Phosphorous-nitrogen-containing polyethylene glycol terephthalate flame retardant copolyester and application of flame retardant copolyester

A technology of ethylene phthalate and terephthalic acid is applied in the field of polymer synthesis of halogen-free flame retardant polymer new materials, which can solve the problem of lack of phosphorus-nitrogen synergistic flame retardant, failure to pass the flame retardant B1 level standard, etc. problem, to achieve the effect of increased compatibility, good washing durability and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

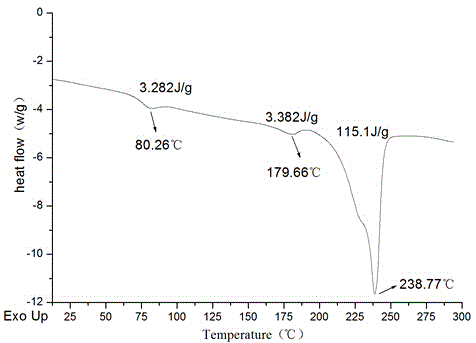

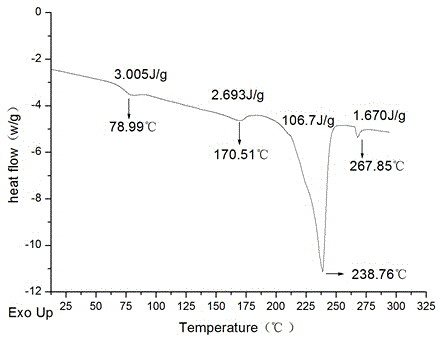

Image

Examples

Embodiment 1

[0037] (1) Mix 68.8 kilograms of ethylene glycol and 166 kilograms of terephthalic acid, add 0.03 kilograms of catalyst antimony trioxide, then evacuate and replace four times with nitrogen, add nitrogen to make the pressure rise to 0.15MPa, and heat up To 195°C, while maintaining the pressure at 0.20MPa, carry out the first esterification reaction, the esterification reaction is 1.0 hour, the esterification rate is 90.3%, and the first esterification product is obtained;

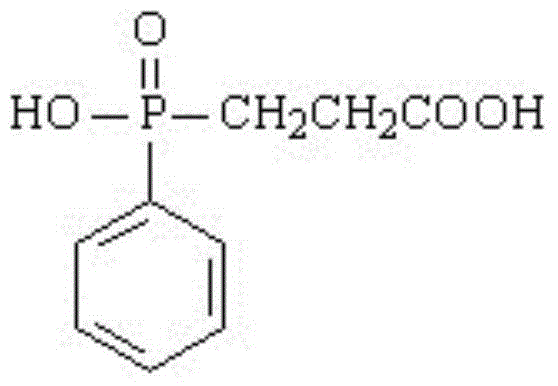

[0038] (2) Mix 21.4 kilograms of ethylene glycol and 42.8 kilograms of 2-carboxyethylphenylphosphinic acid, add 0.007 kilograms of antimony trioxide as a catalyst, then evacuate in turn, replace with nitrogen four times, and pressurize to 0.25MPa , the temperature was raised to 195° C., while the pressure was maintained at 0.30 MPa, and the second esterification reaction was carried out. The esterification reaction was 1.1 hours, and the esterification rate was 65%. When the generated water was close to the ...

Embodiment 2

[0045] (1) Mix 74.5 kilograms of ethylene glycol and 166 kilograms of terephthalic acid, add 0.03 kilograms of catalyst antimony trioxide, then evacuate and replace four times with nitrogen, add nitrogen to make the pressure rise to 0.20 MPa, and raise the temperature To 195°C, while the pressure is maintained at 0.25MPa, carry out the first esterification reaction, the esterification reaction is 1.5 hours, the esterification rate is 91.5%, and the first esterification product is obtained when the generated water is close to the theoretical amount;

[0046] (2) Mix 12.4 kilograms of ethylene glycol and 21.4 kilograms of 2-carboxyethylphenylphosphinic acid, add 0.004 kilograms of catalyst antimony trioxide, then sequentially evacuate and replace with nitrogen for four times, then pressurize to 0.30MPa, The temperature was raised to 195°C while the pressure was maintained at 0.35MPa, and the second esterification reaction was carried out. The esterification reaction lasted for 2....

Embodiment 3

[0055] (1) Mix 80.7 kg of ethylene glycol and 166 kg of terephthalic acid, add 0.03 kg of catalyst antimony trioxide, then evacuate and replace with nitrogen for four times, add nitrogen to make the pressure rise to 0.28 MPa, and heat up To 205°C, while the pressure is maintained at 0.35MPa, the first esterification reaction is carried out, the esterification reaction is 2.7 hours, the esterification rate is controlled at 95.0%, and the first esterification product is obtained when the generated water is close to the theoretical amount;

[0056] (2) Mix 12.4 kilograms of ethylene glycol and 21.4 kilograms of 2-carboxyethylphenylphosphinic acid, add 0.004 kilograms of catalyst antimony trioxide, then evacuate in turn, pressurize to 0.35MPa after four times of nitrogen displacement, The temperature was raised to 200°C, while the pressure was maintained at 0.35MPa, and the second esterification reaction was carried out. The esterification reaction lasted for 2.7 hours, and the est...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com