Reproduction new method for waste elastomer and plastic

An elastomer and a new method of technology, applied in the field of environmental protection collaborative recycling and waste recycling, can solve problems such as dust pollution, continuous production, and coarse particle size, and achieve the effect of eliminating the impact of flow fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

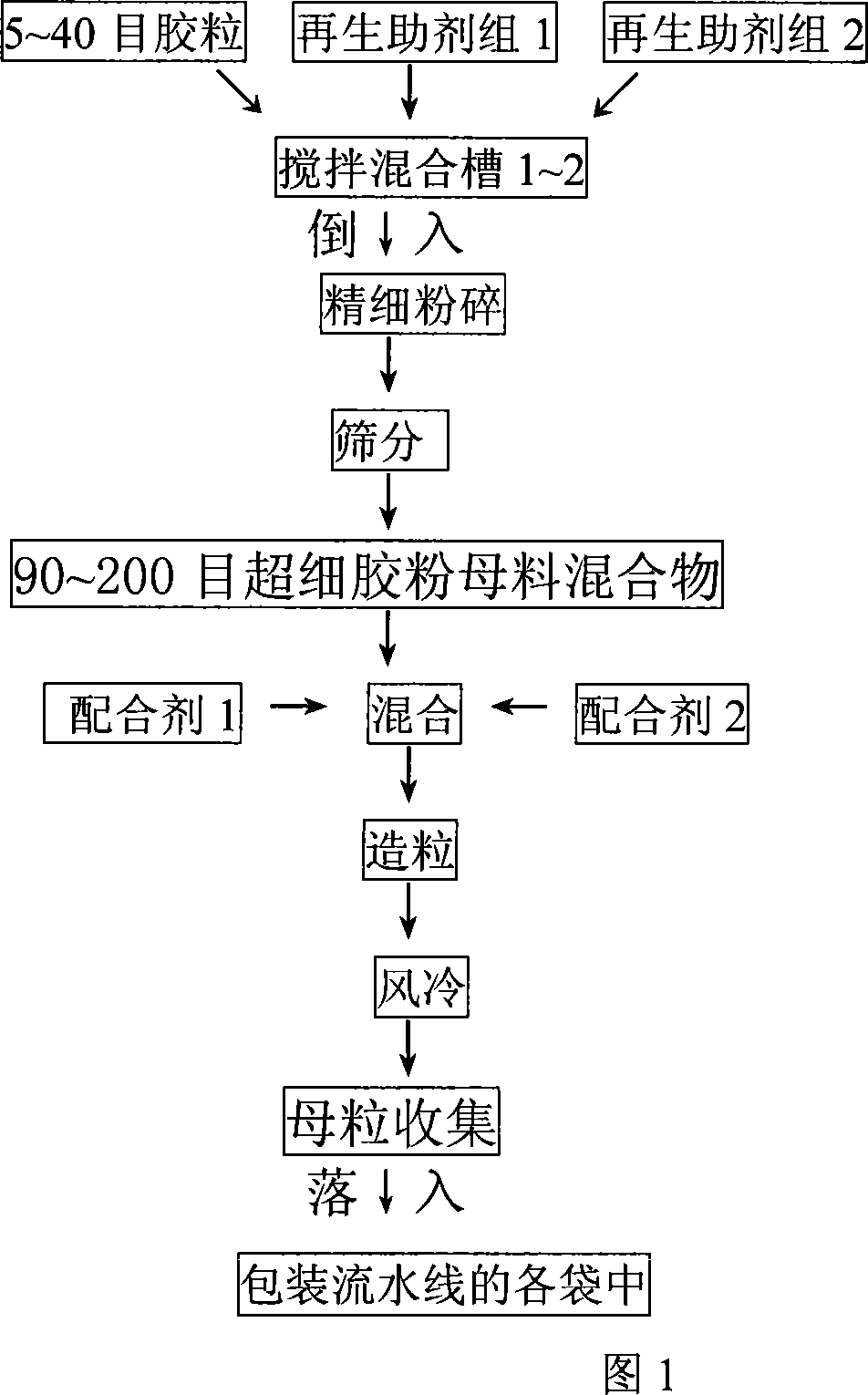

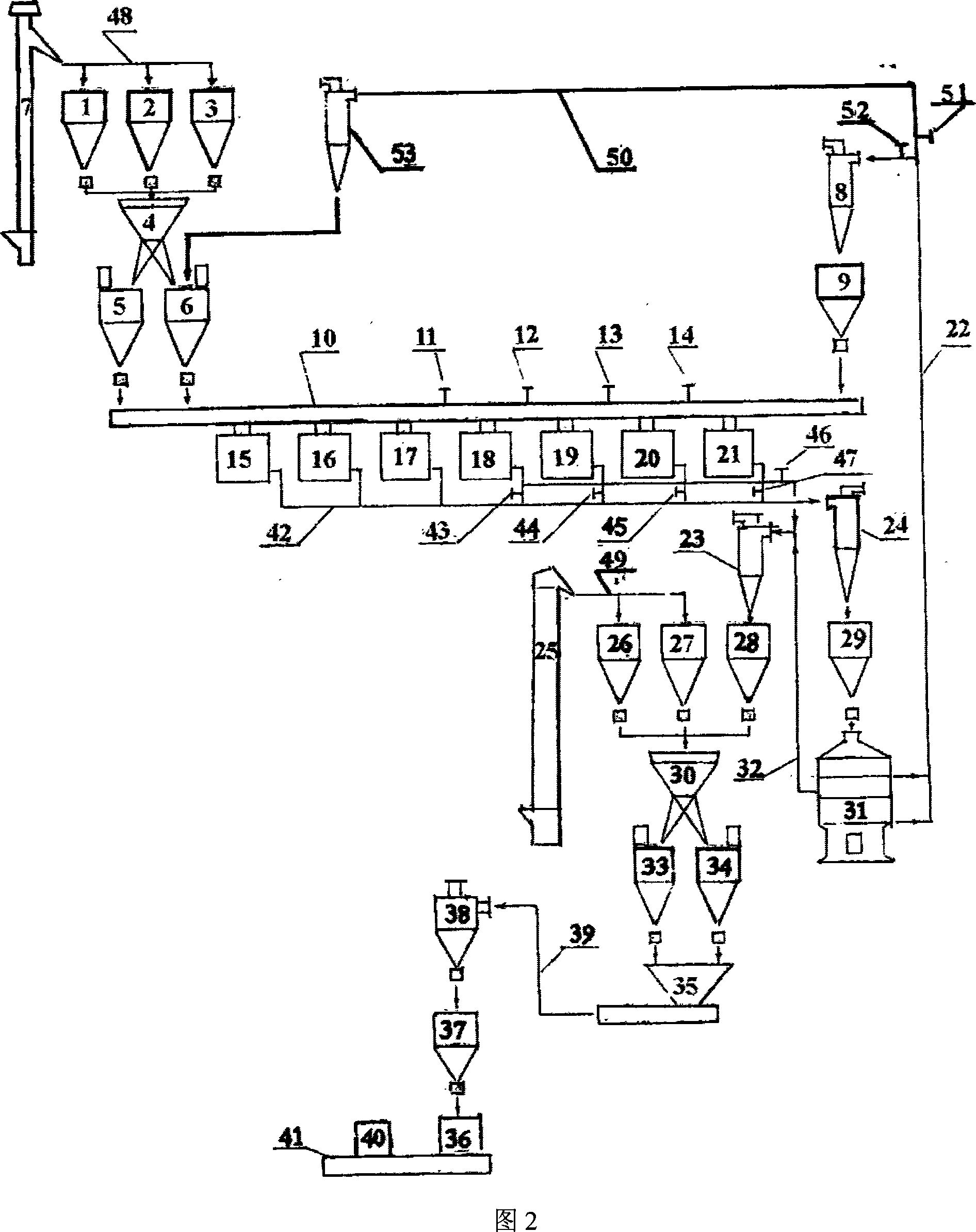

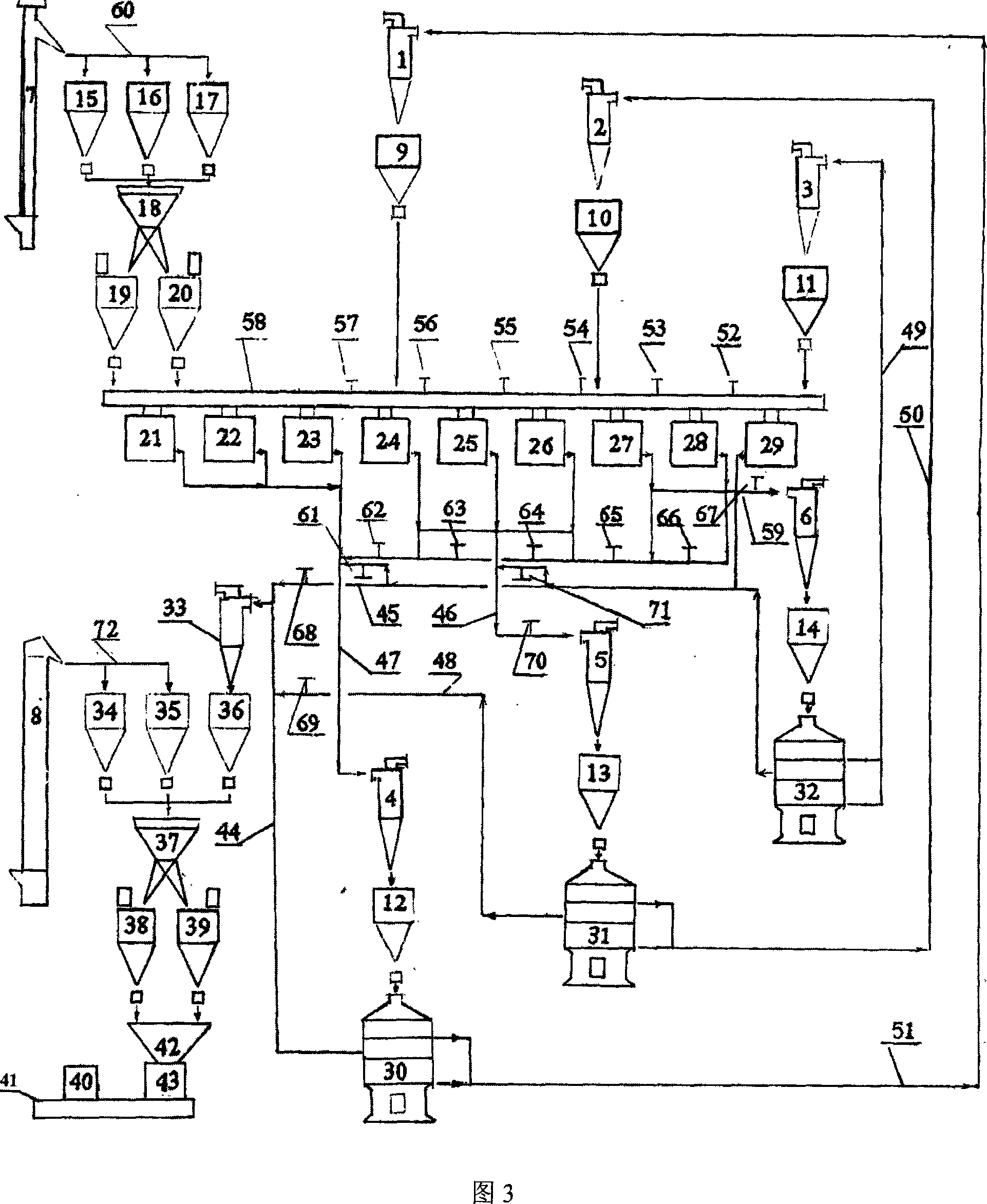

Method used

Image

Examples

Embodiment 1

[0191] Weigh 100 parts of old discarded elastic body particles with a particle size of 20 to 30 mesh radial tire granules, and weigh polyethylene (or / and polypropylene) plastics (about 30×100) separated from Tetra Pak aluminum-plastic composite waste paper. 10 parts of film strips, weighed from powder auxiliary materials:

[0192] 60 parts of carbon-type solidified products of about 5 mesh to about 20 mesh obtained by dry distillation of waste tires,

[0193] Alkali mud (discarded from soda ash plant, pH > 9, about 10 mesh to about 20 mesh, water content 30%, calculated on a dry basis) 10 parts,

