Thermoplastic elastomer surface unitary-core flame-resistant conveying belt and manufacturing method thereof

A technology of thermoplastic elasticity and conveyor belts, which is applied in the direction of conveyors, belts, transportation and packaging, etc., can solve the problems of large equipment investment, decreased belt core strength, and low production efficiency, so as to improve product quality, reduce energy consumption, and improve production efficiency. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

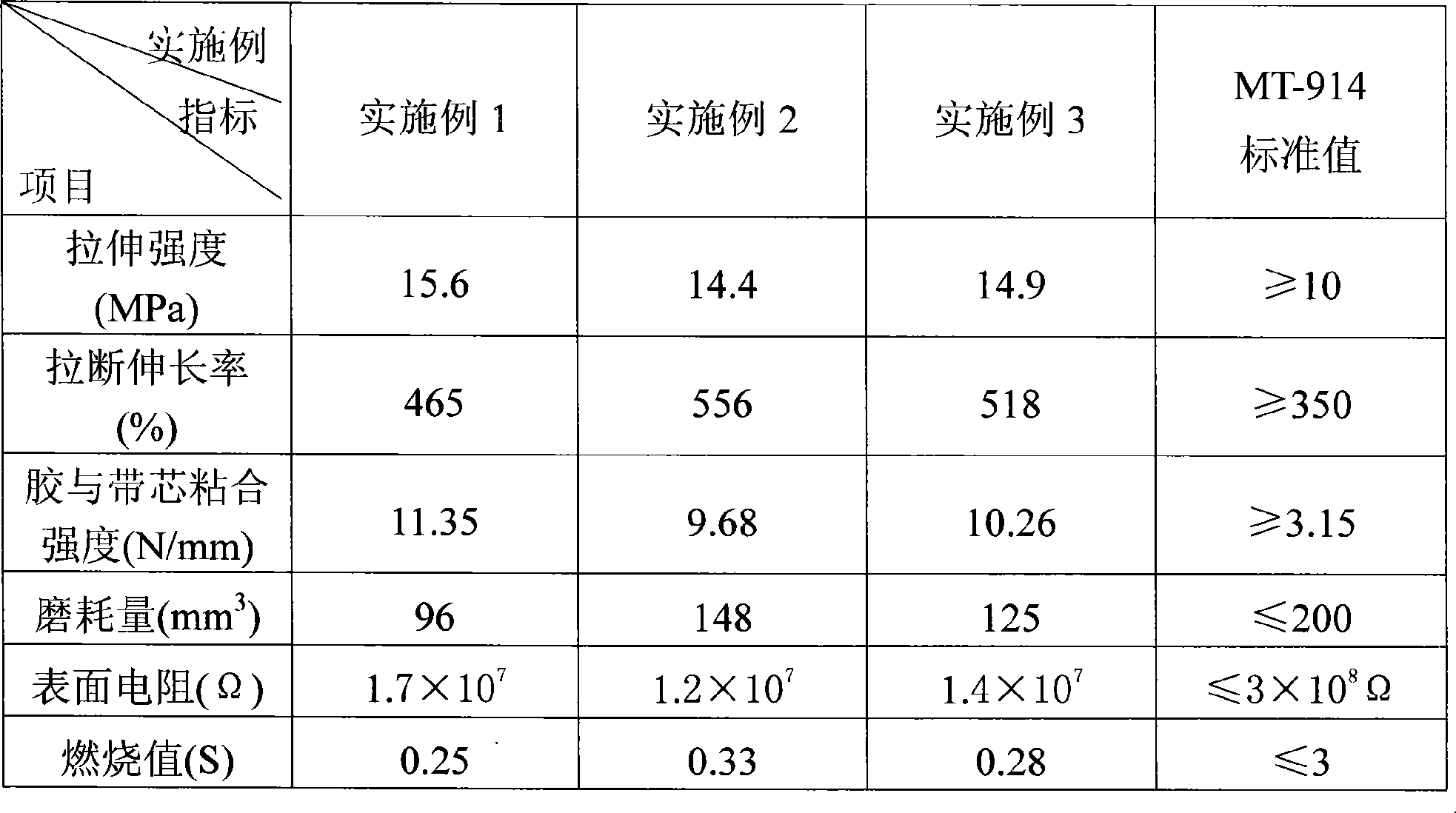

Embodiment 1

[0023] The composition of the cover rubber of the thermoplastic elastomer surface whole core flame-retardant conveyor belt according to the weight ratio is:

[0024] 30 parts of powdered nitrile rubber, 50 parts of polyvinyl chloride, 20 parts of chlorinated polyethylene, 1.5 parts of zinc oxide, 1 part of stearic acid, 0.8 parts of sulfur, 0.6 parts of accelerator M, 0.8 parts of accelerator DM, conductive 15 parts of carbon black, 0.8 parts of antioxidant 4010NA, 12 parts of antimony trioxide, 20 parts of triaryl phosphate, 30 parts of dioctyl ester, 2 parts of tribasic lead sulfate, 1 part of dibasic lead phosphite.

[0025] The manufacture method of the present invention is:

[0026] (1) Provide the skeleton of the whole fabric with the core dipped and plasticized;

[0027] (2) Mix and granulate the above-mentioned covering rubber materials to obtain covering rubber granules:

[0028] i: High-speed mixing: Add PVC, stabilizer, CPE, dioctyl ester (DOP), solid flame retard...

Embodiment 2

[0034] The composition of the cover rubber of the thermoplastic elastomer surface belt core flame-retardant conveyor belt according to the weight ratio is:

[0035] 50 parts of powdered nitrile rubber, 40 parts of polyvinyl chloride, 10 parts of chlorinated polyethylene, 3 parts of zinc oxide, 2 parts of stearic acid, 1.2 parts of sulfur, 0.6 parts of accelerator M, 1.2 parts of accelerator DM, conductive 25 parts of carbon black, 1.2 parts of antioxidant 4010NA, 8 parts of antimony trioxide, 10 parts of aluminum hydroxide, 20 parts of trichloroethyl phosphate, 25 parts of dioctyl ester, 1.5 parts of tribasic lead sulfate, di-salt 1 part of lead phosphite.

[0036] Manufacturing method is the same as embodiment 1.

Embodiment 3

[0038] The composition of the cover rubber of the thermoplastic elastomer surface whole core flame-retardant conveyor belt according to the weight ratio is:

[0039] 40 parts of powdered nitrile rubber, 30 parts of polyvinyl chloride, 30 parts of chlorinated polyethylene, 2.5 parts of zinc oxide, 1.5 parts of stearic acid, 1 part of sulfur, 0.6 parts of accelerator M, 1 part of accelerator DM, conductive carbon black 20 parts, 1 part of anti-aging agent 4010NA, 10 parts of zinc borate, 10 parts of ammonium polyphosphate, 18 parts of dichloropropyl phosphate, 10 parts of chlorinated paraffin, 25 parts of dioctyl ester, 1 part of tribasic lead sulfate, di-salt 1 part of lead phosphite.

[0040] Manufacturing method is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com