Dry dust collection method and apparatus for blast furnace gas

A technology for dry dust removal and blast furnace gas, applied in the direction of dust collectors, etc., can solve the problems of only dispersing but not processing low temperature gas, and achieves the effects of good quality, obvious environmental protection effect and more gas recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

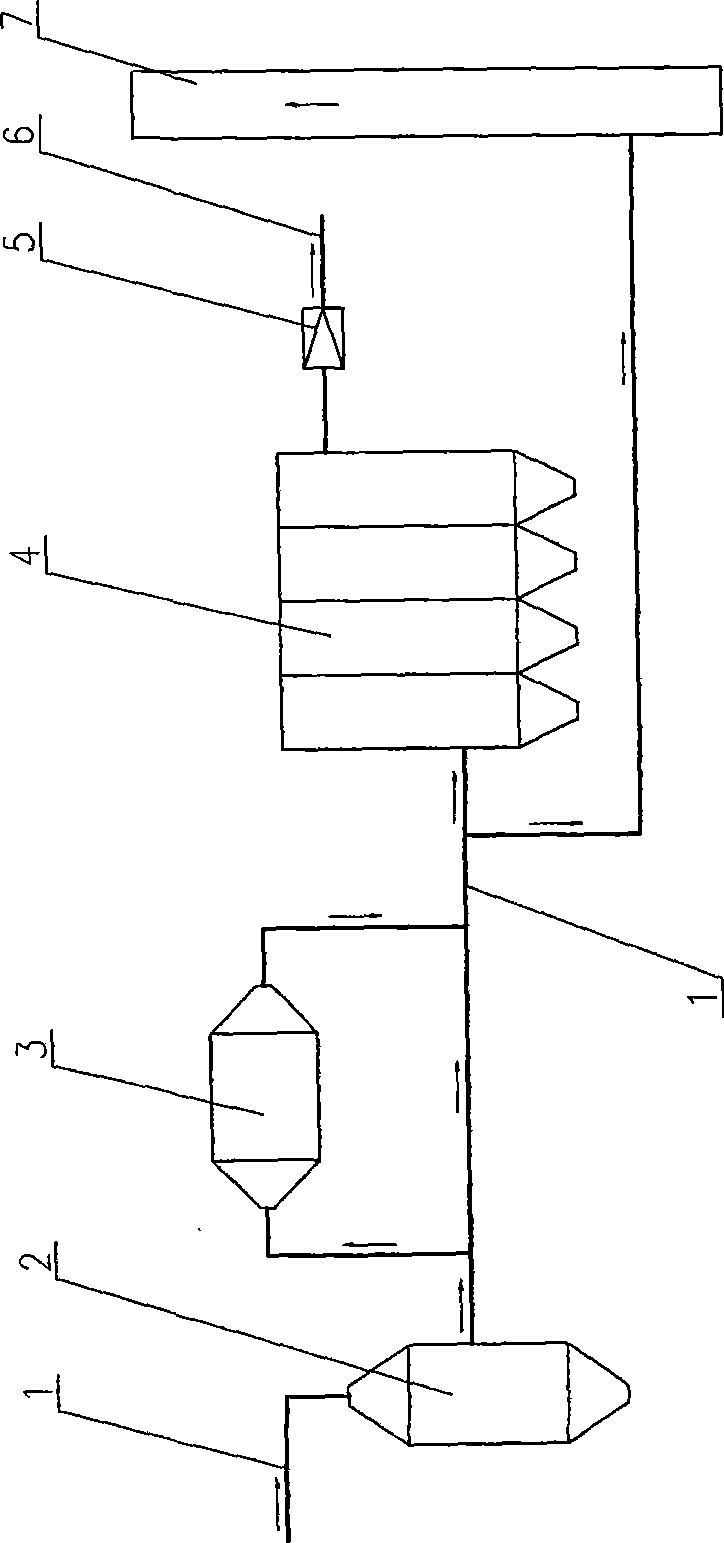

[0011] see figure 1 , the present invention is a new blast furnace gas dry dedusting process with a gas dehumidification device, which includes a raw gas pipeline 1, a gravity dust collector 2, a gas dehumidification device 3, a bag filter 4, a pressure reducing valve group 5, and a clean gas Pipeline 6 and release chimney 7.

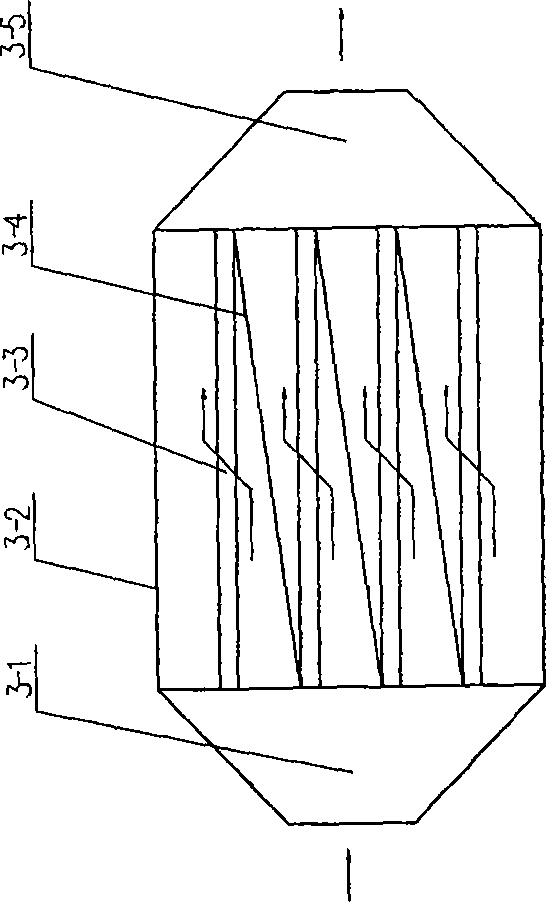

[0012] The gas dehumidifier 3 is a cylindrical structure. The gas dehumidifier 3 includes an air inlet pipe 3-1, a housing 3-2, a dehumidification layer (containing a hygroscopic agent) 3-3, a partition plate 3-4, and an air outlet pipe 3-5. And the dehumidification layer in the housing is a multi-layer dehumidification layer, and a gas partition plate is arranged between each dehumidification layer, so that the gas is divided into several paths and passes through each dehumidification layer respectively; the inlet pipe 3-1 and the outlet pipe 3-5 are arranged in the housing superior.

[0013] One end of the dehumidification layer (3-3) is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com