[0194] Bentonite (about 10 mesh to about 20 mesh) 5 parts,

[0195] Paper short fiber slag and sludge (discarded from the water purification section of recycled paper mills, pH = 6, water content 40%, about 5 mesh, on a dry basis) 10 parts,

[0196] 85 parts of regenerative aid group; the pH of this regenerative aid group system is 7-9, and has pH buffering property;

[0197] Put ...

Embodiment 2

[0213] Weigh 5 parts of waste rubber shoe rubber particles with a particle size of 20-30 meshes of old discarded elastic body, and 100 parts of film strips (about 30×100) that are initially crushed from agricultural waste polyethylene plastic mulch; weigh powder Accessories:

[0214] 10 parts of vermiculite particles after calcining (about 10 mesh to about 20 mesh),

[0215] Bentonite (about 10 mesh to about 20 mesh) 100 parts,

[0216] Salt mud granules (PH > 9 10-20 mesh discharged from the chlor-alkali plant, water content 30%, on a dry basis) 10 parts,

[0217] Sepiolite (about 10 mesh to about 20 mesh) 10 parts,

[0218] 10 parts of strontium slag (about 10 mesh to about 20 mesh) discharged from the strontium salt factory,

[0219] Paper short fiber slag sludge (about 5 mesh PH=6 water content 40% from the water purification section of the recycled paper factory, calculated on a dry basis) 50 parts,

[0220] Plant husks, leaves, roots, stems, straws, stalks, cores, sk...

Embodiment 3

[0231] Take by weight respectively 50 parts of miscellaneous waste acrylonitrile-butadiene rubber granules whose particle size is about 5 orders, and 50 parts of crumbs (about 5 orders) that are coarsely broken into by agricultural waste polyvinyl chloride plastic pipes; Take from powder accessories:

[0232] 12 parts of variegated material sludge filter cake (moisture content <50%, filter cake diameter <60cm, calculated on dry basis) discharged from printing and dyeing or pigment factories,

[0233] 100 parts of fiber-containing sludge filter cake (moisture content <70%, filter cake diameter <60cm, calculated on dry basis) discharged from paper mills,

[0234] Silica composite gypsum filter cake (water content7, filter cake diameter<60cm, on a dry basis) 18 parts,

[0235] (Discarded from the chlor-alkali plant) 100 parts of salt mud block (water content<50%, PH<11 block diameter<5cm, calculated on dry basis),

[0236] Carboxymethylcellulose sodium 1 part,

[0237] 231 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com