Multipoint gas monitoring device

A gas monitoring and gas detection technology, which is applied in the direction of measuring devices, sampling devices, sampling, etc., can solve the problems of gas pollution, large volume of gas samplers, and influence on accuracy, and achieve low cost, high measurement accuracy, and volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments will specifically illustrate the multi-point gas monitoring device of the present invention in conjunction with the accompanying drawings.

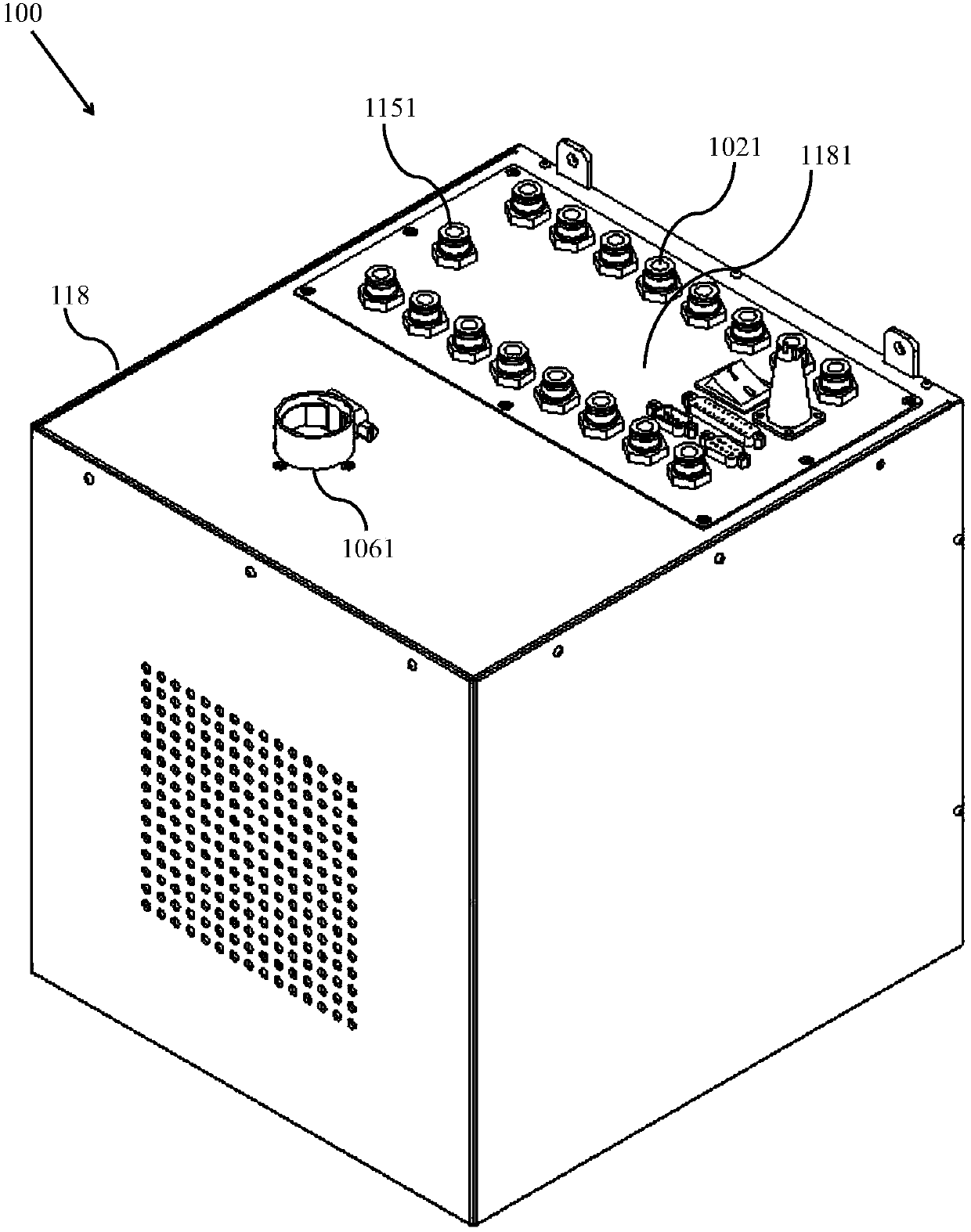

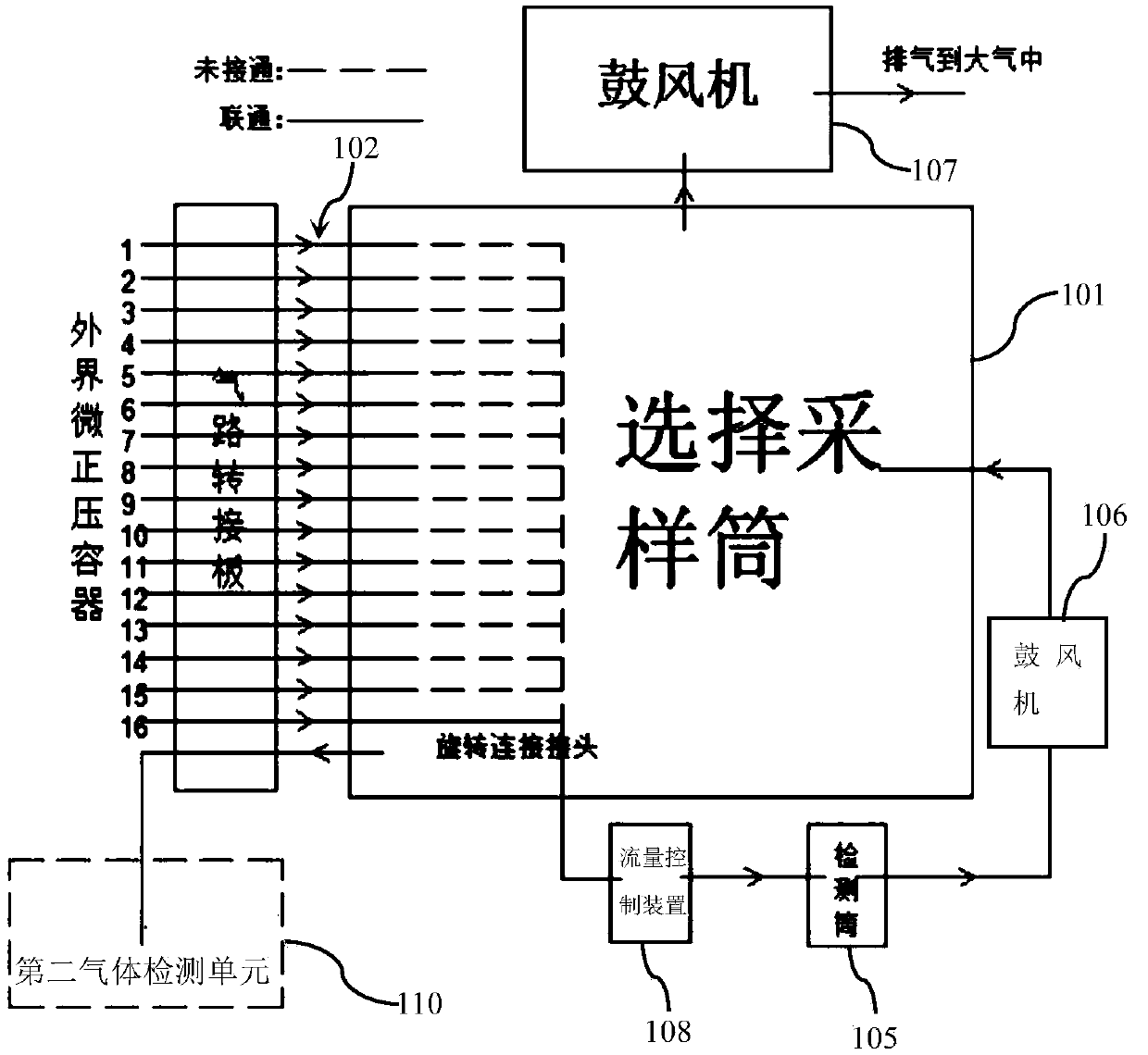

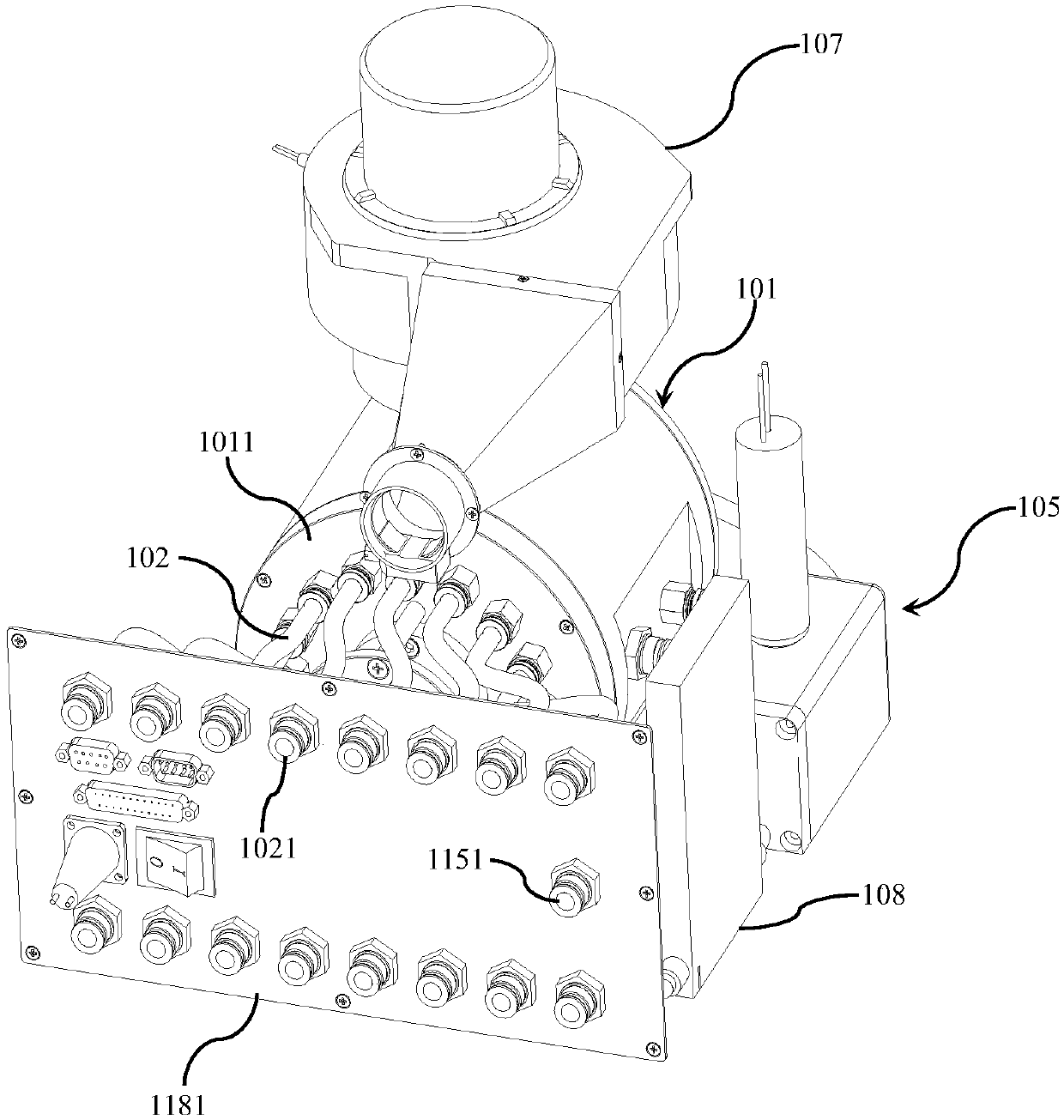

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the multi-point gas monitoring device 100 is used to monitor the water oxygen value and cleanliness of gas at multiple monitoring points. The multi-point gas monitoring device 100 includes: a selection sampling cylinder 101, a plurality of sampling connecting pipes 102, a rotating connecting pipe 103, a driving part 104, a first gas detection unit 105, a first power unit 106, a second power unit 107, a flow control Unit 108.

[0035] A plurality of sampling connection pipes 102 communicate with the selection sampling cylinder 101, one end of each sampling connection pipe 102 is connected with the air intake surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com