Crack-resisting masonry mortar for air-entrapping brick wall body, prepared from desulfurization gypsum powder

A technology for desulfurized gypsum powder and masonry mortar is applied in the field of crack-resistant masonry mortar, which can solve the problems of unfavorable living environment, large shrinkage, unstable performance, etc., and achieves cheap and easy-to-obtain raw materials, high crack resistance, and low shrinkage. deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

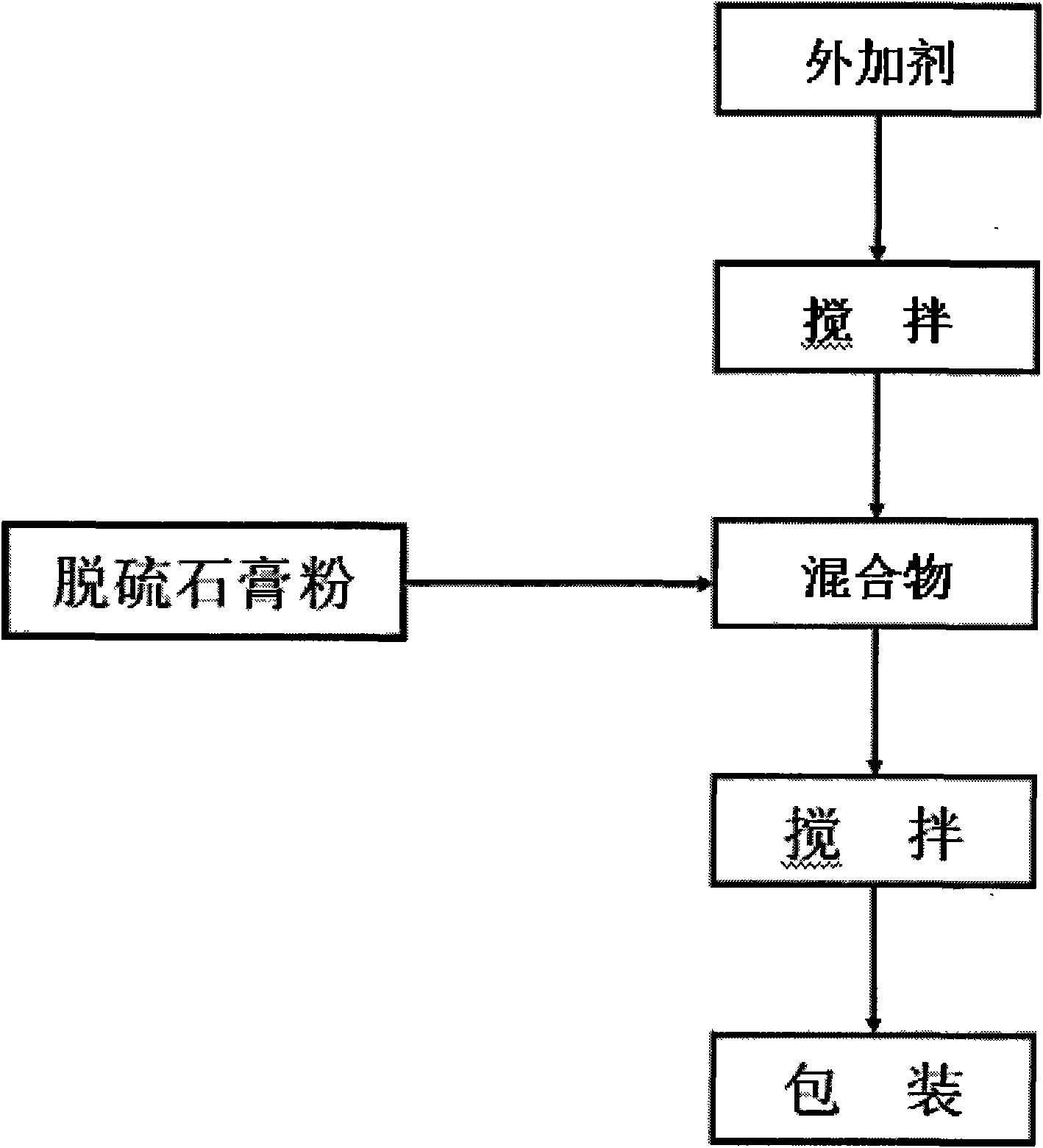

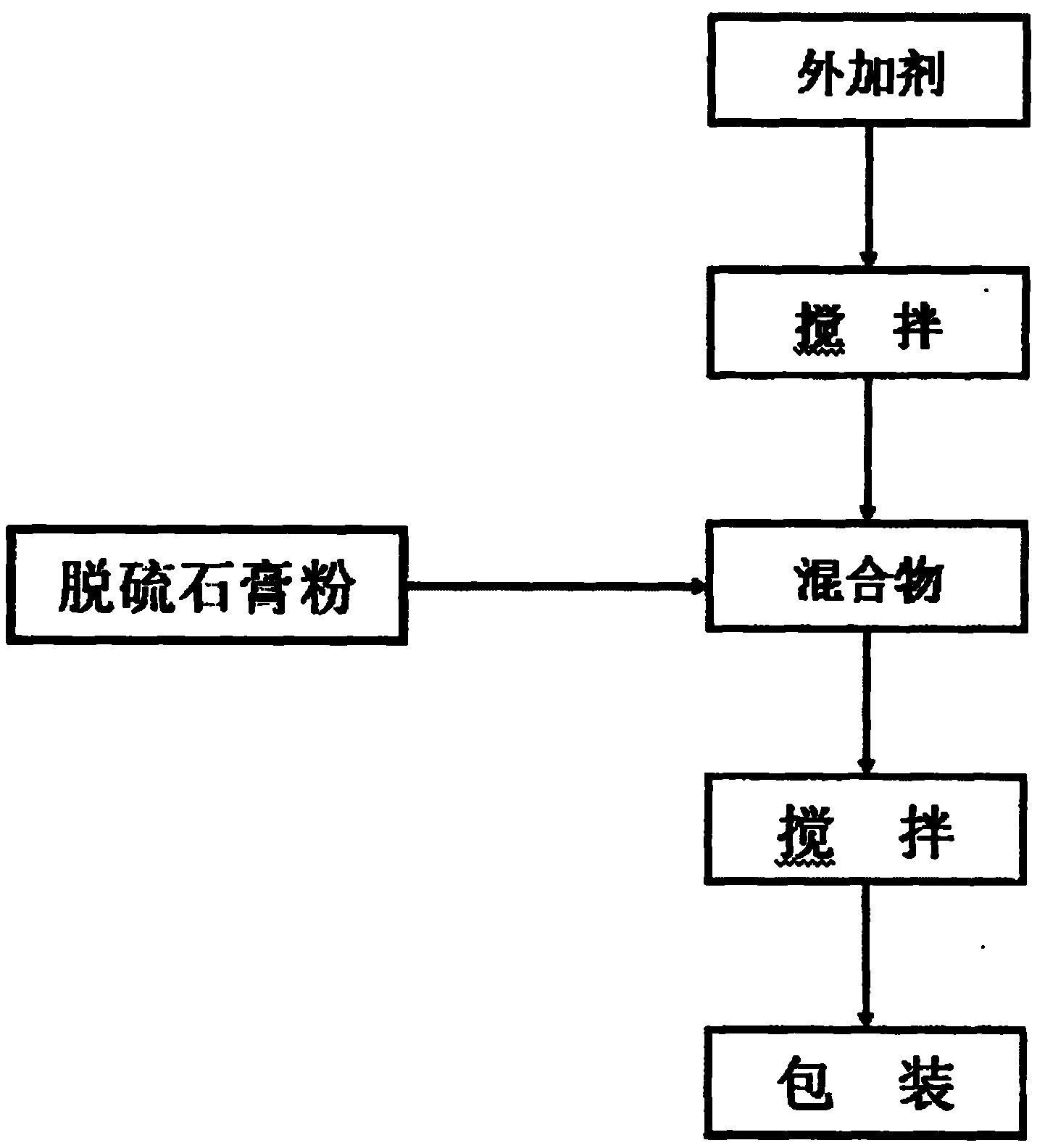

Method used

Image

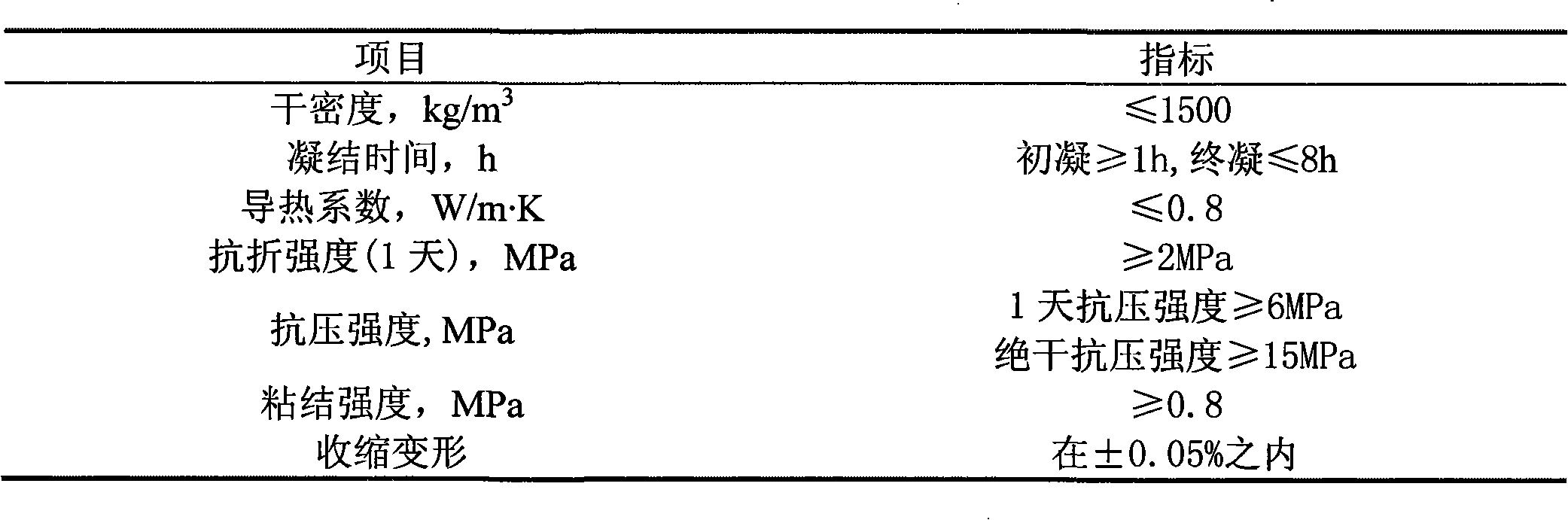

Examples

Embodiment 1

[0023] By weight, take 50 parts of desulfurized gypsum powder, 0.1 part of tartaric acid, 0.1 part of methyl cellulose ether, 1 part of