Autoclaved flyash-lime brick and manufacturing method thereof

A technology for autoclaved fly ash bricks and a manufacturing method, which is applied in the field of building materials, can solve problems such as large amount of dust, and achieve the effects of saving production costs, improving production environment and saving steam costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

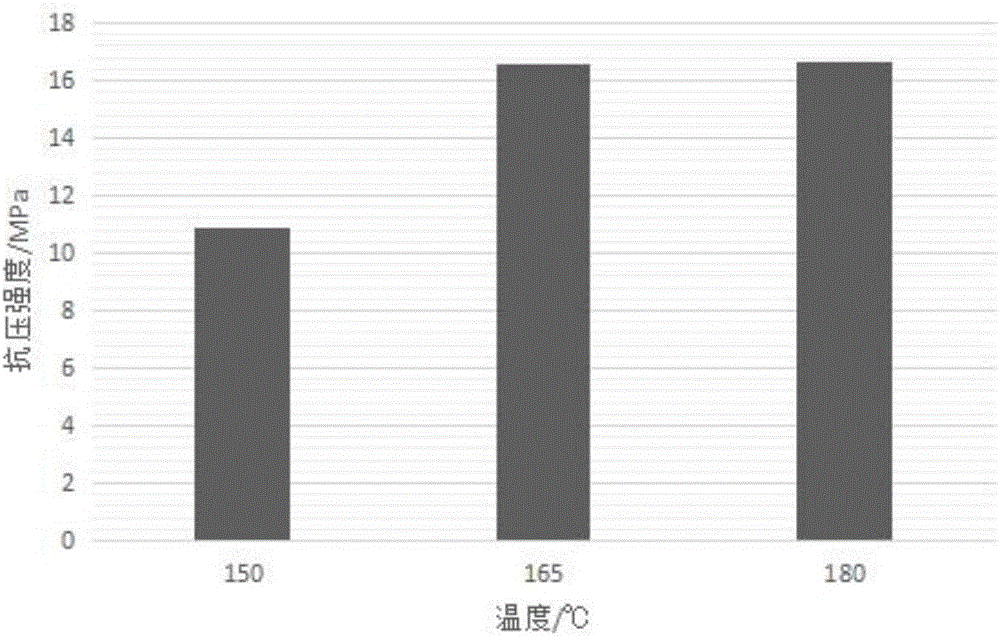

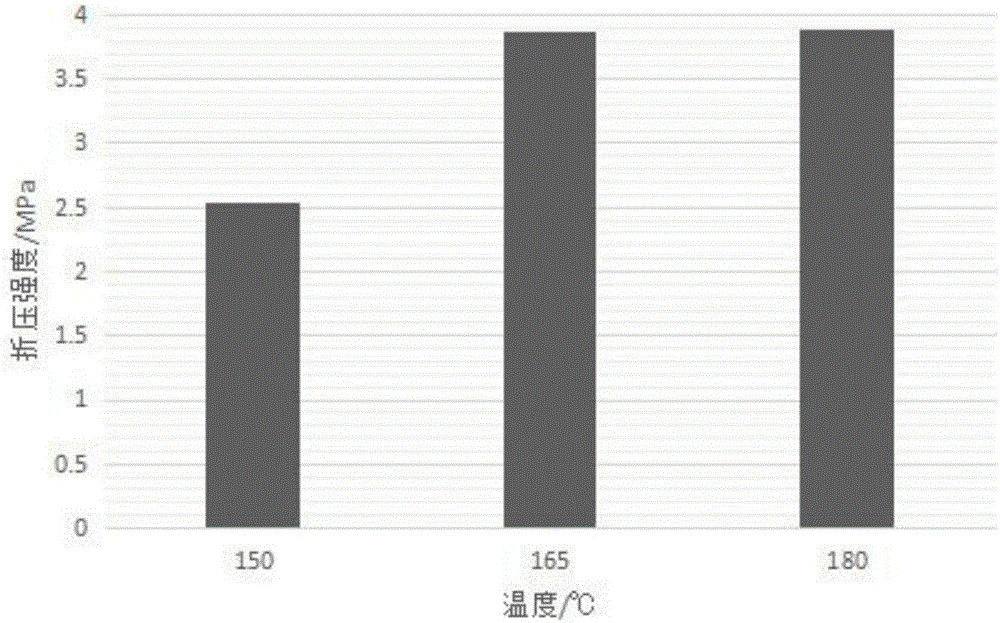

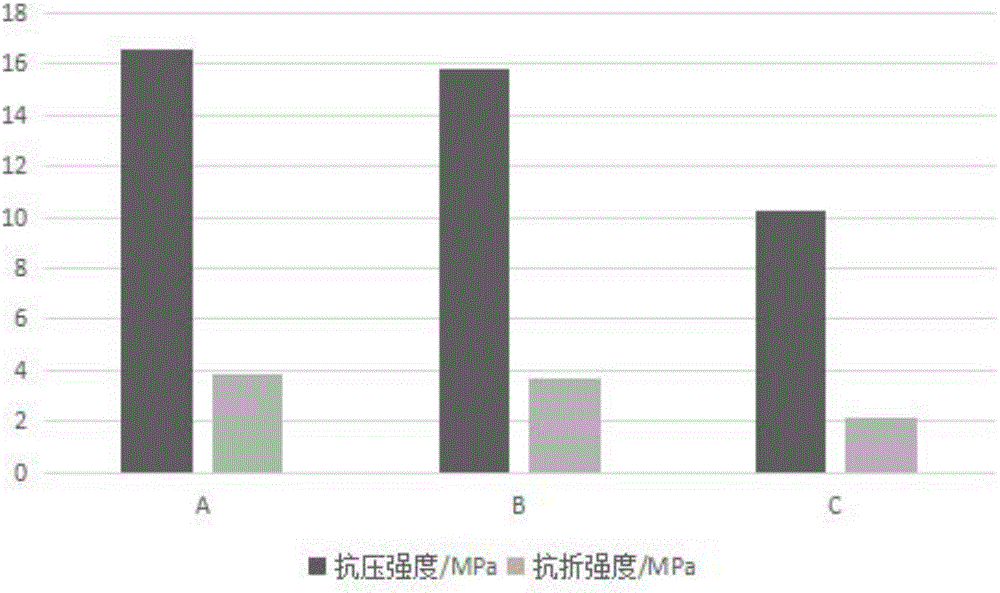

Embodiment 1

[0041] The autoclaved fly ash brick in this embodiment includes the following raw materials in weight percentage: 5% of coal gasification slag, 15% of fly ash, 50% of aggregate, 20% of carbide slag, and 10% of phosphogypsum.

[0042] According to the percentage by weight of the raw materials of this embodiment, the manufacture method of the autoclaved fly ash brick comprises the following steps:

[0043] S1. Weigh each raw material according to the percentage by weight of the raw material;

[0044] S2. Evenly measure the coal gasification slag, aggregate, calcium carbide slag and phosphogypsum into the feeding hopper through the belt, then add the materials and fly ash in the feeding hopper to the mixer at the same time, mix and stir evenly, and the stirring time is 3 minutes ;

[0045] S3. Send the uniformly stirred material in step S2 into the digestion chamber, store and digest for 2 hours, then send it to the powder mixer, and then send it to the automatic hydraulic brick...

Embodiment 2

[0047] The autoclaved fly ash brick in this embodiment includes the following raw materials in weight percentage: 5% of coal gasification slag, 15% of fly ash, 50% of aggregate, 20% of carbide slag, and 10% of phosphogypsum.

