Fly ash brick unbaking shaping method

A technology of fly ash bricks and fly ash, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of large equipment investment, low production efficiency, high operating cost, etc., and achieve reasonable process design , less equipment and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

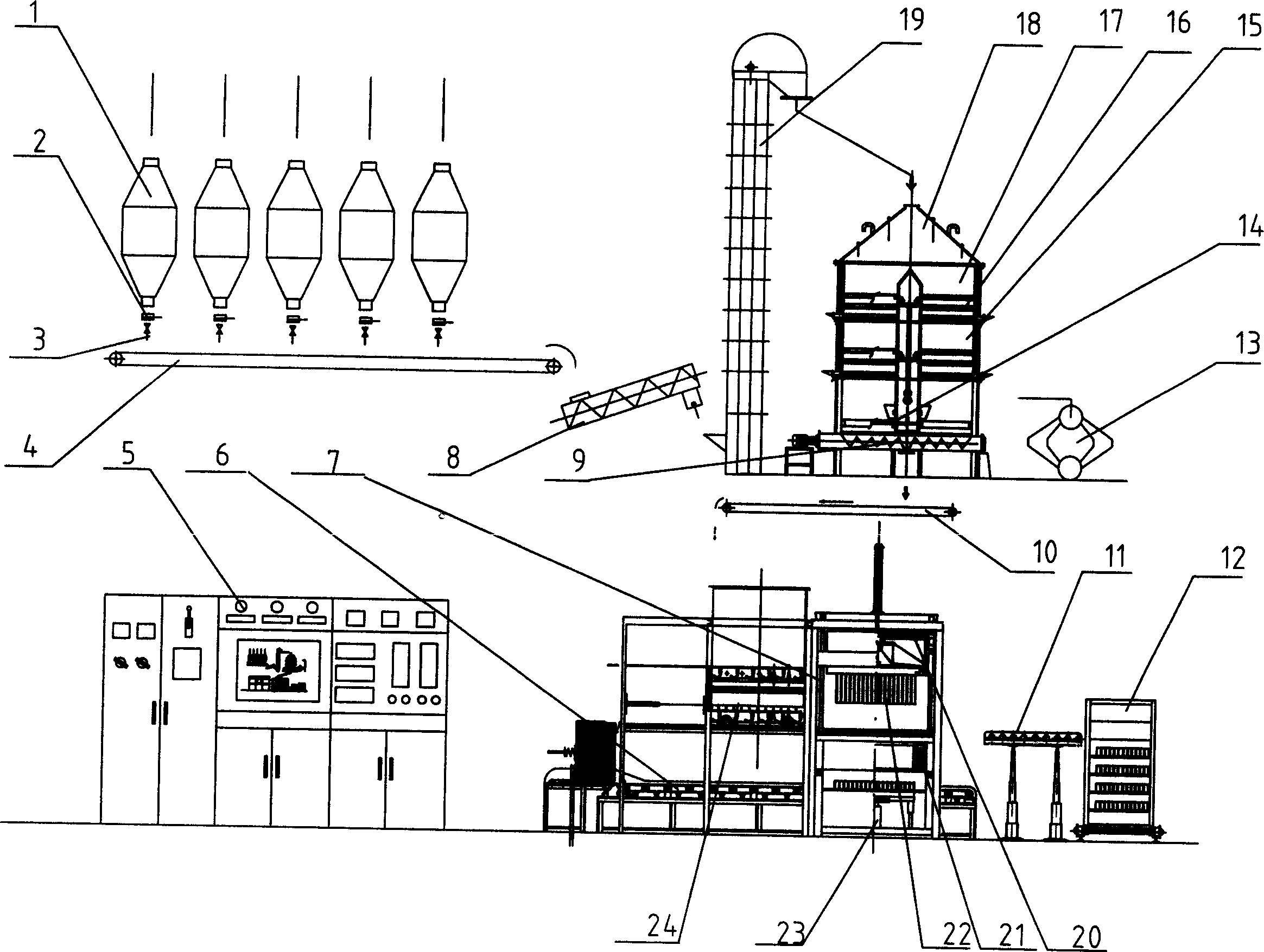

[0023] according to figure 1 Specific embodiments of the present invention will be described in detail. The raw materials used in the molding method are industrial waste fly ash, slag, carbide slag and auxiliary materials such as phosphogypsum and cement. The main considerations for the selection of raw materials are: 1. Make full use of the characteristics that fly ash can only exert its potential energy after being excited; 2. Blend the corresponding proportion of slag and carbide slag that are closely related to fly ash and can coordinate potential energy (papermaking waste liquid or quicklime), phosphogypsum that has a coordinating effect on alkaline excitation (leftovers from chemical fertilizer plants) and an appropriate amount of cement that has both mastic and excitation effects, and the ingredients are properly mixed to make the loose particles at a certain temperature , humidity, and pressure conditions, repeated activation and homogenization, and then a strong acti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com