Non-fired and non-steamed fly ash brick produced by using CFBC desulphurization residues and preparation process thereof

A technology of fly ash bricks and desulfurization ash, which is applied in the field of building materials, can solve the problems of large energy consumption, re-pollution of sulfur dioxide, low utilization rate of desulfurization ash, etc., and achieves the effects of solving low utilization rate, easy to popularize and use, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Components and proportions: CFBC desulfurization ash 54%, bottom slag 25%, cement 6%, quicklime 10%, gypsum 5%.

[0014] Process: Mix CFBC desulfurization ash, bottom slag, cement, lime, gypsum and other components, add 13% (mass ratio) of water, stir for 2 minutes to make it uniform, then press and shape with 18MPa pressure and put it in a curing box for curing In 28 days, MU15 fly ash bricks are ready.

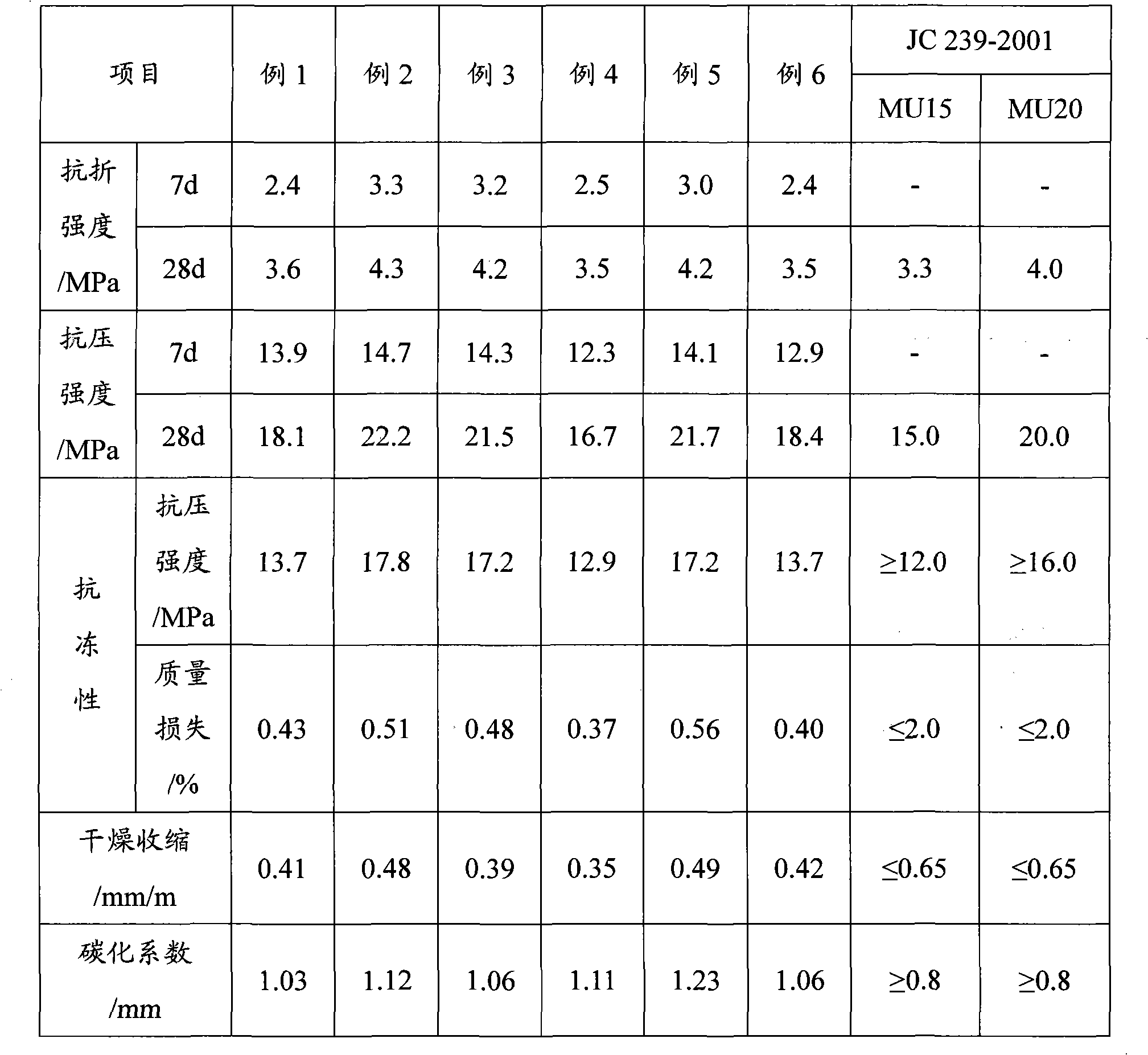

[0015] Effect: Appearance size and deviation meet the requirements of superior product (A), the test block has no obvious color difference, and other performance indicators are shown in Table 1.

Embodiment 2

[0017] Components and proportions: CFBC desulfurization ash 57%, bottom slag 20%, cement 8%, quicklime 12%, gypsum 3%.

[0018] Process: Mix CFBC desulfurization ash, bottom slag, cement, lime, gypsum and other components, add 15% (mass ratio) of water, stir for 2 minutes to make it uniform, and then press and shape with 20MPa pressure and put it in a curing box for curing In 28 days, MU20 fly ash bricks are ready.

[0019] Effect: Appearance size and deviation meet the requirements of superior product (A), the test block has no obvious color difference, and other performance indicators are shown in Table 1.

Embodiment 3

[0021] Components and proportions: 70% CFBC desulfurization ash, 10% bottom slag, 6% cement, 10% quicklime, and 4% gypsum.

[0022] Process: Mix CFBC desulfurization ash, furnace bottom slag, cement clinker, lime, gypsum and other components, add 18% water (mass ratio), stir for 2 minutes to make it uniform, and then press and shape with 22MPa pressure and put it in the curing box After curing for 28 days, it will become MU20 fly ash brick.

[0023] Effect: Appearance size and deviation meet the requirements of superior product (A), the test block has no obvious color difference, and other performance indicators are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com