Shale uniformly-crushing device for energy-saving type sintered shale hollow block

A hollow block and crushing device technology, applied in the direction of grain processing, etc., can solve the problems of blocked channels, increased costs, and blockages, and achieve the effects of solving blockages, avoiding raw material transfer, and fast feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

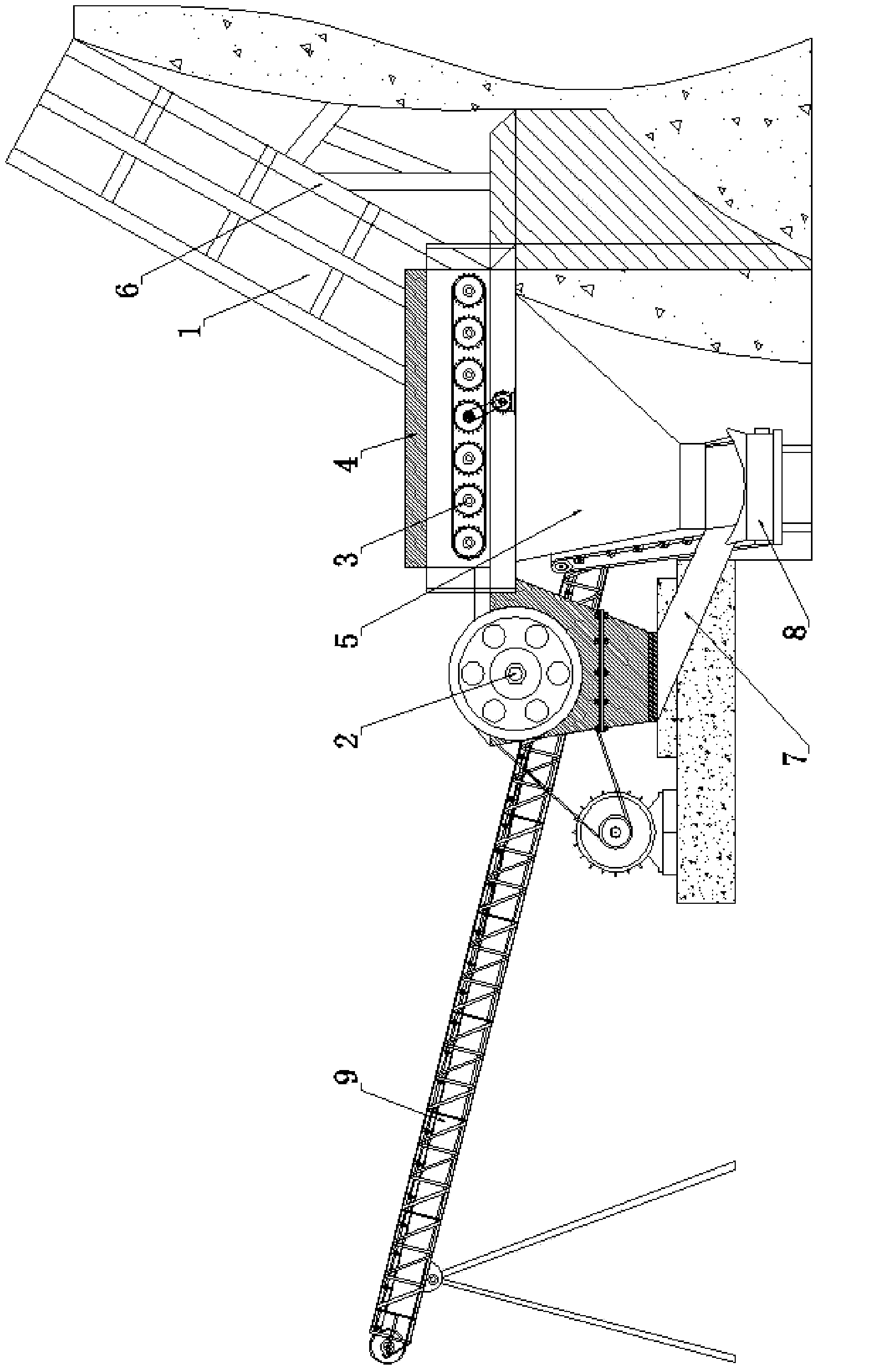

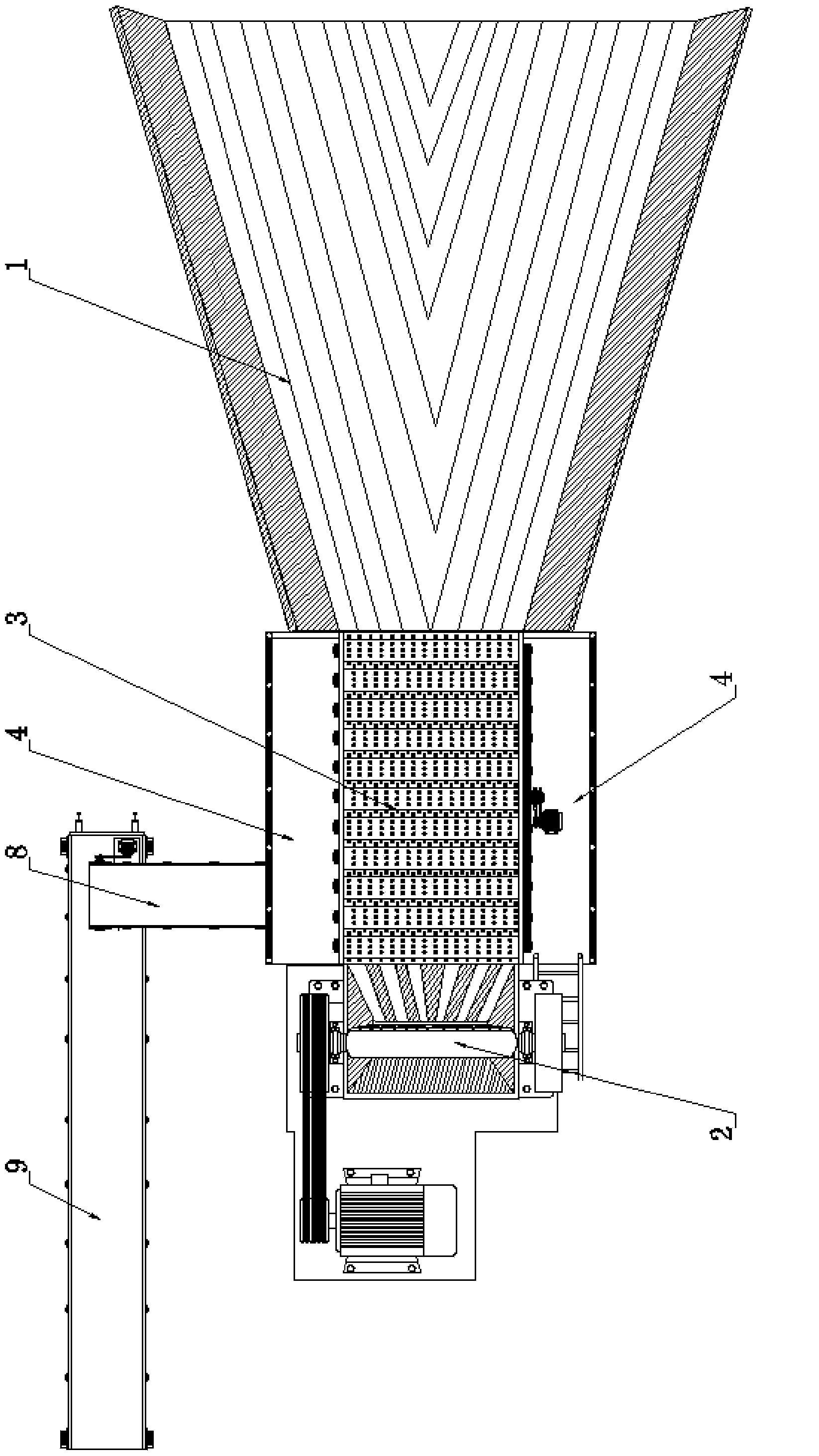

[0030] Such as figure 1 with figure 2 As shown, an energy-saving sintered shale hollow block shale homogenizing crushing device includes a crusher 2, and a feeding sieve 1 is arranged above the side of the crusher 2, and the feeding sieve 1 is in the shape of a large upper In the shape of a small groove, a feeder 3 is arranged between the feeding sieve 1 and the crusher 2. The inlet end of the feeder 3 corresponds to the outlet of the feeding sieve 1. The feeding The outlet end of the crusher 3 corresponds to the feed port of the crusher 2, and an operating platform 4 is arranged above the feeder 3, and the notch of the feeding sieve 1 faces the operating platform 4. A discharge machine 8 is arranged below the machine 3, and the transfer direction of the discharge machine 8 is perpendicular to the transfer direction of the feeder 3, and the outlet se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com