Synthesis method of self-assembled Ni3S2 nano-sheet

A synthesis method and self-assembly technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of catalytic activity, catalytic stability, and use range gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) First, the 1cm×2cm nickel foam was ultrasonically cleaned at 70W in acetone and 3mol / L HCl solution for 8 minutes, then washed with deionized water and absolute ethanol, and dried at room temperature;

[0019] 2) Next, put the dried nickel foam into a 50mL high-temperature and high-pressure reactor with a polytetrafluoroethylene liner, then add 5mL of thiourea solution with a concentration of 1.445mmol / L, and add 0.275-0.363g of polyethylene Pyrrolidone (PVP) morphology control agent, the reactor is sealed, placed in an oven at 130 ° C for 10 h;

[0020] 3) After the reaction is finished, after naturally cooling to room temperature, take out the nickel foam, and rinse repeatedly with water and absolute ethanol respectively;

[0021] 4) Finally, put the rinsed nickel foam into a vacuum oven to dry at room temperature to obtain self-assembled Ni 3 S 2 Nanosheet array self-supporting electrodes.

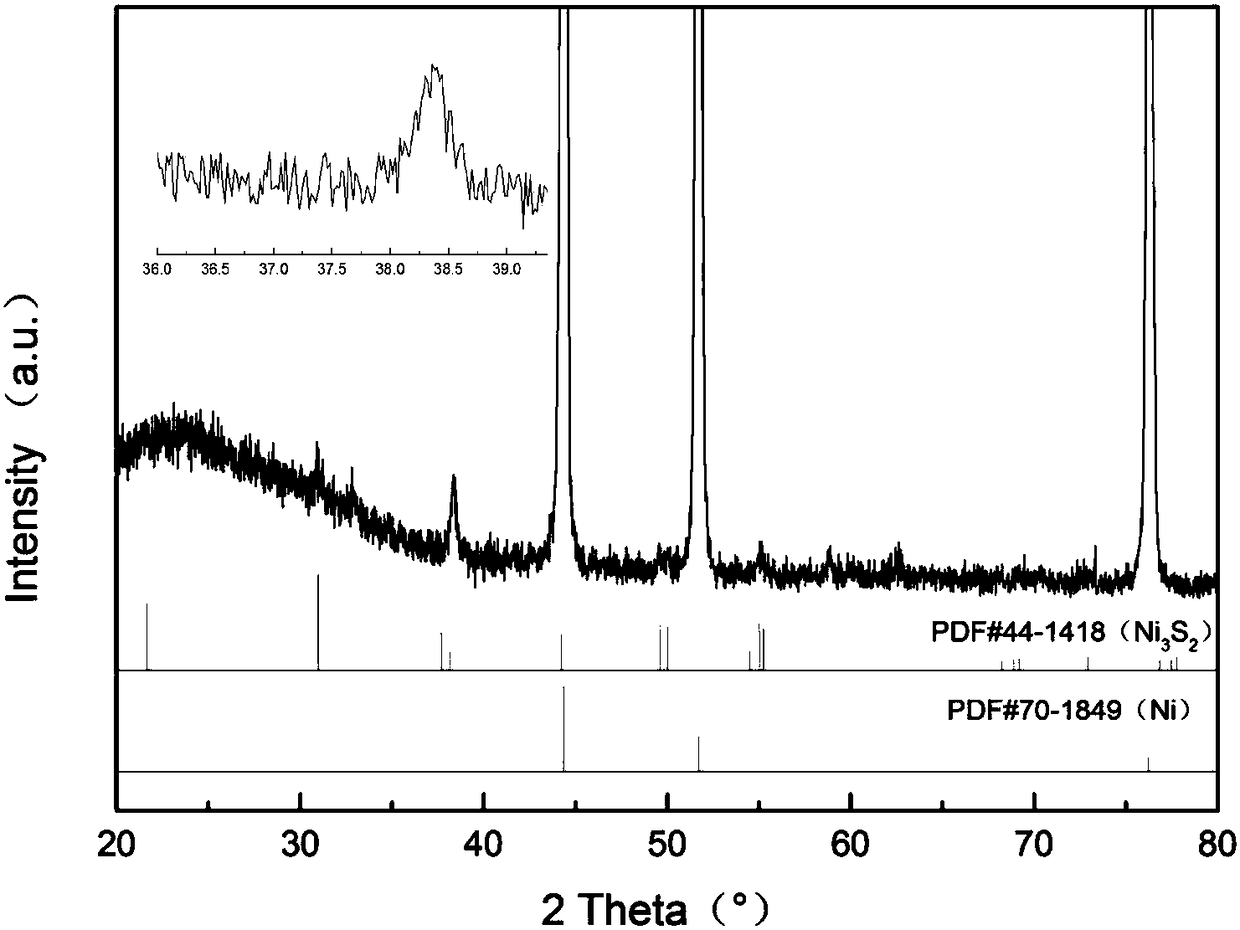

[0022] Depend on figure 1 It can be seen that the sample prepared in ...

Embodiment 2

[0024] 1) First, the 1cm×2cm nickel foam was ultrasonically cleaned at 80W in acetone and 3mol / L HCl solution for 5 minutes, then washed with deionized water and absolute ethanol, and dried at room temperature;

[0025] 2) Next, put the dried nickel foam into a 50mL high-temperature and high-pressure reactor with a polytetrafluoroethylene lining, then add 8mL of 1.445mmol / L thiourea solution, and add 0.2-0.264g of polyethylene Pyrrolidone (PVP) morphology control agent, the reactor is sealed, placed in an oven at 140 ° C for 9 hours;

[0026] 3) After the reaction is finished, after naturally cooling to room temperature, take out the nickel foam, and rinse repeatedly with water and absolute ethanol respectively;

[0027] 4) Finally, put the rinsed nickel foam into a vacuum oven to dry at room temperature to obtain self-assembled Ni 3 S 2 Nanosheet array self-supporting electrodes.

[0028] figure 2 It can be seen that a self-assembled Ni prepared in this example 3 S 2 N...

Embodiment 3

[0030] 1) First, the 1cm×2cm nickel foam was ultrasonically cleaned at 80W in acetone and 3mol / L HCl solution for 10min, then washed with deionized water and absolute ethanol, and dried at room temperature;

[0031] 2) Next, put the dried nickel foam into a 50mL high-temperature and high-pressure reactor with a polytetrafluoroethylene liner, then add 10mL of 1.445mmol / L thiourea solution, and add 0.15-0.198g of polyethylene Pyrrolidone (PVP) morphology control agent, the reaction kettle is sealed, placed in an oven at 150 ° C for 8 hours;

[0032] 3) After the reaction is finished, after naturally cooling to room temperature, take out the nickel foam, and rinse repeatedly with water and absolute ethanol respectively;

[0033] 4) Finally, put the rinsed nickel foam into a vacuum oven to dry at room temperature to obtain self-assembled Ni 3 S 2 Nanosheet array self-supporting electrodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com