Ternary positive electrode material of high-nickel monocrystal-like lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problems of reduced material energy density, irreversible capacity loss, etc., and achieve improved processing performance, less impurities, and complete and sufficient reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

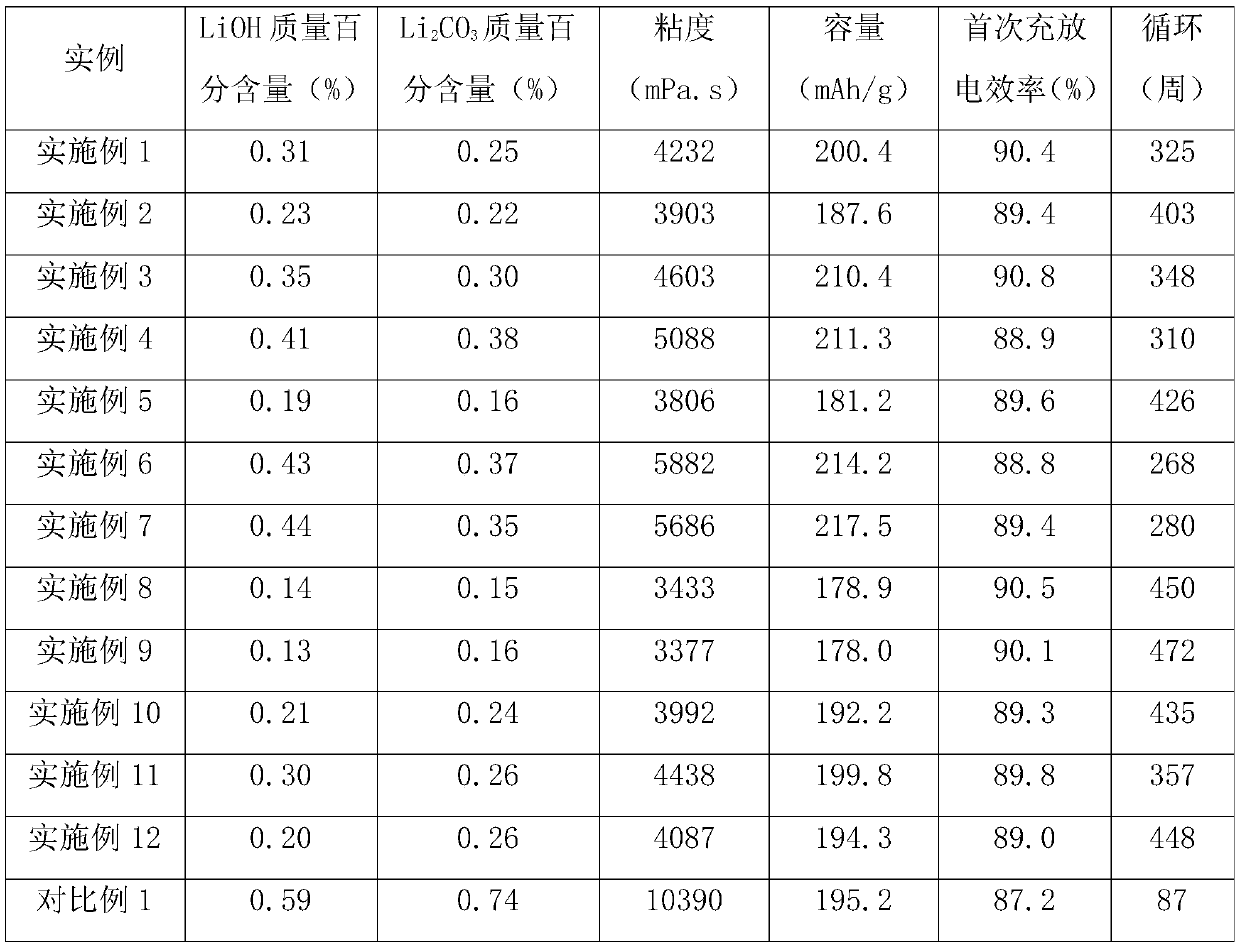

Embodiment 1

[0030] Synthesis of precursors:

[0031] Mix nickel sulfate, cobalt sulfate, manganese sulfate and magnesium sulfate according to the element molar ratio of Ni:Co:Mn:Mg=0.80:0.10:0.097:0.003 to form a metal ion mixture with a metal ion concentration of 2.5mol / L; 5mol / L NaOH solution; prepare ammonia water with a concentration of 6mol / L. Pass N 2 While protecting, add the above-mentioned metal ion mixture, NaOH solution, and ammonia solution into the reactor at a flow ratio of 1:3:0.2, and keep the pH value in the reactor at 11.6. After the reaction is completed, the obtained precipitate is filtered, washed, dried, and passed through a 300-mesh sieve to obtain a precursor.