[0048] According to the percentage by weight of the raw materials of this embodiment, the manufacture method of the autoclaved fly ash brick comprises the following steps:

[0049] S1. Weigh each raw material according to the percentage by weight of the raw material;

[0050] S2. Evenly measure the coal gasification slag, aggregate, calcium carbide slag and phosphogypsum into the feeding hopper through the belt, then add the materials and fly ash in the feeding hopper to the mixer at the same time, mix and stir evenly, and the stirring time is 3 minutes ;

[0051] S3. Send the uniformly stirred material in step S2 into the digestion bin, store and digest for 2 hours, then send it to the powder mixer, and then send it to the automatic hydraulic brick mac...

Embodiment 3

[0053] The autoclaved fly ash brick in this embodiment includes the following raw materials in weight percentage: 5% of coal gasification slag, 15% of fly ash, 50% of aggregate, 20% of carbide slag, and 10% of phosphogypsum.

[0054] According to the percentage by weight of the raw materials of this embodiment, the manufacture method of the autoclaved fly ash brick comprises the following steps:

[0055] S1. Weigh each raw material according to the percentage by weight of the raw material;

[0056] S2. Evenly measure the coal gasification slag, aggregate, calcium carbide slag and phosphogypsum into the feeding hopper through the belt, then add the materials and fly ash in the feeding hopper to the mixer at the same time, mix and stir evenly, and the stirring time is 3 minutes ;

[0057]S3. Send the uniformly stirred material in step S2 into the digestion chamber, store and digest for 2 hours, then send it to the powder mixer, and then send it to the automatic hydraulic brick ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com