Five-in-one functional facing shaving board and preparing method thereof

A particleboard and functional technology, which is applied in the field of five-in-one functional veneer particleboard and its preparation, can solve the problems of low production efficiency, high cost, no flame retardant function, etc., and achieves high environmental protection level, stable physical and chemical properties, and no residue. The effect of formaldehyde pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The embodiment of the present invention also provides a method for preparing the five-in-one functional decorative particleboard according to the above embodiment, comprising the following steps:

[0039] S1: Weigh each raw material in proportion, soak and dry the wooden shavings in a flame retardant, sort out the dry shavings of the coarse core layer and the dry shavings of the fine surface layer, and then add wave absorbing agent and mix well;

[0040] S2: After mixing the environment-friendly high moisture-proof glue and water into glue, add them to the core layer and the surface layer of dry shavings respectively. After mechanical stirring, mix the coarse core layer dry shavings and fine surface layer dry shavings containing the environment-friendly high moisture-proof glue in proportion. Paving, and flat pressing the paved slab into a three-in-one functional particleboard under a pressure of 30Mpa and a temperature of 170-210°C;

[0041] S3: Mix melamine resin glue...

Embodiment 1

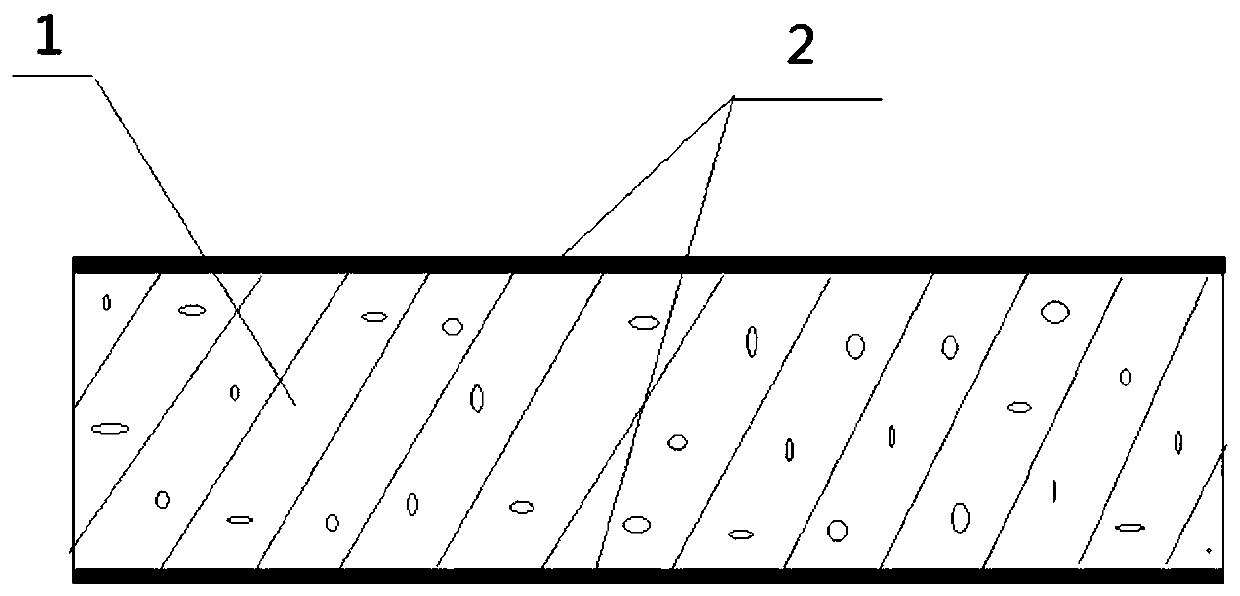

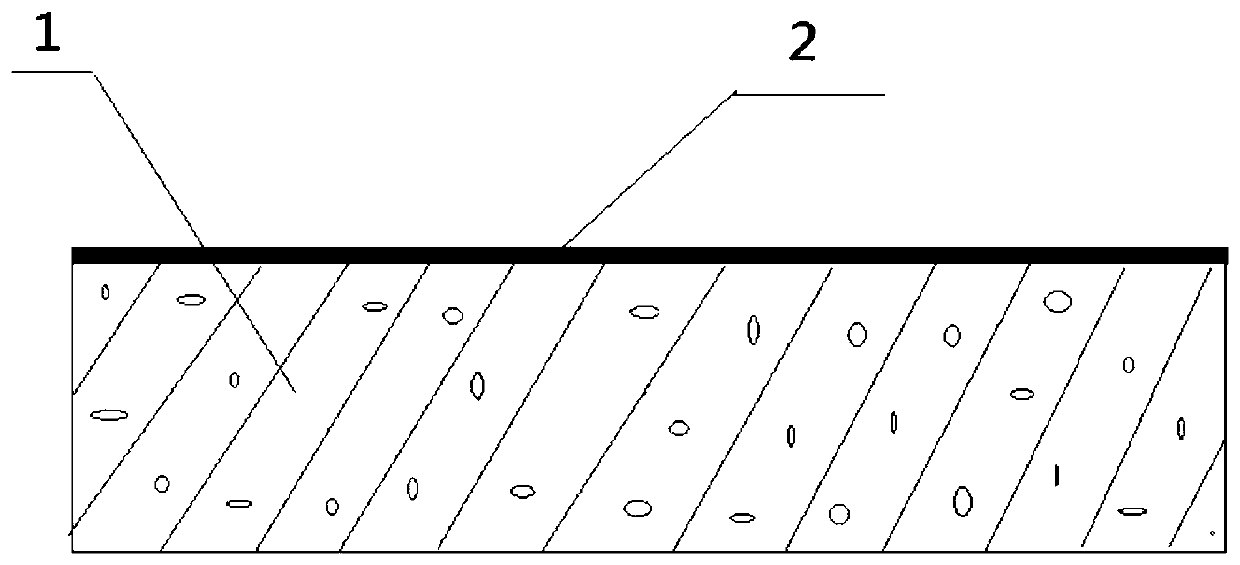

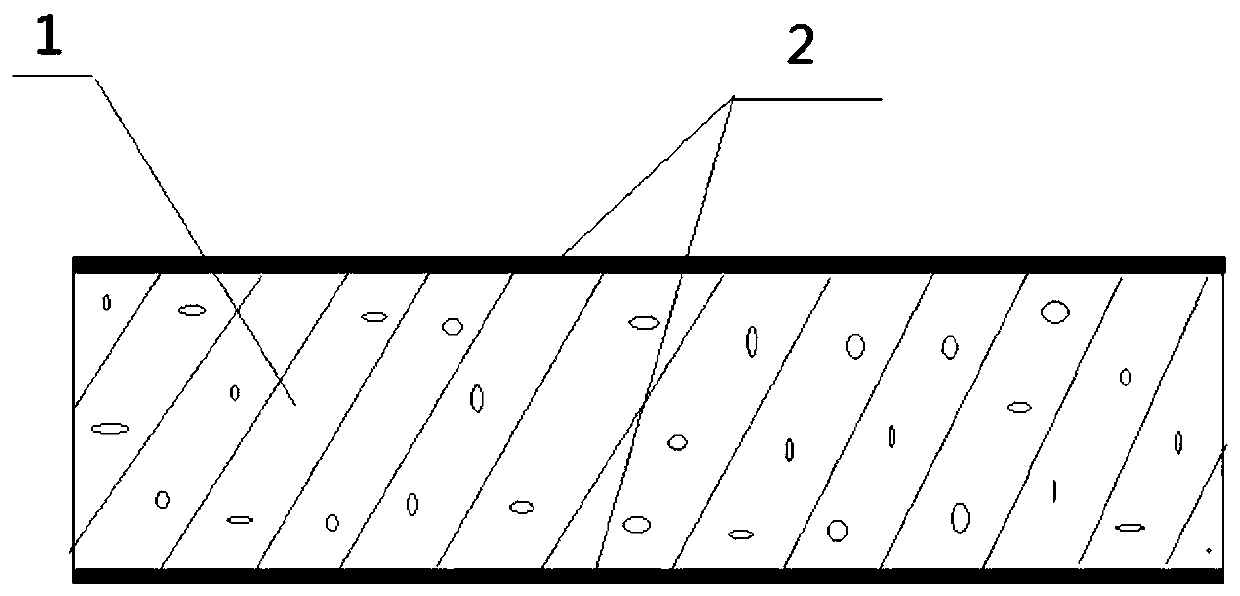

[0046] The five-in-one functional decorative particleboard is composed of a three-in-one functional particleboard 1 and a composite nano-decorative film layer 2 attached to one side (such as figure 2 shown) or composed of a three-in-one functional particle board 1 and a composite nano-decorative film layer 2 attached to both sides (such as figure 1 shown).

