High-heat resistance halogen-free fire-retarding polyphenylether and polystyrene composite and preparation method thereof

A polystyrene and polystyrene resin technology, applied in the field of polymer materials and their molding processing, can solve the problems of insufficient flame retardancy, affecting electrical properties, and large dosage, so as to achieve high production efficiency, prevent precipitation, and reduce dosage Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

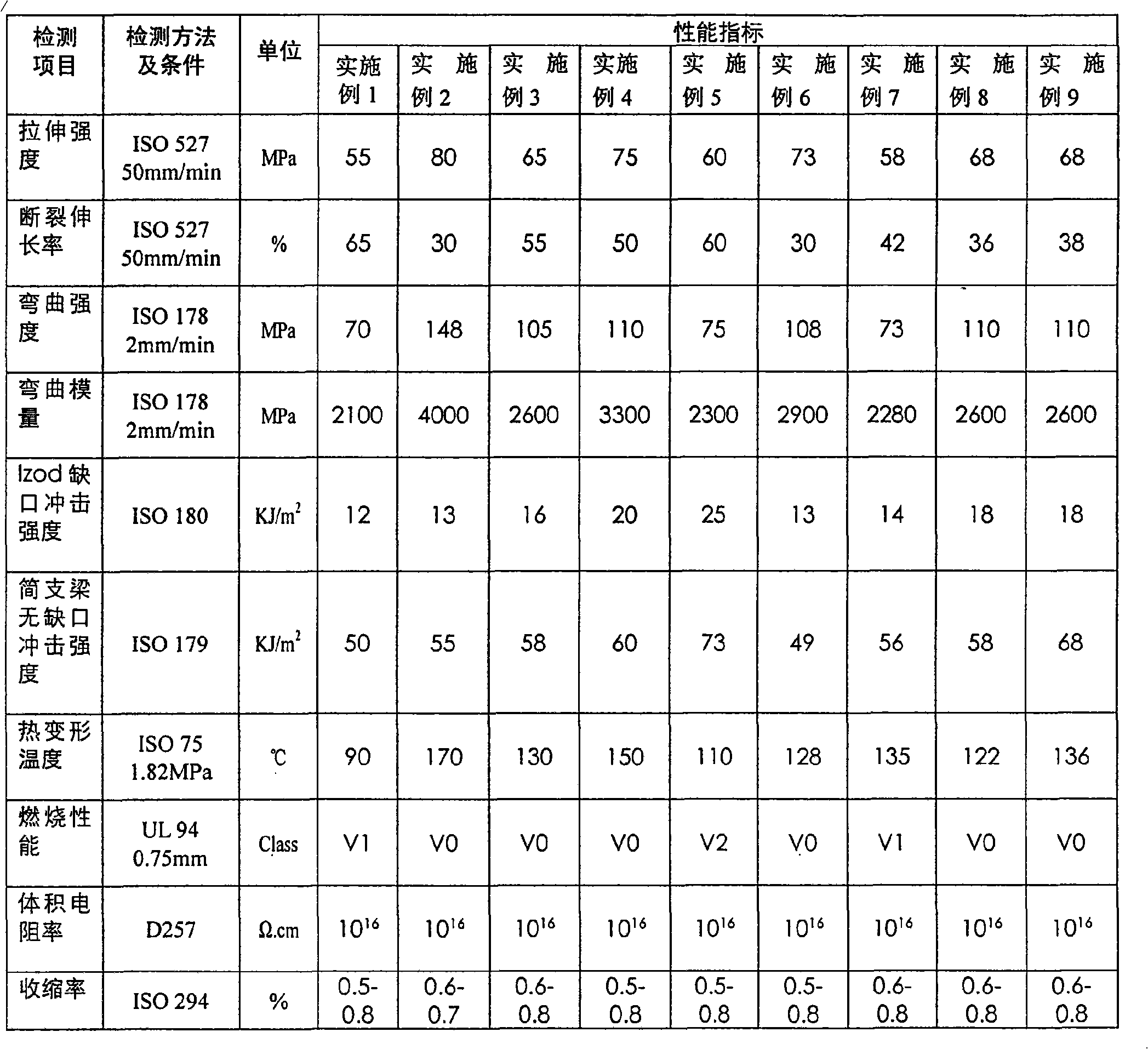

Examples

Embodiment 1

[0020] Formula: 45 parts by weight of polyphenylene ether resin, 40 parts by weight of polystyrene resin, 2 parts by weight of toughening agent (styrene-isoprene-styrene), 12 parts by weight of halogen-free flame retardant (microcapsule 1 weight part of coated red phosphorus, 8 weight parts of triphenyl phosphate, 3 weight parts of tripropyl phosphate), 1 weight part of processing aid (silicone).

[0021] Preparation method: Using high-speed pre-mixing dispersion extrusion process, polyphenylene ether resin, polystyrene resin, microencapsulated coated red phosphorus (purchased from Sichuan Chenguang Chemical, trade name RPM), toughening agent, processing aid Put into the high-mixer, after dispersion and mixing, plasticize and knead through the twin-screw extruder. The liquid flame retardant is evenly dispersed into the PPO / HIPS alloy. The aspect ratio of the twin-screw extruder is 24. There is a set of liquid pump device, temperature control and vacuum exhaust system; the temp...

Embodiment 2

[0023] Formula: 84 parts by weight of polyphenylene ether resin, 10 parts by weight of polystyrene resin, 2 parts by weight of toughening agent (a mixture of styrene-butadiene-styrene and ethylene-propylene rubber in a weight ratio of 1:1), 4 parts by weight of halogen-free flame retardant (1 part by weight of microencapsulated red phosphorus, 2 parts by weight of resorcinol bis(diphenyl phosphate), 1 part by weight of bisphenol bis(diphenyl phosphate)) , 0.3 parts by weight of processing aid (fatty acid amide).

[0024] Preparation method: Using high-speed pre-mixing dispersion extrusion process, polyphenylene ether resin, polystyrene resin, microencapsulated coated red phosphorus (purchased from Sichuan Chenguang Chemical, trade name RPM), toughening agent, processing aid Put it into a high-mixer, after dispersion and mixing, plasticize and knead through a twin-screw extruder, and at the same time, resorcinol bis(diphenyl phosphate), bisphenol bis(diphenyl phosphate) ) Liqu...

Embodiment 3

[0026]Prescription: polyphenylene ether resin is 59 weight parts, and polystyrene resin is 25 weight parts, toughening agent (styrene-butadiene-styrene and hydrogenated styrene-isoprene-styrene by weight 1: 2) 4 parts by weight, 10 parts by weight of halogen-free flame retardant (3 parts by weight of microencapsulated red phosphorus, 2 parts by weight of triethyl phosphate, 4 parts by weight of bisphenol A bis(two xylyl phosphate) , xylyl triethylphenyl phosphite 1 weight part), processing aid (organic silicone oil) 2 weight parts.

[0027] Preparation method: adopt high-speed pre-mixing dispersion extrusion process, add polyphenylene ether resin, polystyrene resin, microencapsulated coated red phosphorus (purchased from Lianyungang Xintuo Siliconization Technology Co., Ltd.), toughening agent, and processing aids High mixer, after dispersing and mixing, plasticize and knead through a twin-screw extruder, and at the same time triethyl phosphate, bisphenol A bis(bisxylyl phosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com