Coal mine quality detection device

A detection device, coal mine technology, applied in the direction of measurement device, fuel oil test, material inspection product, etc., can solve the problem of affecting the test result of the sample, without automatic cleaning device, etc., achieve fast cleaning and drying, and improve the blasting efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The following detailed description will be further described below in conjunction with the drawings to enable those skilled in the art.

[0033]It should be understood that, such as "having", "" ",", and "including" the terms used herein do not exclude presence or addition of one or more other elements or combinations thereof.

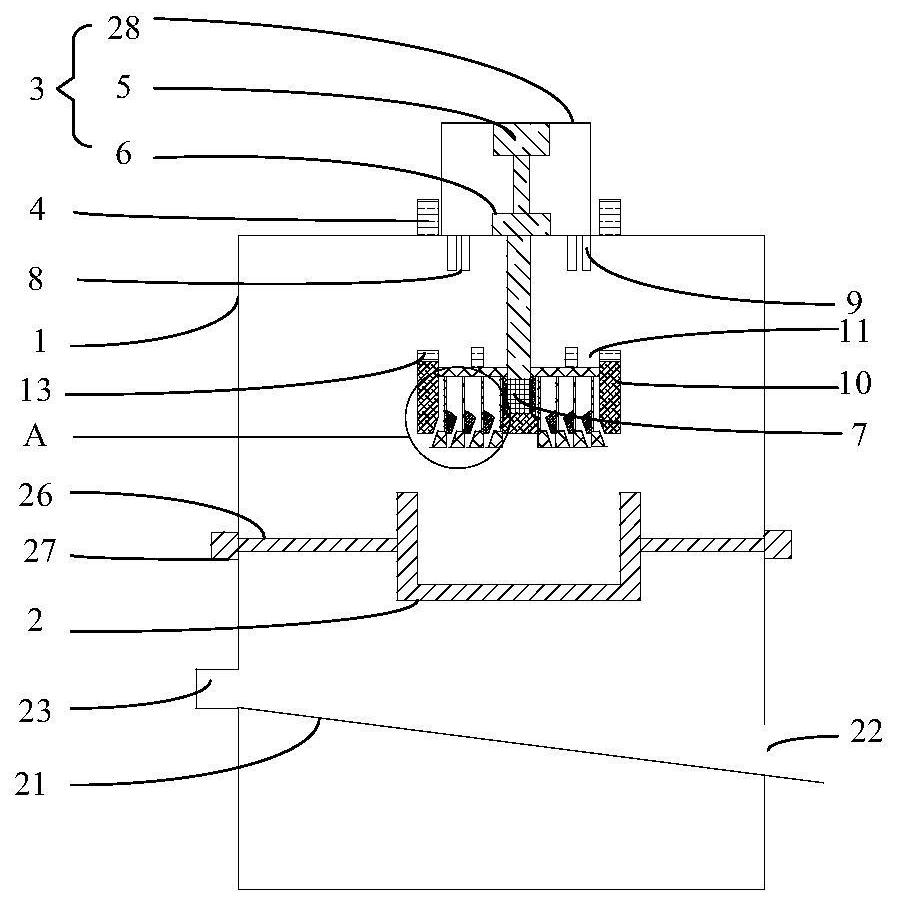

