Plastic injection-pressing compound forming process and its mould

A composite molding and injection pressure technology, which is applied to the plastic injection-pressing composite molding process and the transformation of its molds, can solve the problems of difficulty in cleaning the feeding chamber, a large number of pouring systems, and troublesome production operations, achieving a good production environment, improving Production environment, easy assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

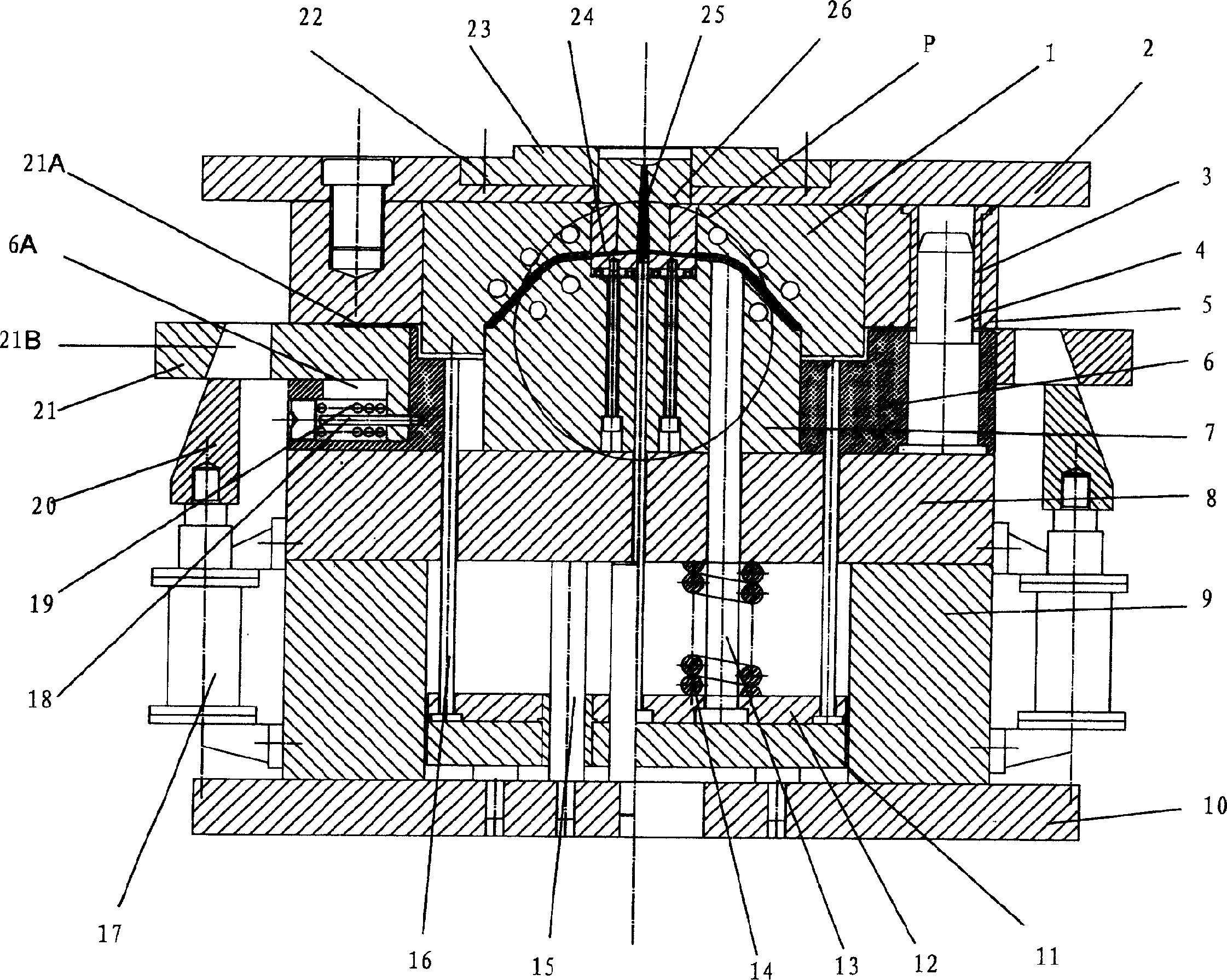

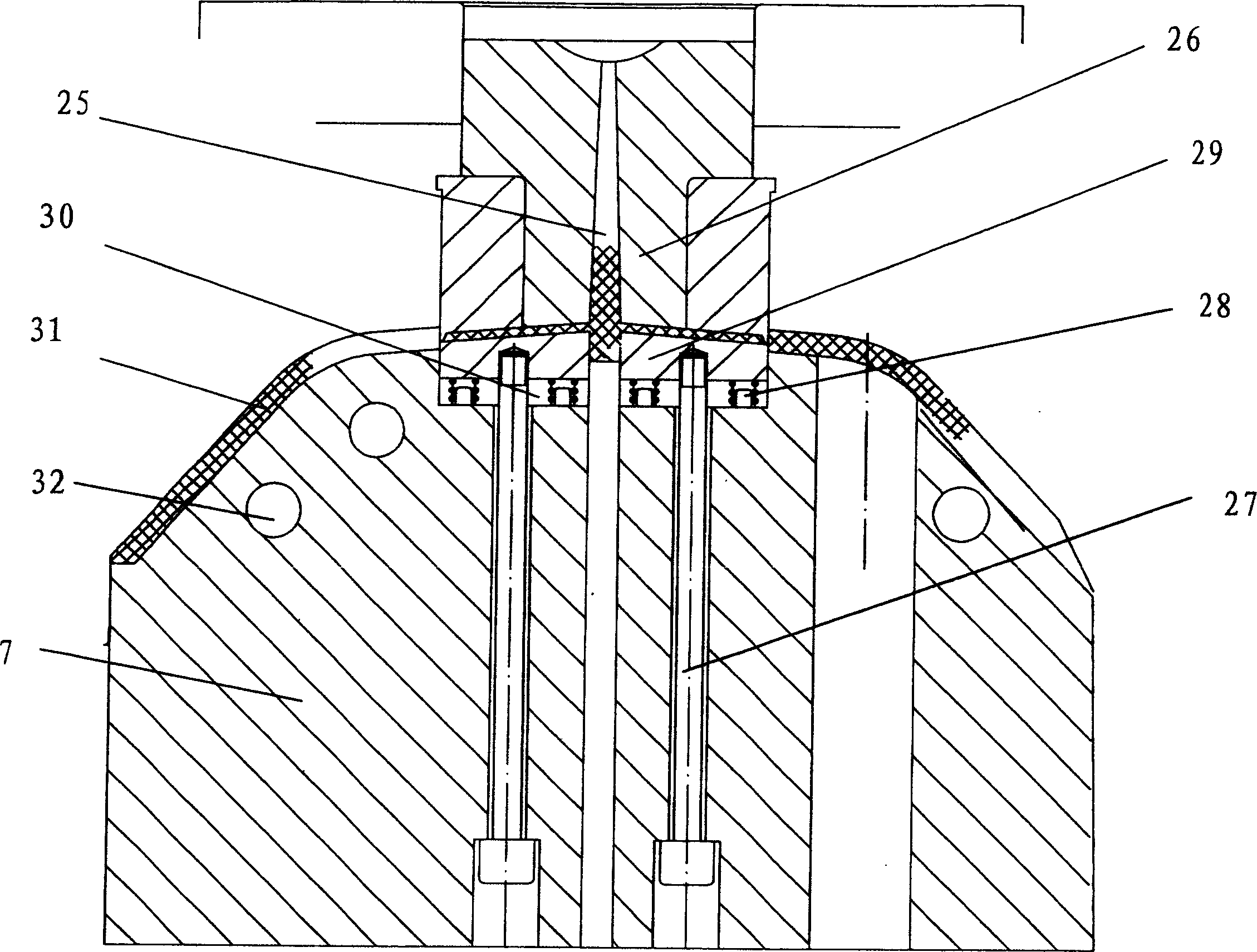

[0023] The plastic injection-compression composite molding process of the present invention includes the following steps:

[0024] (1) Plastic raw materials are heated and plasticized in the barrel of the injection machine;

[0025] (2) Under the action of the two-stage mold-closing and mold-opening mechanism, the mold is first-stage closed to form a closed cavity;

[0026] (3) Under the action of the injection pressure, the molten plastic is ejected from the nozzle at the front end of the barrel and injected into the closed cavity of the mold through the gating system to achieve quantitative filling of the cavity;

[0027] (4) The cavity is heated and insulated to keep the plastic melt at the molding temperature. At the same time, the injection pressure maintains the pressure in the cavity to reach the molding pressure. The mold is closed in two stages to further reduce the distance between the convex mold and the concave mold surface. Realize compression molding;

[0028] (5) Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com