Flyash brick transfer device

A conveying device, a technology for fly ash bricks, applied in the directions of conveyors, transportation and packaging, ceramic molding machines, etc., can solve the problems of unstable production quality, many transportation vehicles, and high costs, achieving compact structure and saving human resources. , the effect of investment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

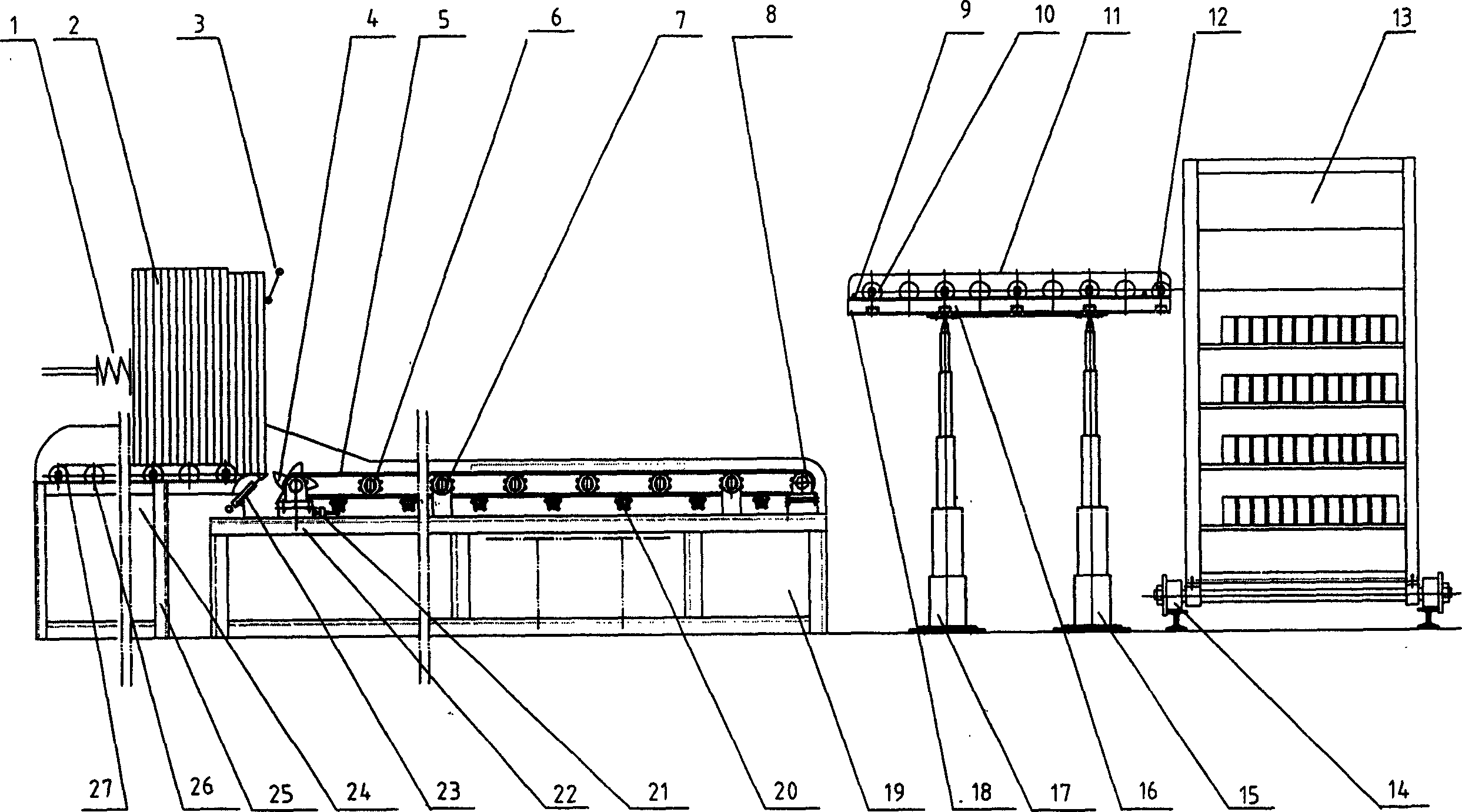

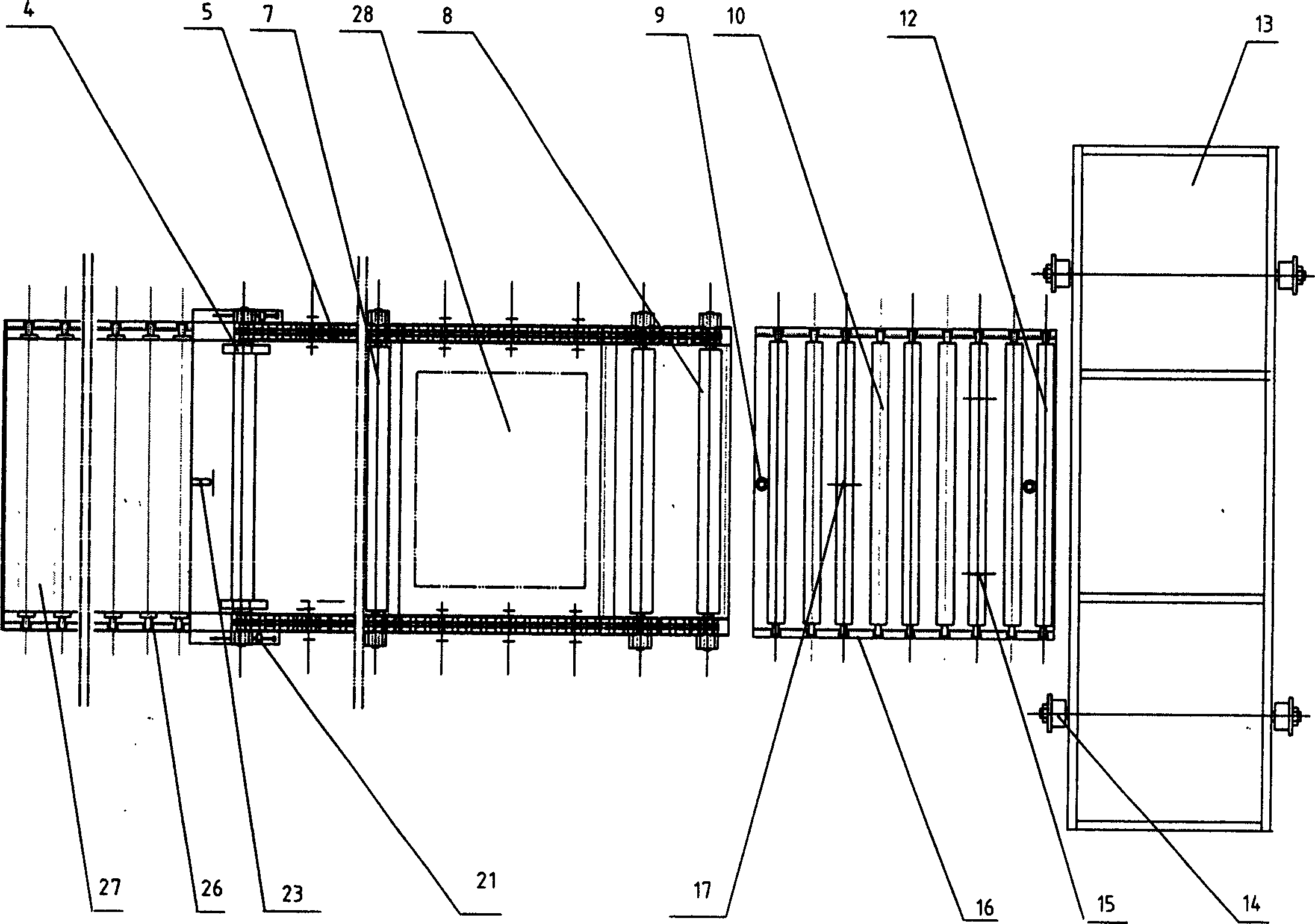

[0011] according to Figure 1-2 The specific structure of the present invention will be described in detail. The device includes a conveyor 19 installed below the mold box (not shown in the figure) of the fly ash brick forming machine, a mold table 28 both sides, a brick frame car 13, and a conveyor 19 arranged between the conveyor 19 and the brick frame car 13. 18 pieces of automatic lifting and translation racking machine. The specifications of each component should be determined according to the requirements of the bricks or blocks processed by the conveying forming machine. Wherein the conveyor 19 is supported by two parallel chain or belt conveyor belts 5 supported by the main electric roller 8 with the driving wheel, the auxiliary electric roller 7 and the tension shaft with the driven wheel and the star wheel 4 and its The limit baffle 6 assembled on the frame body 22 constitutes. Above-mentioned drive wheel and driven wheel should adopt sprocket wheel or pulley acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com