Boiler capable of preventing vent holes from being blocked

A technology for ventilation holes and boilers, which is applied in the treatment of combustion products, blasting equipment, combustion methods, etc., can solve the problems of affecting the combustion effect of coal, easy to block ventilation holes, and inaccessibility of air, so as to improve stability and service life. , Good inflating effect, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

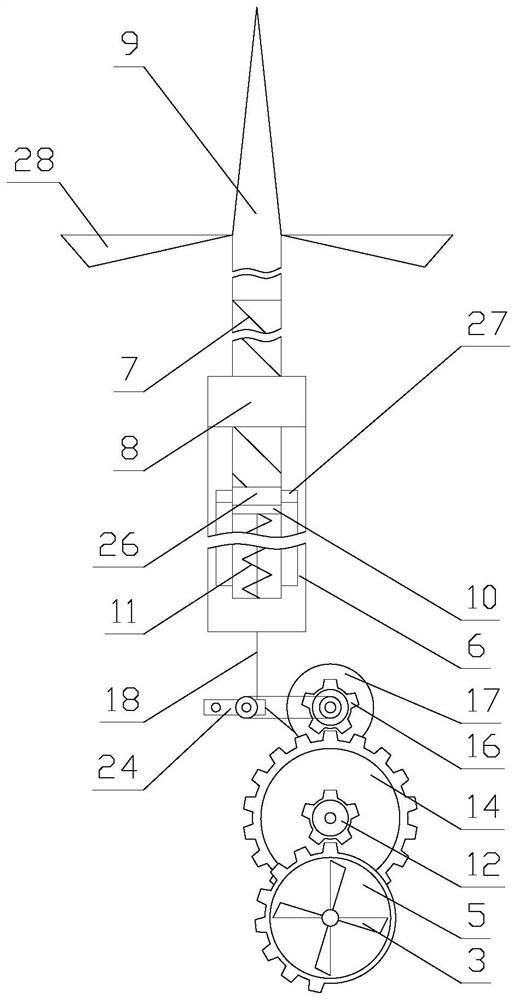

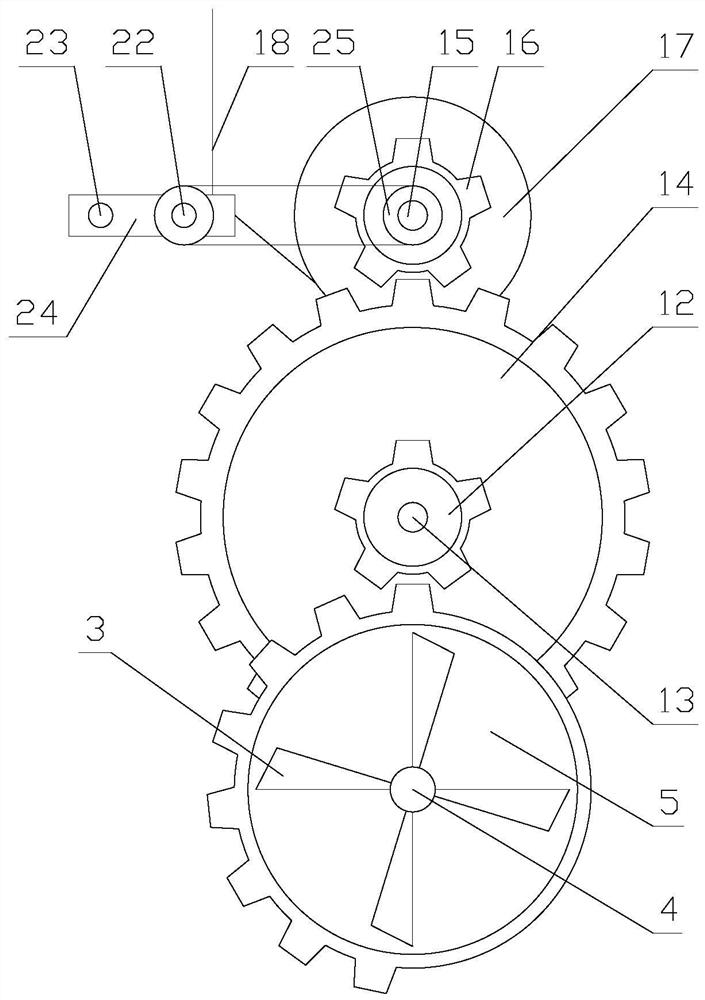

[0020] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

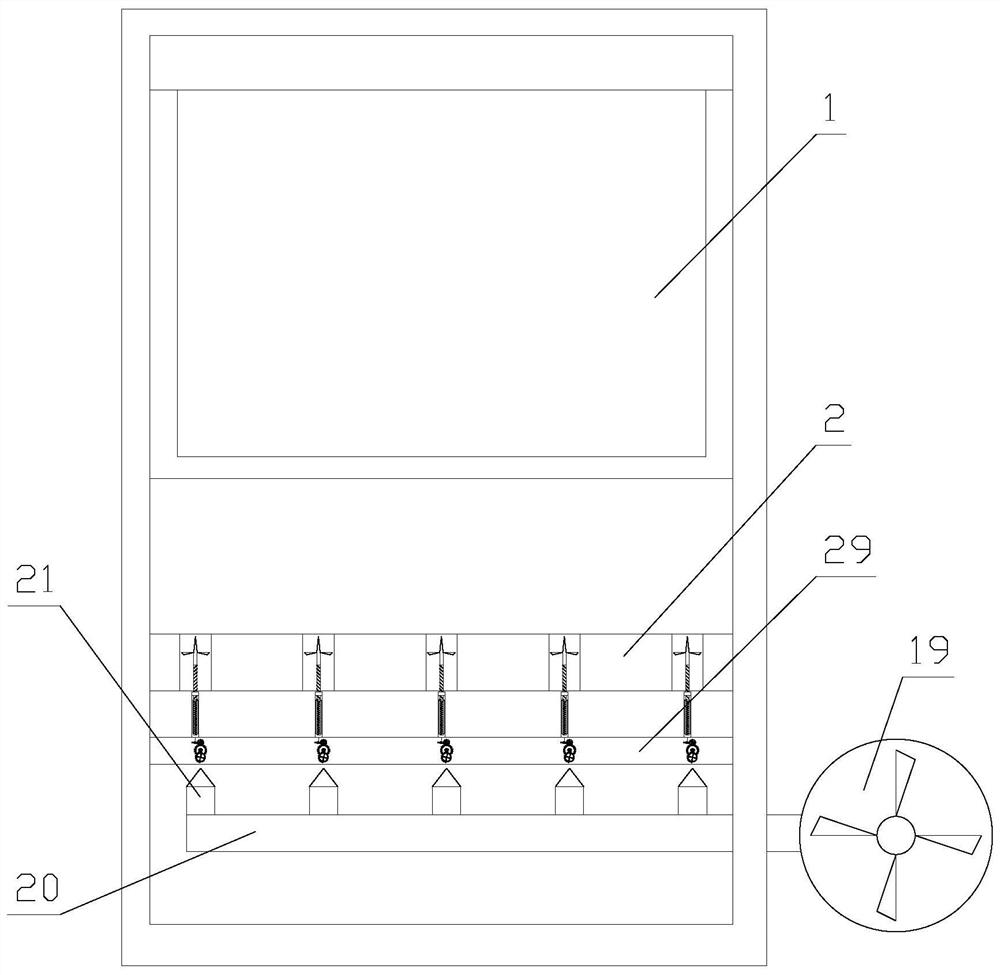

[0021] like figure 1 As shown, a boiler that prevents the clogging of vent holes includes a main body 1, a bottom plate 2, an air blowing mechanism and a dredging mechanism. The gas mechanism is arranged under the bottom plate 2, and the dredging mechanism is arranged in the main body 1. There are several dredging mechanisms, and each dredging mechanism is set correspondingly to each vent hole;

[0022] When the device is in use, put the coal on the bottom plate 2, then burn the coal, heat the water in the pot, blow air into the main body 1 through the air blowing mechanism, increase the oxygen concentration, and achieve a better combustion effect. Avoid clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com