Method and device for recovering pressure-equalized coal gas at top of blast furnace

A recovery method and recovery device technology, applied in the direction of dust collectors, etc., can solve the problems of high dust content in gas, high CO content in gas, and high noise in the emission process, so as to achieve clean gas recovery, improve the environment, and reduce emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

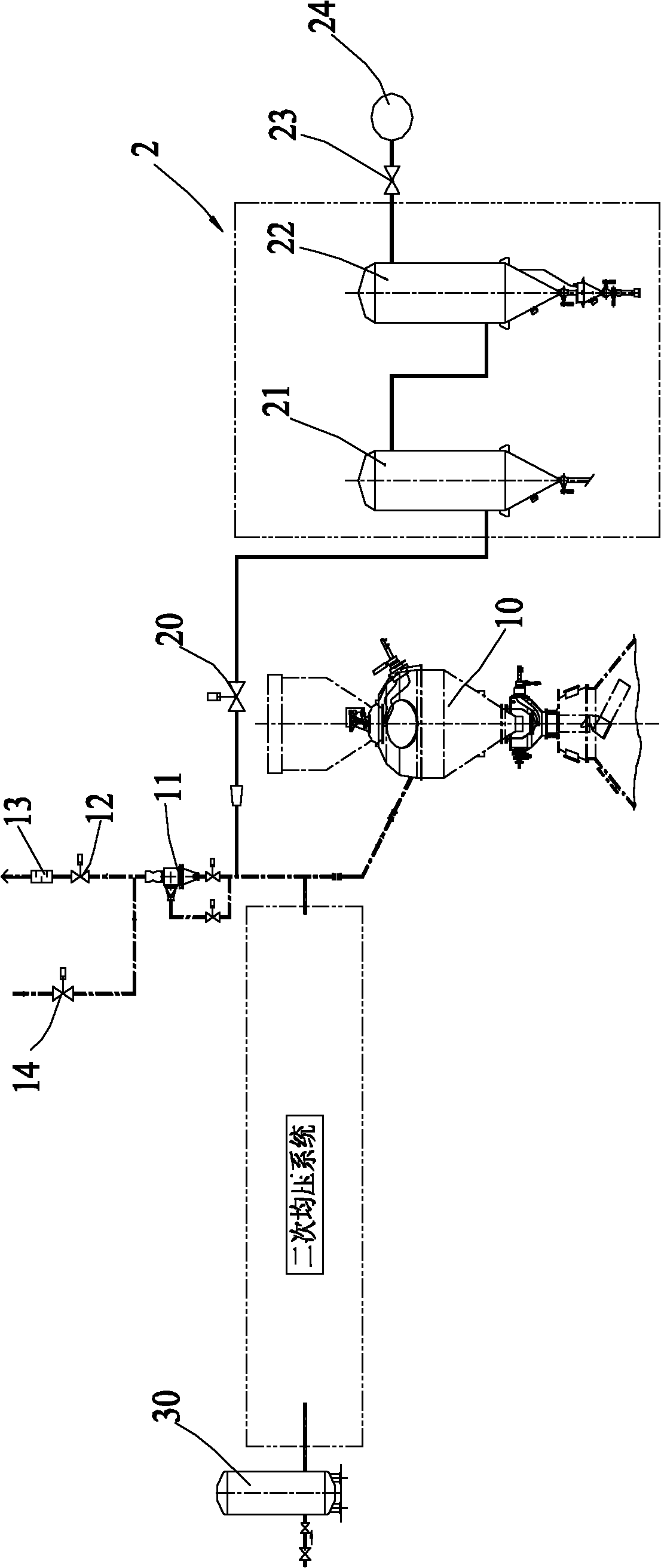

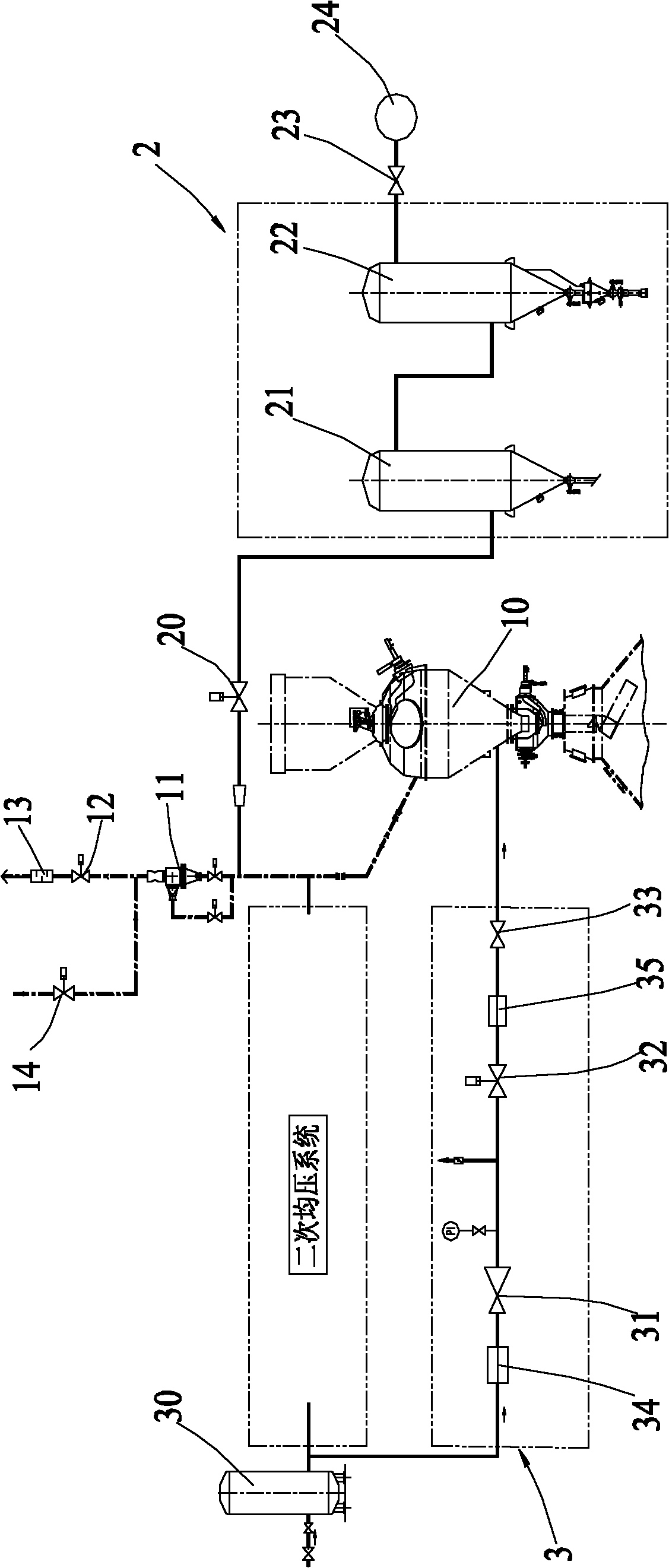

[0035] The blast furnace roof pressure equalization gas recovery method proposed by the present invention mainly includes a natural recovery step: after the blast furnace charging system enters the charging process to the material tank, the gas recovery valve of the pressure equalization gas recovery device is opened, and the clean gas pipe network is opened. The pressure equalizing gas discharged from the material tank first enters the buffer tank, then enters the bag filter, and enters the clean gas pipe network after being dedusted by the bag filter. The dry-type bag dust collector adopted in the present invention can naturally recycle the pressure-equalized gas on the top of the blast furnace, which can overcome the problems existing in the prior art, and without consuming a large amount of water and electric energy, the gas in the bell-less tank can be recovered Part of the pressure-equalized gas is recovered, and the device of the invention has a simple structure and low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com