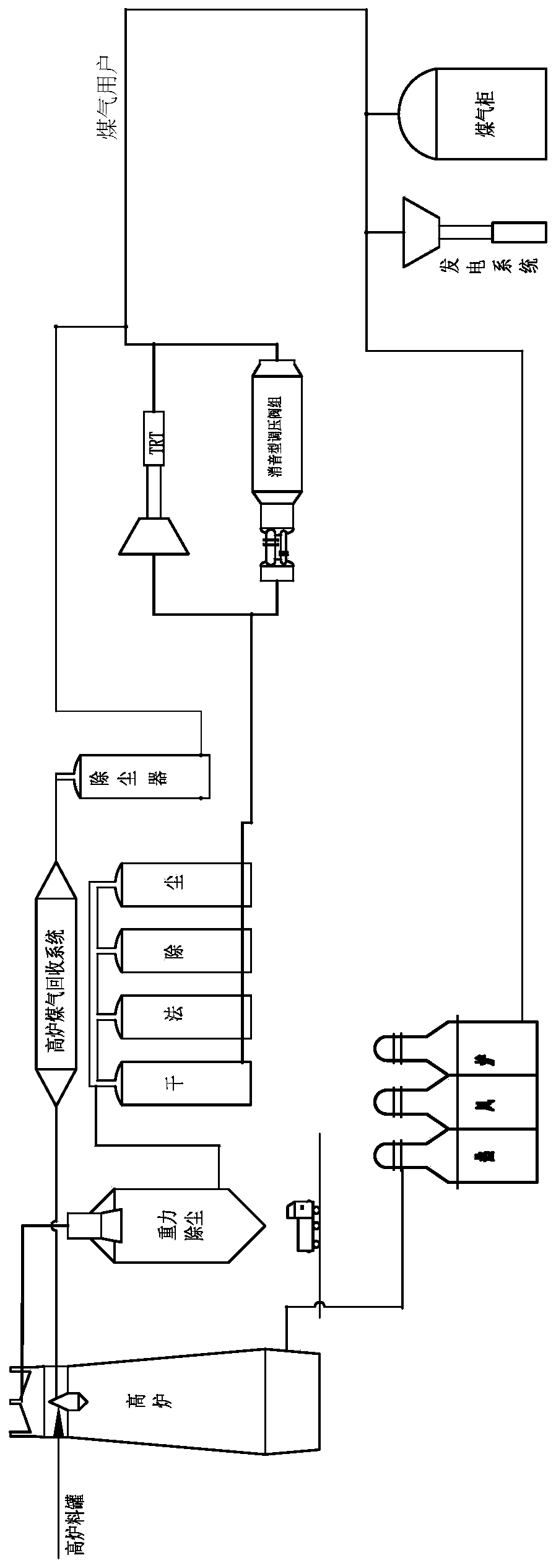

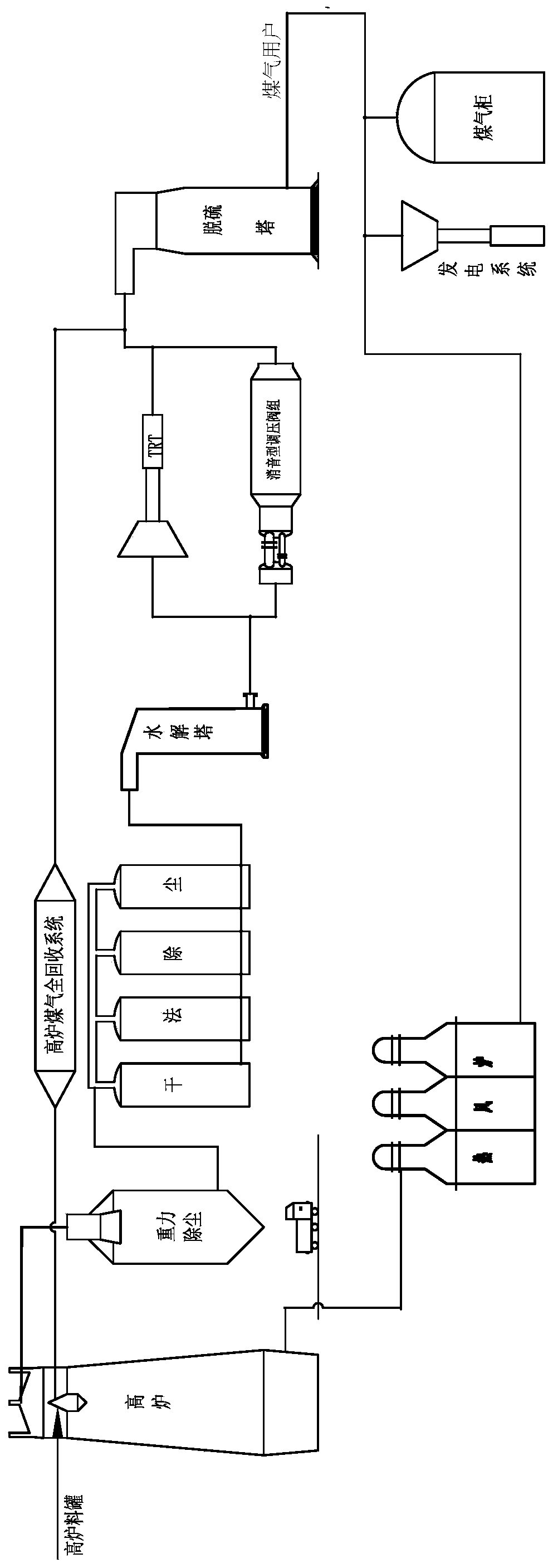

[0025] Since blast furnace gas contains CO, CO 2 , N 2 In addition, it also contains COS, H 2 S, Cl - , dust and other components, it is not enough to dedust the blast furnace gas only. At the same time, in order to reduce the phenomenon of repeated purchase of flue gas desulfurization equipment for blast furnace gas users (such as power plants, ironworks, and steelworks), such as figure 2 As shown, the present invention carries out pretreatment to blast furnace gas, dust, COS, H in bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com