Group control method of blast furnace gas cloth bag dust catcher system for pipeline dust conveying

A technology of bag dust removal and blast furnace gas, applied in the direction of separation methods, dust collectors, chemical instruments and methods, etc., can solve problems such as insufficient protective interlock control, achieve the effect of improving operating efficiency and prolonging the service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

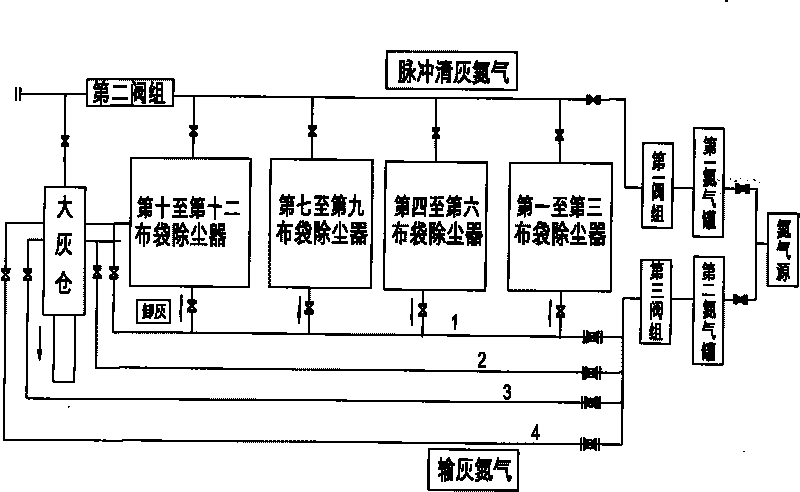

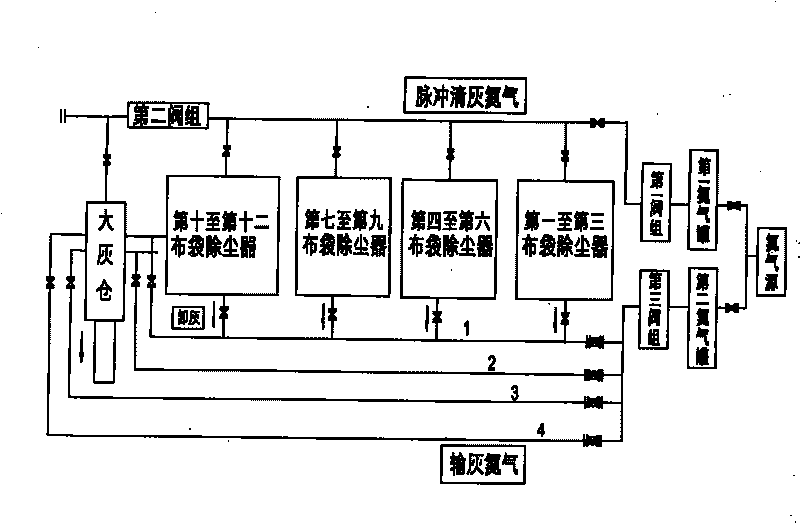

[0029] The multi-level grouping control method for the blast furnace gas bag dust removal system in the form of pipeline ash transportation provided by the present invention is to use a grouping control device for the blast furnace gas bag dust removal system for pipeline ash transportation to realize the blast furnace gas bag dust removal The multi-level grouping control of the system, the structure of the device is as follows figure 1 Shown: It includes a large ash bin, multiple sets of bag filters and valve groups. Among them: the dust removal interface of each bag filter is connected with the pulse cleaning nitrogen pipeline through the pulse valve, and the ash discharge end of each bag filter is respectively connected with the corresponding ash conveying nitrogen pipeline through the dust discharge valve; one end of the pulse cleaning nitrogen pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com