ash calcium powder, 0.2 part of 500 μm lignin fiber, and 10 parts of slag with a fineness of 325 mesh, and put them into the mixer. Mix for 20 minutes, the mixer speed is 60 rpm, and then mix with 18.6 parts of fine river sand with a fineness of 40 mesh and 20 parts of fine river sand with a fineness of 80 mesh. The mixing time is 10 minutes, and the stirring speed is 60 rpm. Obtain 100 parts of anti-crack masonry mortar for finished aerated brick wall. Embodiment two:

Embodiment 2

[0024] By weight, take 48 parts of desulfurized gypsum powder, 0.1 part of citric acid, 2 parts of bentonite, 3 parts of Portland cement, 0.2 part of 500 μm lignin fiber, and 10 parts of slag with a fineness of 325 mesh, put them into a mixer, and mix for 20 Minutes, stirring time 60 rpm, and then mixed with 36.7 parts of fine river sand with a fineness of 40 mesh, mixing time 10 minutes, stirring speed 60 rpm, to obtain crack-resistant masonry mortar for finished aerated brick walls 100 copies.

Embodiment 3

[0026] By weight, take 45.5 parts of desulfurized gypsum powder, 0.3 part of sodium polyphosphate, 0.1 part of hydroxypropyl methylcellulose ether, 2 parts of ash calcium powder, 0.2 part of 40 μm lignin fiber, and fly ash of 325 mesh fineness 18 parts, put into the mixer, mix for 20 minutes, the stirring time is 60 rpm, and then mix with 33.9 parts of fine river sand with a fineness of 80 mesh, the mixing time is 10 minutes, and the stirring speed is 60 rpm to obtain the finished product 100 parts of anti-crack masonry mortar for brick wall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com