Weather resistant wood-grain imitating PVC plastic profiled bar and method for manufacturing same

A technology of imitating wood grain and profiled material, applied in the field of weather-resistant color PVC plastic profile and its manufacturing, can solve the problems of inconsistent surface color of products, disappearance of wood grain effect, strict process requirements, etc., to achieve uniform color and wood grain effect throughout the body , Improve the durability of weather resistance, the effect of simple molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

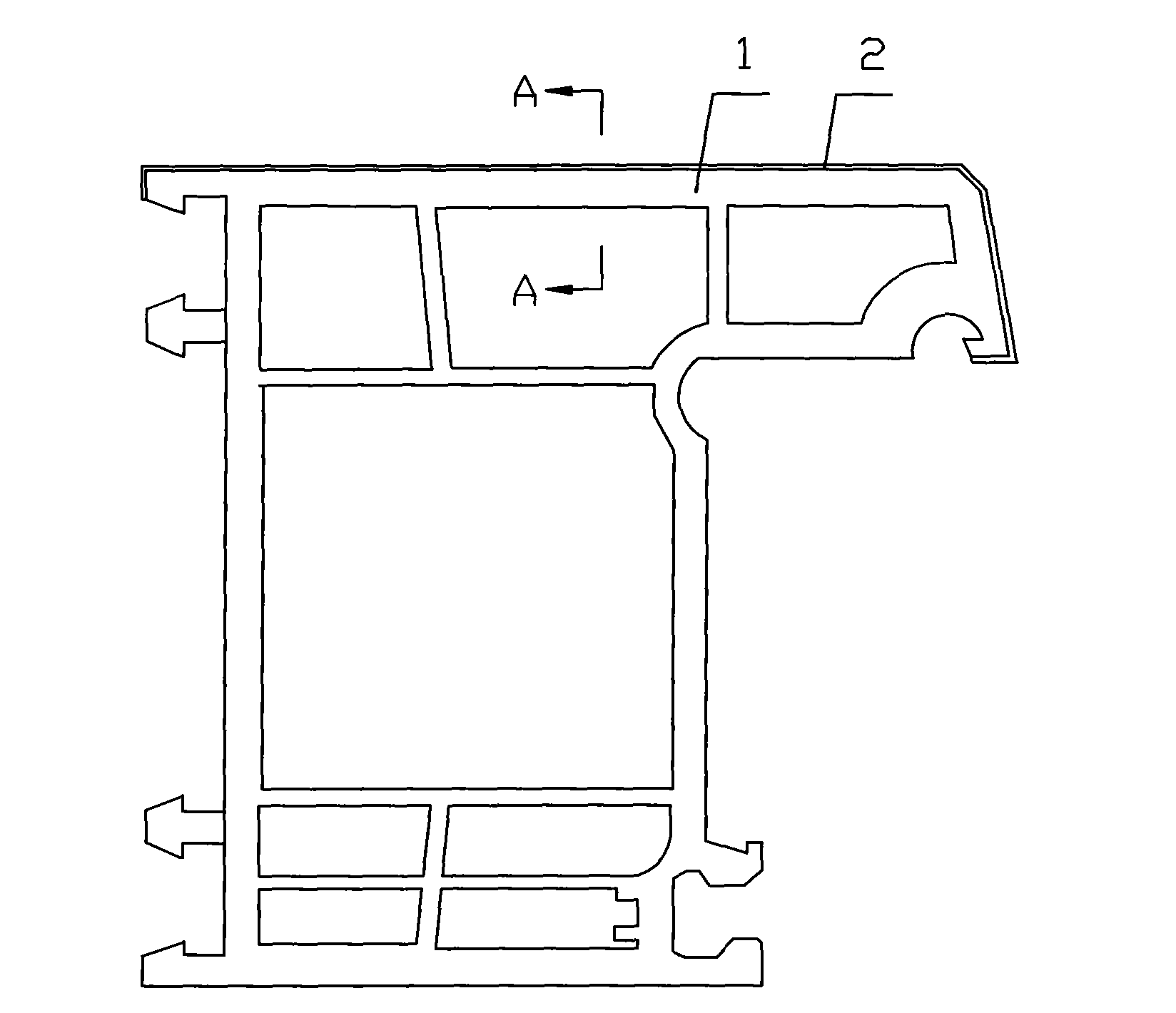

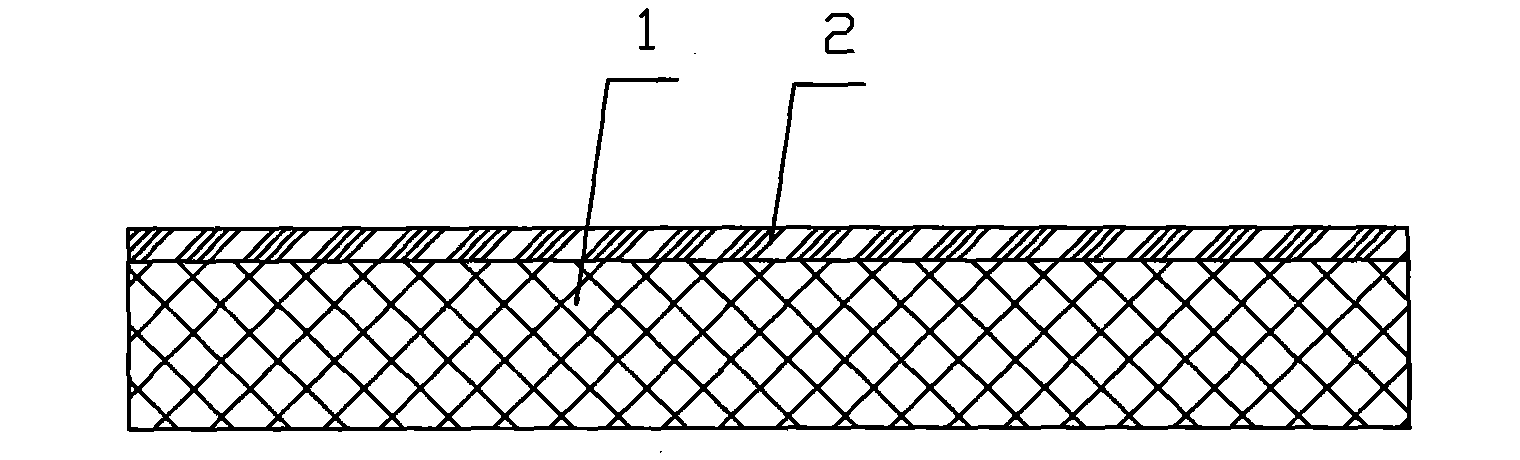

[0044] Such as figure 1 , figure 2 The weather-resistant color PVC plastic profile shown uses transparent PMMA as the transparent material layer 2 with high weather resistance. The raw material is colorless. It is plasticized and extruded in an auxiliary extruder. The thickness of the transparent material layer 2 with high weather resistance is About 0.2mm. Use walnut color powder to prepare dry blend, and mix walnut color masterbatch as PVC profile 1. The dry blend powder formula is as follows in parts by weight: PVC 100 parts, chlorinated polyethylene CPE 9 parts, processing aid ACR 1.5 parts, stabilizer 4.5 parts, calcium carbonate 10 parts, walnut color powder 0.8 parts, titanium dioxide 0.6 part, 0.3 part of lubricant; the addition amount of walnut masterbatch is 4% of the total weight of dry mixed powder.

