Preparation method of high-content superfine inorganic powder master batch for filling plastic

An inorganic powder, high-content technology, applied in the field of preparation of high-content super-magic inorganic powder masterbatch, can solve the problems of discontinuous process, inaccurate measurement, and small bulk density of ultra-fine inorganic powder, and achieve reduction Effect of flying dust and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: The formulation of the preparation method of the high-content ultrafine inorganic powder master batch for plastic filling of the present invention is as follows in terms of mass percentage (wt%):

[0019] Ultrafine layered double hydroxide (20nm) 90

[0020] Activator (silane coupling agent) 0.5

[0021] Dispersant (polyethylene wax) 1

[0022] Lubricant (liquid paraffin) 0.5

[0023] Carrier (polyethylene) 8

[0024] Feeding: 15wt% layered double hydroxide, the additives used and the carrier are fed through the main feed port, 50wt% layered double hydroxide is fed through the first side feed port, and 25wt% layered double hydroxide is fed through Feed from the second side feeding port.

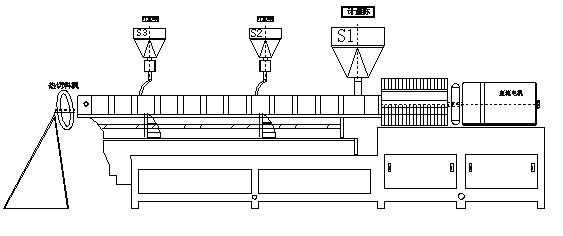

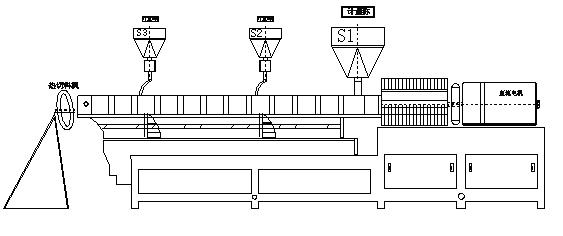

[0025] Extrusion granulation equipment and process: the main feeding port is equipped with three measuring scales, which can accurately measure and feed the carrier, ultra-fine layered double hydroxide and additives respectively; the two side feeding ports are ...

Embodiment 2

[0026] Example 2: The formulation of the preparation method of the high-content ultrafine inorganic powder master batch for plastic filling of the present invention is as follows in terms of mass percentage (wt%):

[0027] Ultrafine talcum powder (500nm) 80

[0028] Activator (aluminate coupling agent) 1

[0029] Dispersant (polypropylene wax) 2

[0030] Lubricant (liquid paraffin) 2

[0031] Carrier (polypropylene) 15

[0032] Feeding: 15wt% talc powder, additives and carriers are fed through the main feed port, 45wt% talc powder is fed through the first side feed port, and 20wt% talc powder is fed through the second side feed port.

[0033] Extrusion granulation equipment and process: the main feeding port is equipped with three measuring scales, which can accurately measure and feed the carrier, ultra-fine inorganic powder and additives respectively; the two side feeding ports are equipped with a measuring scale and side feeding The material system can accurat...

Embodiment 3

[0034] Example 3: The formulation of the preparation method of the high-content ultrafine inorganic powder master batch for plastic filling of the present invention is as follows in terms of mass percentage (wt%):

[0035] Ultrafine silica (3μm) 85

[0036] Activator (aluminate coupling agent) 2

[0037] Dispersant (polyethylene wax) 2

[0038] Lubricant (stearic acid) 1

[0039] Carrier (polypropylene) 10

[0040] Feeding: 20wt% white carbon black, additives and carriers used are fed through the main feeding port, 35wt% white carbon black is fed through the first side feeding port, and 30wt% white carbon black is fed through the second side feeding port.

[0041] Extrusion granulation equipment and process: the main feeding port is equipped with three measuring scales, which can accurately measure and feed the carrier, ultra-fine inorganic powder and additives respectively; the two side feeding ports are equipped with a measuring scale and side feeding The mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com