Feeding device for spray type refractory material spray coating machine

A technology for refractory materials and spraying machines, which is applied in the direction of conveyors, transportation and packaging, and conveying bulk materials. Simple, easy to disassemble and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

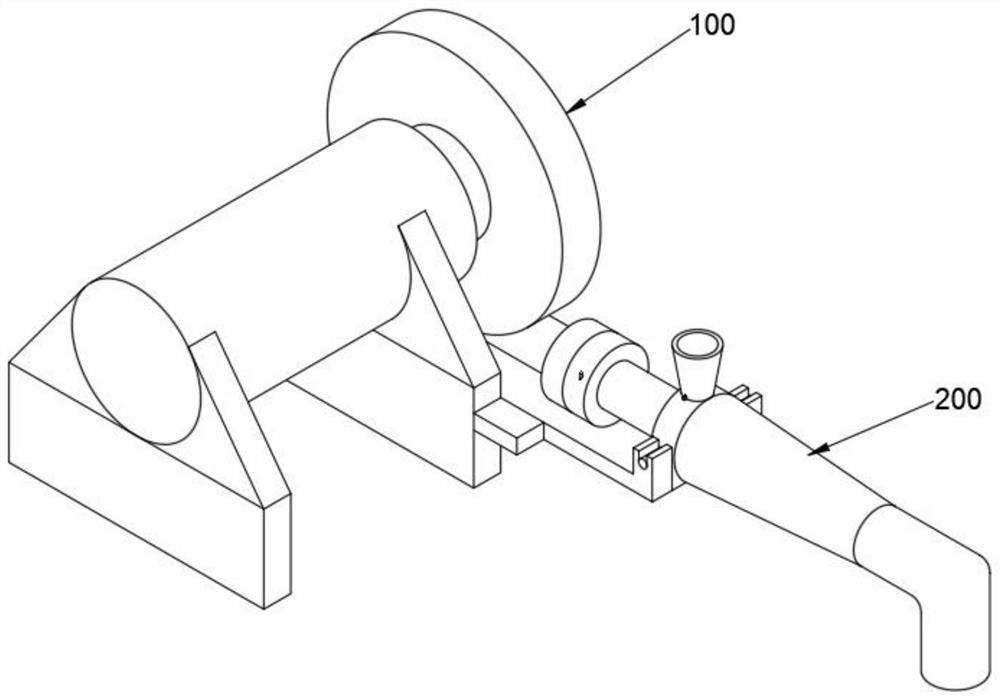

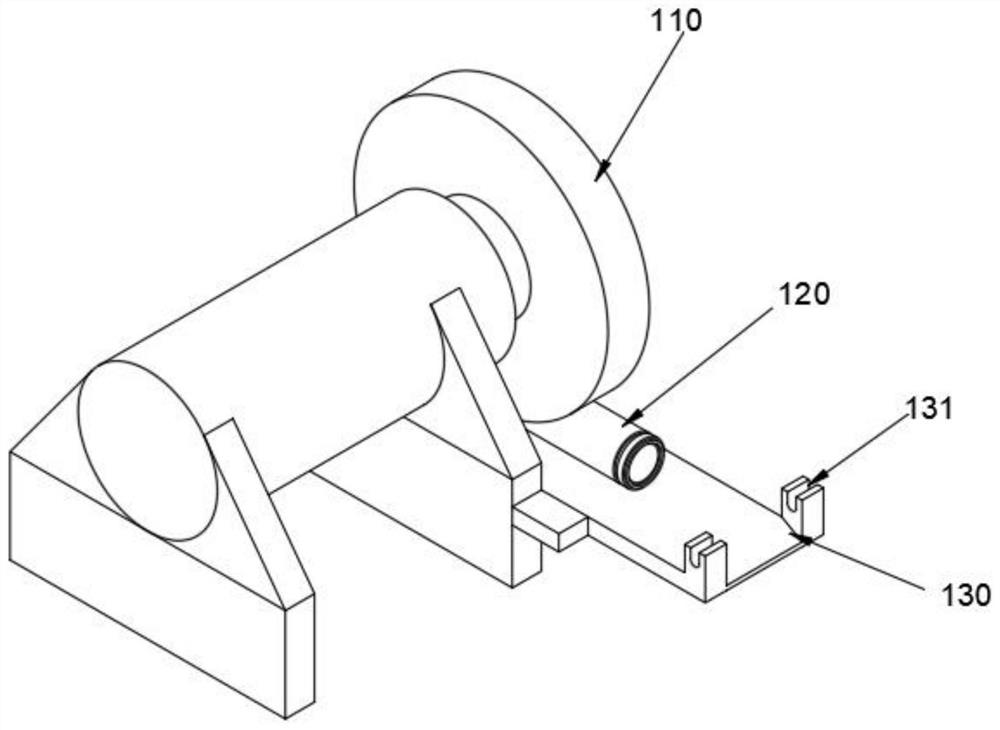

[0060] see Figure 1-Figure 16 As shown, the purpose of this embodiment is to provide a blanking device based on a spray-type refractory material spraying machine, including an air supply mechanism 100 for providing high-pressure air, and the air supply mechanism 100 is connected to a feeding mechanism 200 for feeding;

