Method for preparing wood-plastic composite material

A wood-plastic composite material and material technology, which is applied in the field of wood-plastic composite material preparation, can solve the problems of material quality decline, large proportion of plastics, and insufficient combination of plastic and wood fiber, so as to reduce production costs, reduce molecular weight, and reduce dosage. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

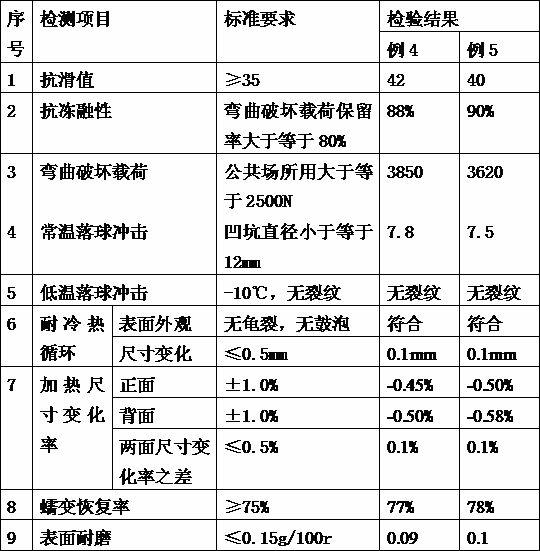

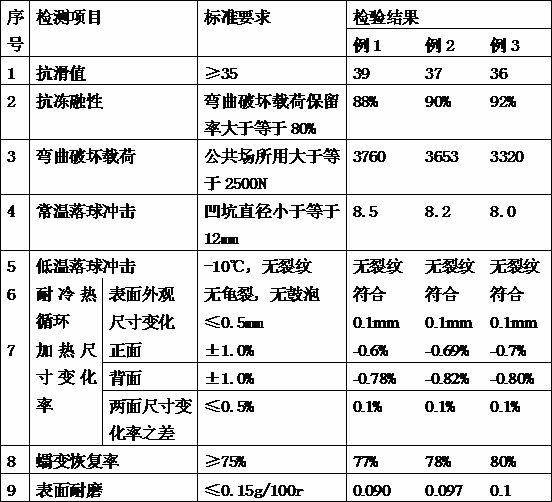

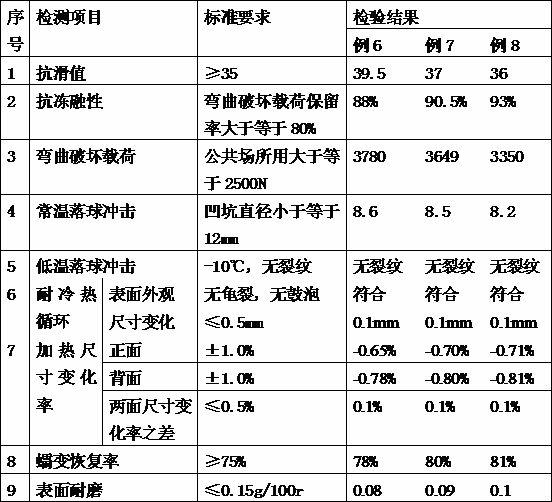

Examples

preparation example Construction

[0029] The specific embodiment of the present invention provides a kind of preparation method of wood-plastic composite material, it is characterized in that: it comprises the following steps:

[0030] (1) Pretreatment: Pretreat the wood fibers with a chemical graft modifier to eliminate the polarity of the wood fibers; the specific method of the pretreatment is to stir the wood fibers at high speed, and when the temperature reaches 105-115°C While adding the chemical grafting modifier, continue to stir at high speed, stop stirring when the temperature reaches 120-125°C, and wait for use.

[0031] This step mainly uses the frictional heat generation of high-speed stirring to remove excess moisture in the wood fibers; and completes the chemical modification of the wood fibers with the help of high-speed stirring and high shear to eliminate the polarity of the wood fibers as much as possible.

[0032] (2) High-speed blending: PVC resin, pretreated wood fiber and additives are pr...

Embodiment 1

[0069] Follow the steps below to prepare wood-plastic composites:

[0070] (1) Preprocessing:

[0071] ①The mushroom sticks are crushed, dried and screened first, the moisture content of the mushroom sticks is kept within 8% by drying, and the impurities are removed by screening;

[0072] ②Continue to carry out chemical grafting modification treatment: first, stir 90 kg of mushroom sticks that have been crushed, dried and screened at high speed; when the temperature reaches 105 ° C, add 0.1 kg of dicumyl peroxide to make the molecules of wood fibers Active groups are formed at the end of the chain; then add 0.5 kg of titanate coupling agent and continue stirring at high speed; stop stirring when the temperature reaches 120°C, and set aside;

[0073] (2) High-speed blending:

[0074] ① Stir and mix 100kg PVC resin and 6kg heat stabilizer (calcium-zinc composite stabilizer) together at high speed;

[0075] ②When the temperature reaches 75°C, add 2kg of lubricant (using paraff...

Embodiment 2

[0081] Follow the steps below to prepare wood-plastic composites:

[0082] (1) Preprocessing:

[0083] ①The mushroom sticks are crushed, dried and screened first, the moisture content of the mushroom sticks is kept within 8% by drying, and the impurities are removed by screening;

[0084] ②Continue to carry out chemical graft modification treatment: first, stir 105kg mushroom sticks that have been crushed, dried and screened at high speed; when the temperature reaches 110°C, add 0.5kg of dicumyl peroxide to make the molecules of wood fibers Active groups are formed at the end of the chain; then add 2 kg of titanate coupling agent and continue stirring at high speed; stop stirring when the temperature reaches 122°C, and set aside;

[0085] (2) High-speed blending:

[0086] ① Stir and mix 100kg PVC resin and 8kg heat stabilizer (calcium-zinc composite stabilizer) together at high speed;

[0087] ②When the temperature reaches 82°C, add 3kg of lubricant (using paraffin), 10kg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com