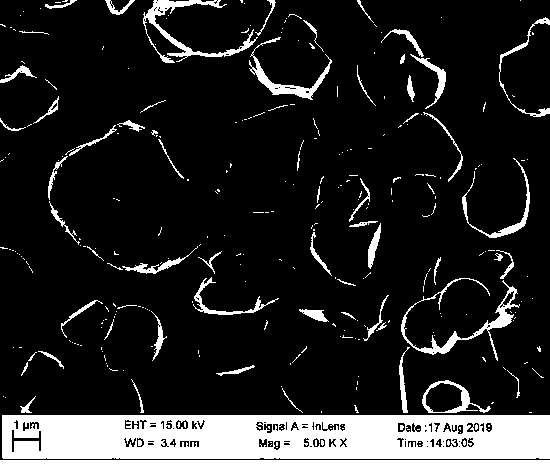

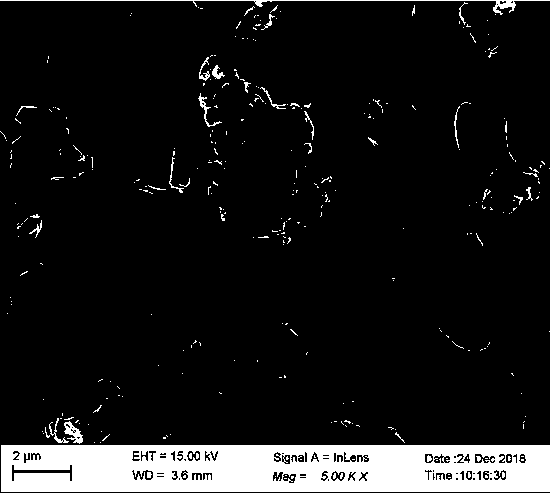

[0032] Synthesized precursor Ni 0.80 co 0.10 mn 0.097 Mg 0.003 (OH) 2 The particle size is: D10: 1.2 μm; D50: 3.0 μm; D90: 5.5 μm, and the particle size distribution conforms to the normal distribution.

[0033] Raw material pretreatment:

[0034] The precursor Ni prepared above 0.80 co 0.10 mn ...

Embodiment 2

[0048] Synthesis of precursors:

[0049] Mix nickel nitrate, cobalt nitrate, manganese nitrate and aluminum nitrate according to the element molar ratio of Ni:Co:Mn:Al=0.70:0.15:0.148:0.002 to form a metal ion mixture, the metal ion concentration is 3.0mol / L; 4.5mol / L NaOH solution; prepare ammonia water with a concentration of 8mol / L. Pass N 2 While protecting, add the above-mentioned metal ion mixture, NaOH solution, and ammonia solution into the reactor at a flow ratio of 1:6:2, and keep the pH value in the reactor at 11.3. After the reaction is completed, the obtained precipitate is filtered, washed, dried, and passed through a 300-mesh sieve to obtain a precursor.

[0050] Synthesized precursor Ni 0.70 co 0.15 mn 0.148 al 0.002 (OH) 2 The particle size is: D10: 1.0 μm; D50: 3.1 μm; D90: 5.4 μm, and the particle size distribution conforms to the normal distribution.

[0051] Raw material pretreatment:

[0052] The precursor Ni prepared above 0.70 co 0.15 mn 0.1...

Embodiment 3

[0061] Synthesis of precursors:

[0062] Nickel chloride, cobalt chloride, manganese chloride and zirconium nitrate are prepared in the molar ratio of Ni:Co:Mn:Zr=0.83:0.12:0.047:0.003 to form a metal ion mixture, and the metal ion concentration is 2.5mol / L ; The configuration concentration is 4mol / L NaOH solution; the preparation concentration is 8mol / L ammonia water. Pass N 2 While protecting, add the above-mentioned metal ion mixture, NaOH solution, and ammonia solution into the reactor at a flow ratio of 1:3:2, and keep the pH value in the reactor at 11.8. After the reaction is completed, the obtained precipitate is filtered, washed, dried, and passed through a 300-mesh sieve to obtain a precursor. Synthesized precursor Ni 0.83 co 0.12 mn 0.047 Zr 0.003 (OH) 2 The particle size is: D10: 1.2μm; D50: 3.3μm; D90: 5.6μm, and the particle size distribution conforms to the normal distribution.

[0063] Raw material pretreatment:

[0064] The precursor Ni prepared above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com