[0047] Specifically, the preparation method of the five-in-one functional decorative particleboard includes the following steps:

[0048] (1) Preparation of three-in-one functional particleboard:

[0049] Weigh each raw material in proportion, soak and dry the wooden shavings in a flame retardant, sort out the dry shavings of the coarse core layer and the dry shavings of the fine surface layer, and then add the wave absorbing agent and mix them evenly;

[0050] After mixing the environment-friendly high moisture-proof glue and water into glue, add them to the core layer and the surface dry shavings respectively, and aft...

Embodiment 2

[0059] The preparation method of the five-in-one functional decorative particleboard is the same as that in Example 1, the difference is that the raw materials of the three-in-one functional particleboard include (per cubic consumption) 650kg of wood shavings with a water content of 1.5-3%, 5kg of demineralized water according to the national standard, and high environmental protection. Moisture-proof glue 115kg, wave absorbing agent 25kg, flame retardant 36kg.

[0060] Among the raw materials of the three-in-one functional particle board, the raw materials (amount per ton) of environmentally friendly high moisture-proof glue are: 650kg of formaldehyde, 400kg of urea, 40kg of melamine, 10kg of sodium hydroxide, and 3kg of formic acid. The above raw materials are obtained through addition and polycondensation reactions. The indicators of this environmentally friendly high moisture-proof adhesive are as follows: a. Appearance: white or milky white, without mechanical impurities; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com