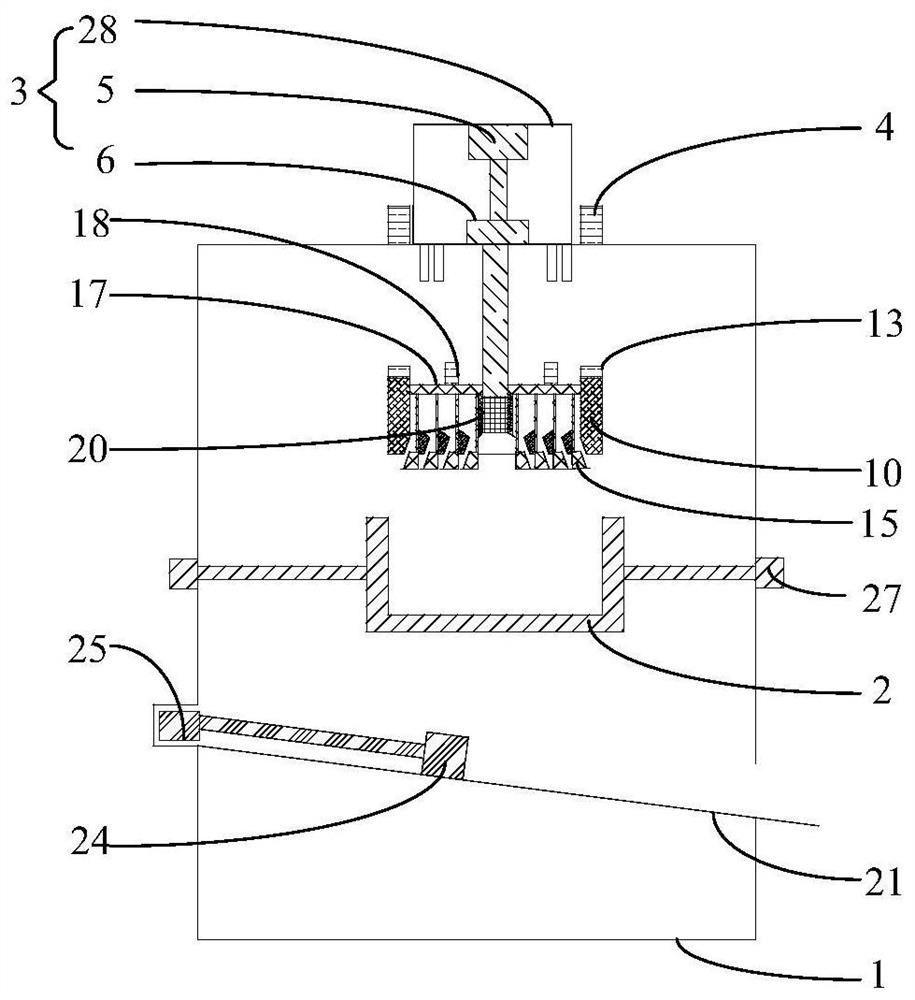

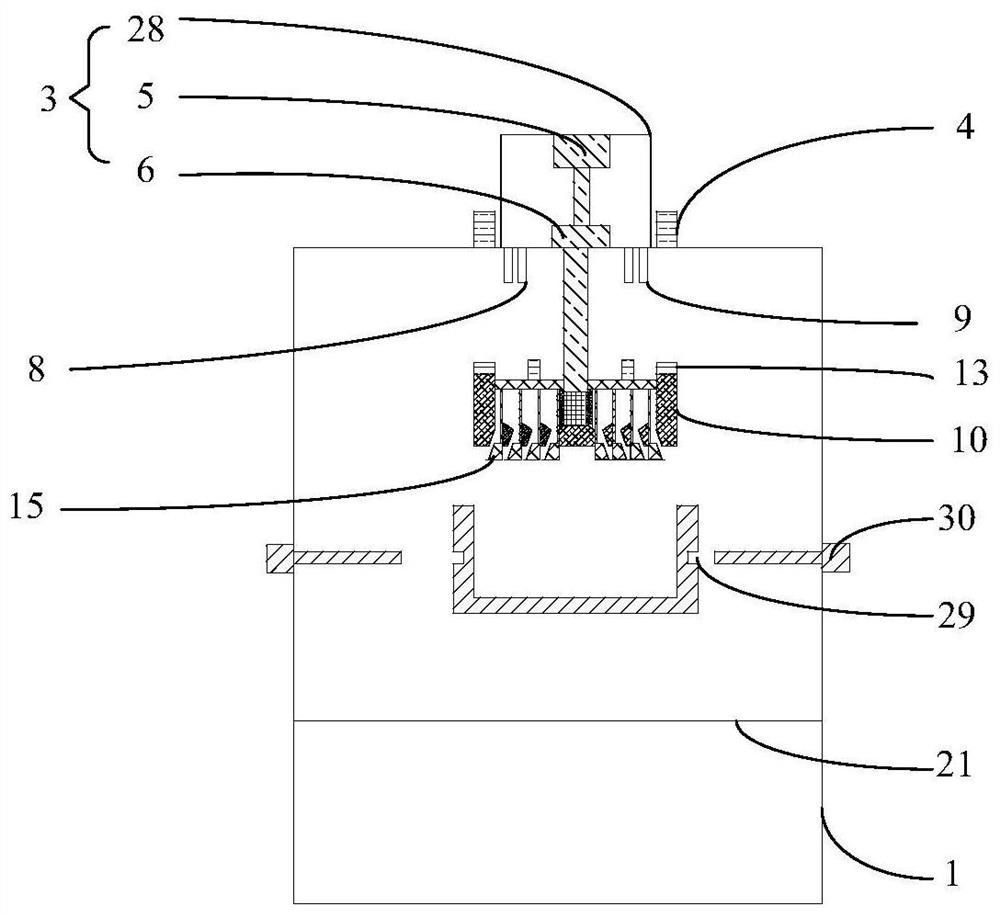

[0034]Such asFigure 1-4As shown, the present invention provides a coal mine mass detecting device including:

[0035]The housing 1, its internal space is a rectangular shape, and a rotatable grinding bowl 2 is provided in the inner portion of the housing 1, and the grinding bowl 2 is a top-open column shape, the outer top surface of the housing 1 At least one spray head 8 and at least one blast tube 9 are provided with an exit face;

[0036]The grinding block 10 is a cylindrical shape, and is adapted to the grinding bowl 2, and is located above the grinding bowl 2, the top surface of the grinding block 10 is formed downwardly to form a columnar cavity 11, the cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com