Building method for controlling temperature cracks of masonry

A body temperature and building technology, which is applied in the construction, building structure, building material processing and other directions, can solve the problems of large impact, negative impact, and reduced wall quality when the project is put into production, achieve good social benefits and reduce cracks , the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

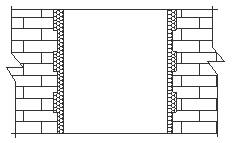

[0026] Accompanying drawing is a kind of specific embodiment of the present invention.

[0027] The construction method of controlling the temperature crack of masonry of the present invention is made up of the following steps:

[0028] A. Soak the bricks with water before masonry to ensure that the moisture content of the fly ash bricks is 8-12%, or the water absorption depth around the section of the fly ash bricks is 15-20mm;

[0029] B positioning and laying out, laying bricks;

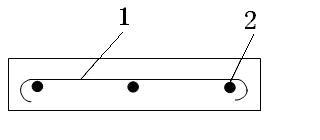

[0030] C brick masonry construction: setting control joints and reinforced concrete slab strips on the brick masonry to control the damage to the masonry caused by temperature changes and drying shrinkage of materials;

[0031] D Settle and maintain the wall after the masonry is completed.

[0032] The building method of the control masonry temperature crack of the present invention is specifically as follows:

[0033] 1. Aiming at the problem of insufficient soaking of bricks before masonry

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com