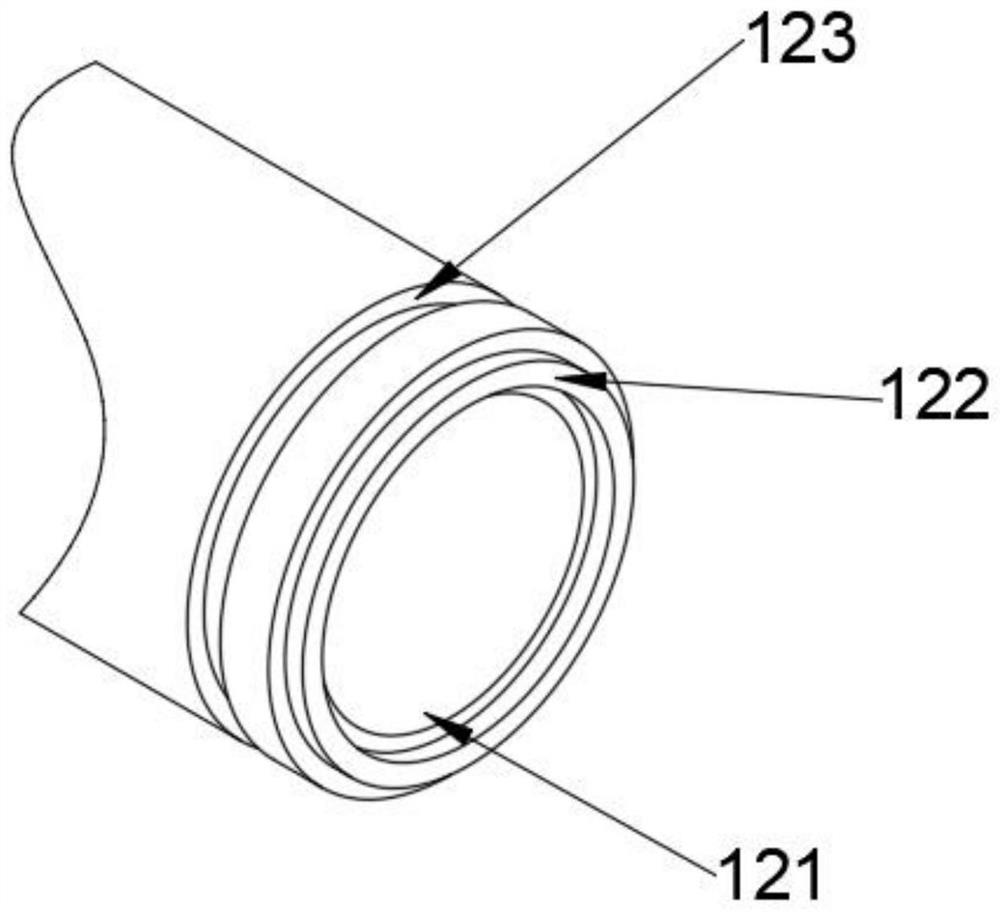

[0061] The blower mechanism 100 includes a blower 110 for generating high-pressure air. The blower 110 is connected with a blower pipe 120 for sending out high-pressure air. The other end of the blower pipe 120 is provided with a blower port 121. 122. The No. 1 air-tight gasket 122 is made of rubber material, which can play a sealing role to prevent air leakage. The surface of the blast pipe 120 is provided with a No. 1 sealing groove 123, and the No. 1 sealing groove 123 is an annular groove structure. A No. 1 connecting device 140 is installed in the sealing groove 123, and the inner wall of the No. 1 connecting device 140 is provided with a No. 1 snap-in bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com