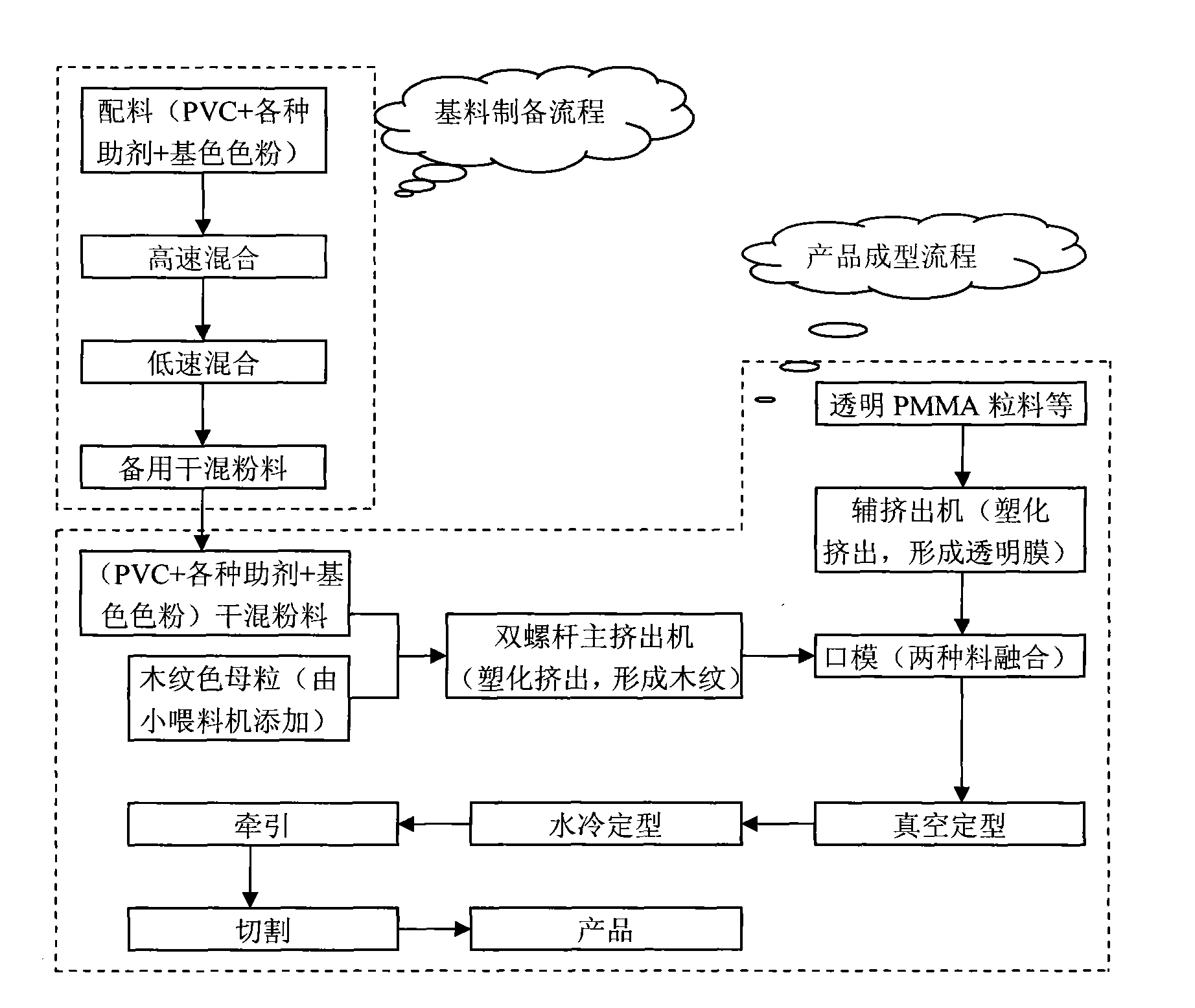

[0045] Such as image 3 As shown, the production process of the present invention is as follows:

[0046] ① Combine PVC, CPE, processing aids, stabilizers, calcium carbo...

Embodiment 2

[0052] Use oak color powder to prepare dry mixture, and use oak color masterbatch as PVC profile 1. The formula of dry-mixed powder in parts by weight is as follows: PVC 100 parts, chlorinated polyethylene CPE 12 parts, processing aid ACR 2 parts, stabilizer 6 parts, calcium carbonate 5 parts, oak base color toner 1.2 parts, titanium dioxide 1.5 parts Parts, 0.8 parts of lubricant; adding amount of oak masterbatch is 5% of the total weight of dry mixed powder. Other technical features of this embodiment are as described in Embodiment 1.

[0053] Of course, the present invention can also select other embodiments according to the requirements of the product. The specific requirements are as follows:

[0054] Weather-resistant transparent layer: It is required to select a material with good transparency and weather resistance, with special optical effects, and the material must be suitable for plasticizing and extrusion; for example, PMMA or other materials obtained through modificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com